OPTIMUM

MASCHINEN - GERMANY

Anomalies

© 2008

GB

Page 494 February 2008 version 1.3.1 S210G; S275G; S210G Vario; S275G Vario Metal belt saw

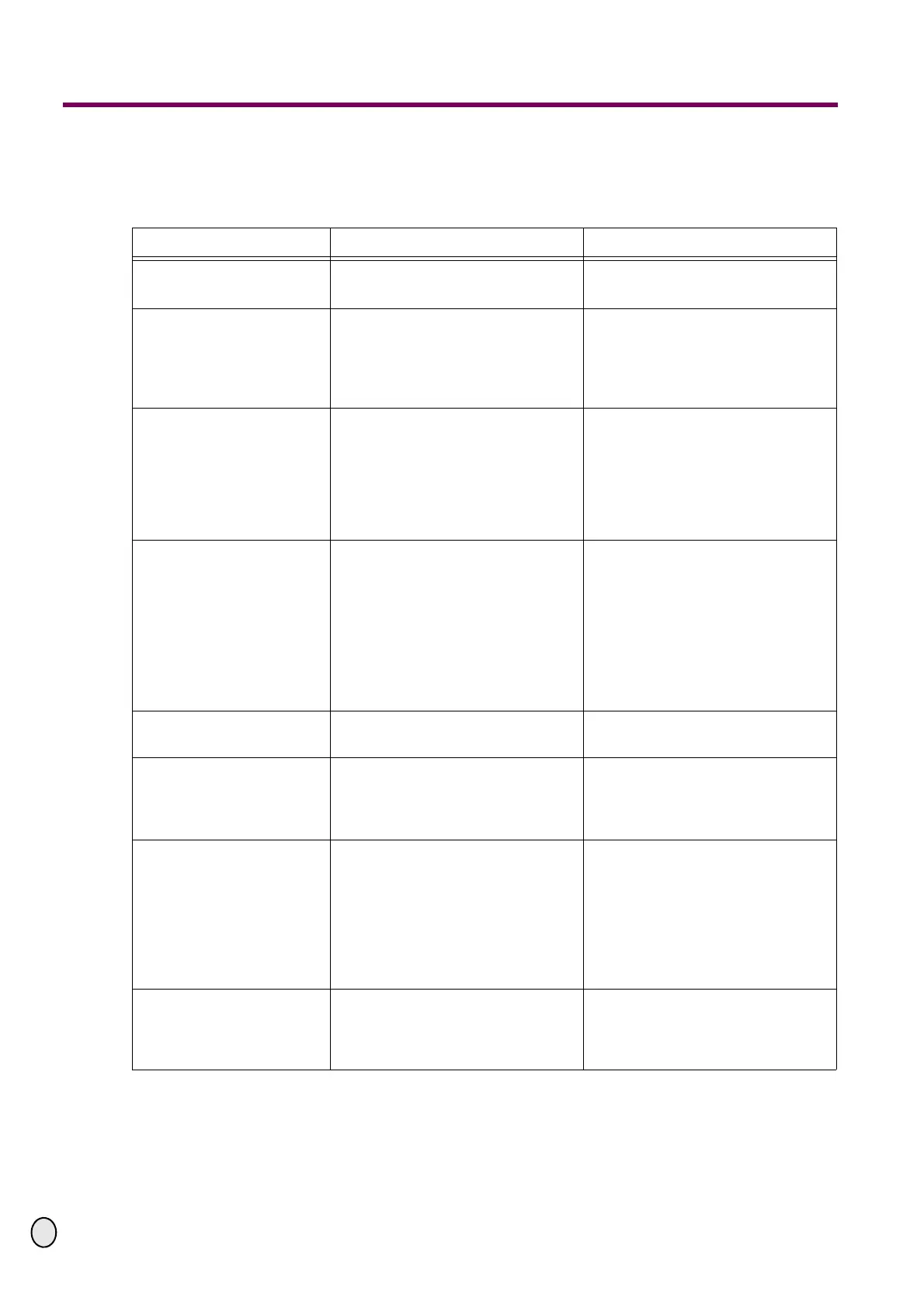

