5-52

CHAPTER 5 Periodic Inspection

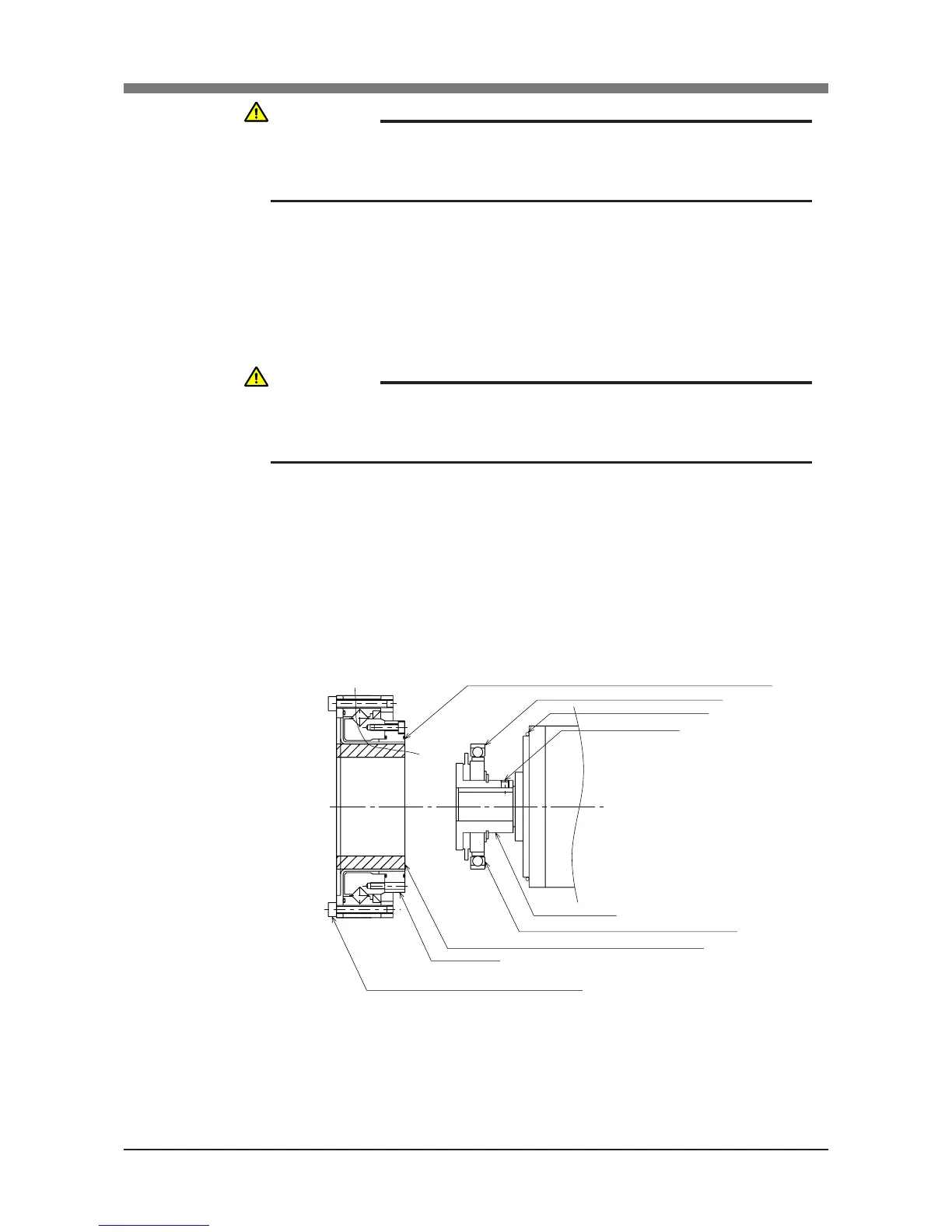

15) Fit an O-ring (supplied with the harmonic drive) coated with harmonic

grease into the O-ring groove on the new harmonic drive. (See Fig. 5-45.)

16) Secure the Y-axis arm to the harmonic drive with the bolts (M4×20L, 16

pieces) you removed earlier. Apply small amounts of “Screw Lock” to the

bolts and tighten them uniformly to secure the Y-axis arm. (See Fig. 5-42.)

17) Apply harmonic grease to the new wave generator and exible spline.

See Fig. 5-45 for applying grease properly.

18) Fit the wave generator onto the motor shaft, and fully insert it against the

motor. Then, apply small amounts of “Screw Lock” to the M4 set screw (1

piece) you removed earlier and tighten it to secure the wave generator.

(See Fig. 5-45.)

Fit O-ring (supplied) into this groove

Harmonic drive will be damaged if O-ring is caught out of groove.

O-ring : KN5-M257L-000

Apply grease to entire oldham coupling.

O-ring : KN5-M2143-000

M4 set screw

Wave generator

Apply grease to sufficiently fill in the ball space.

Apply grease to the thickness equal to the ball diameter.

Circular spline

Never remove these temporarily tightened bolts.

The axis will otherwise deviate from center.

Fig. 5-45

CAUTION

DO NOT ALLOW THE O-RING TO GET CAUGHT OUT OF THE GROOVE

DURING REASSEMBLY. A TROUBLE WILL OCCUR IF THE ROBOT IS

OPERATED WITH THE O-RING LEFT CAUGHT OUT OF THE GROOVE.

CAUTION

DO NOT ALLOW THE O-RING TO GET CAUGHT OUT OF THE GROOVE

DURING REASSEMBLY. A TROUBLE WILL OCCUR IF THE ROBOT IS

OPERATED WITH THE O-RING LEFT CAUGHT OUT OF THE GROOVE.

Loading...

Loading...