1500 North Belcher Road, Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-100 Flow Display Manual 08-12 - 0634-7 Page 23

4.6 COMMISSIONING

Upon initial installation, it is strongly recommended that both the D-100 and its associated ow

meter be commissioned to ensure that they are properly installed and functioning correctly.

This process involves verifying the mechanical installation, measuring ow signals and then

comparing these measurements to the specied installation and operating parameters listed on

the certicate of calibration provided with the display. The data collected during this initial

commissioning process will then serve as baseline data for periodic revalidation of the meter

operation.

COMMISSIONING PROCEDURE

Please read all installation instructions carefully before

proceeding. Wiring diagrams are located in this manual.

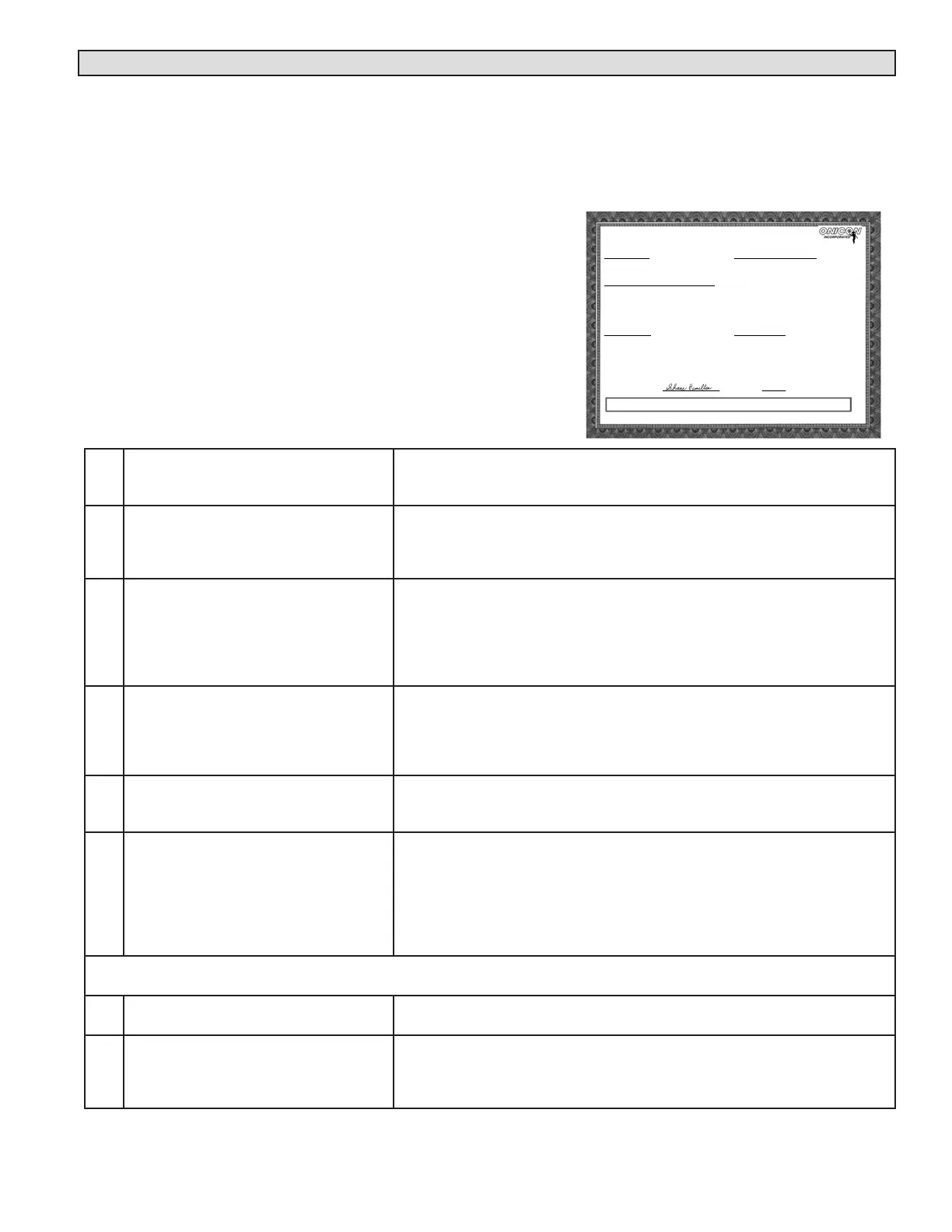

Use the display Certicate of Calibration to verify that

the specied installation & operating parameters match

the actual conditions at the location where the display

is installed. A worksheet for checking these steps and

recording measured values is located on the following

page.

1. Conrm that the D-100 is being

installed with the correct ow meter

and any optional sensors.

Check the label inside the front cover of the D-100 and conrm that the

serial numbers match the serial numbers of the ow meter and any optional

sensors being used.

2. Conrm that the D-100 is being

installed in accordance with

Sections 1.5 and 3.1 of this manual.

Conrm that the installation location is not in direct sunlight and is

removed from sources of strong electrical interference. The display should

be mounted on a vibration-free surface where it will be protected against

spraying, splashing and the seepage of water.

3. Conrm the pipe diameter and pipe

material.

Conrm that the ow meter is tagged for the pipe diameter and material in

which it is to be installed and that this information matches the information

provided on the display certicate of calibration. When in doubt, measure

the circumference of the pipe.

PipeO.D.=(circumference/3.14)–(insulationthicknessx2)

4. Conrm that the ow meter installation

conforms to the requirements specied

in the ow meter installation manual.

Verifythattheowmeterisinstalledinalocationwithenoughstraight

unobstructed run upstream and downstream of the pipe. Also verify that

the ow meter is properly oriented with respect to ow direction, and for

insertion meters ensure that the meter is installed to the correct insertion

depth.

5. Conrm that any optional sensors are

properly installed.

VerifythatanyoptionalsensorsconnectedtotheD-100areinstalledin

accordance with the manufacturer’s installation instructions. Also conrm

that the sensor output matches the information shown on the D-100 C of C.

6. Conrm that the correct supply voltage

has been provided.

VerifyandmeasuretheACinputvoltagetothedisplay.

Input voltages should be within the following ranges.

24VAC:20–28VAC

24VACwhenconnectedtoanF-3500andtheD-100isequippedwitha

multi-analogboard:21.6–28VAC

120VAC:108-132VAC

230VAC:207-253VAC

In order to proceed with the following steps, the display, ow meter and optional sensors must be operating and there must

be ow in the pipes. Flow signal readings should be taken while holding the ow rate constant, if possible.

7. Select the ow rate page on the D-100

front panel display.

ScrollthroughtheD-100displaypagesandselecttheowratepage.Verify

that the engineering units and multiplier shown match those on the C of C.

8. Note and record the ow reading. Note the displayed ow rate and conrm that it is within the expected

range. For D-100 displays connected to ow meters with integral displays,

conrm that the ow readings shown on the two displays agree. Record the

ow rates.

INTEGRATED D-100 DISPLAY

CERTIFICATE OF CALIBRATION

METER INFORMATION

Meter Tag:

BTU Meter Model: SYSTEM-30

Serial No: 134036

SPECIFIED INSTALLATION & OPERATING PARAMETERS

Pipe Information: 1 Inch Copper Tube

Design Maximum Flow Rate: 40.0 GPM

Design Supply Temperature: MODE 1: 45°F

Design Return Temperature: MODE 1: 55°F

Fluid: 25% Ethylene Glycol

Fluid Specific Heat: 0.885 BTU/lb°F

Fluid Density: 65.06 lb/ft³

CONFIGURATION DATA

Enclosure Type:

Input Supply Voltage: 24 AC/DC

Thermowell Type:

CALIBRATION AND PROGRAMMING DATA

Firmware Version: CFM4.6S30

Communications Protocol:

Device Network Address:

Flow Sensor MF Code: 547.500

Programmed Units & Multipliers:

Energy Total: BTU x 1K Energy Rate: BTU/HR x 1K

Flow Total: GAL x 10 Flow Rate: GPM x 1

Temperature: °F

Damping: 5

Pulse Duration: 500 ms

Supply Temperature Slope: 9.969 Offset: -0.870

Return Temperature Slope: 10.004 Offset: -0.130

OUTPUT SIGNAL SCALING

Energy Total(s): 1 Pulse = BTU x 1K

Flow Rate: NA

Energy Rate: NA

Supply T: NA

Return T: NA

Delta T: NA

Calibrated By: Date: 09/01/2004

1500 North Belcher Road, Clearwater, Florida 33765 Tel (727) 447-6140 Fax (727) 442-5699

ONICON Incorporated certifies that the flow and temperature sensors provided with this Btu meter have been individually calibrated based on the

a

lication s

ecific data

rovided above

usin

standards directl

traceable to the U.S. National Institute of Standards an

Technolo

N.I.S.T.

.

Shane Hamilton

Loading...

Loading...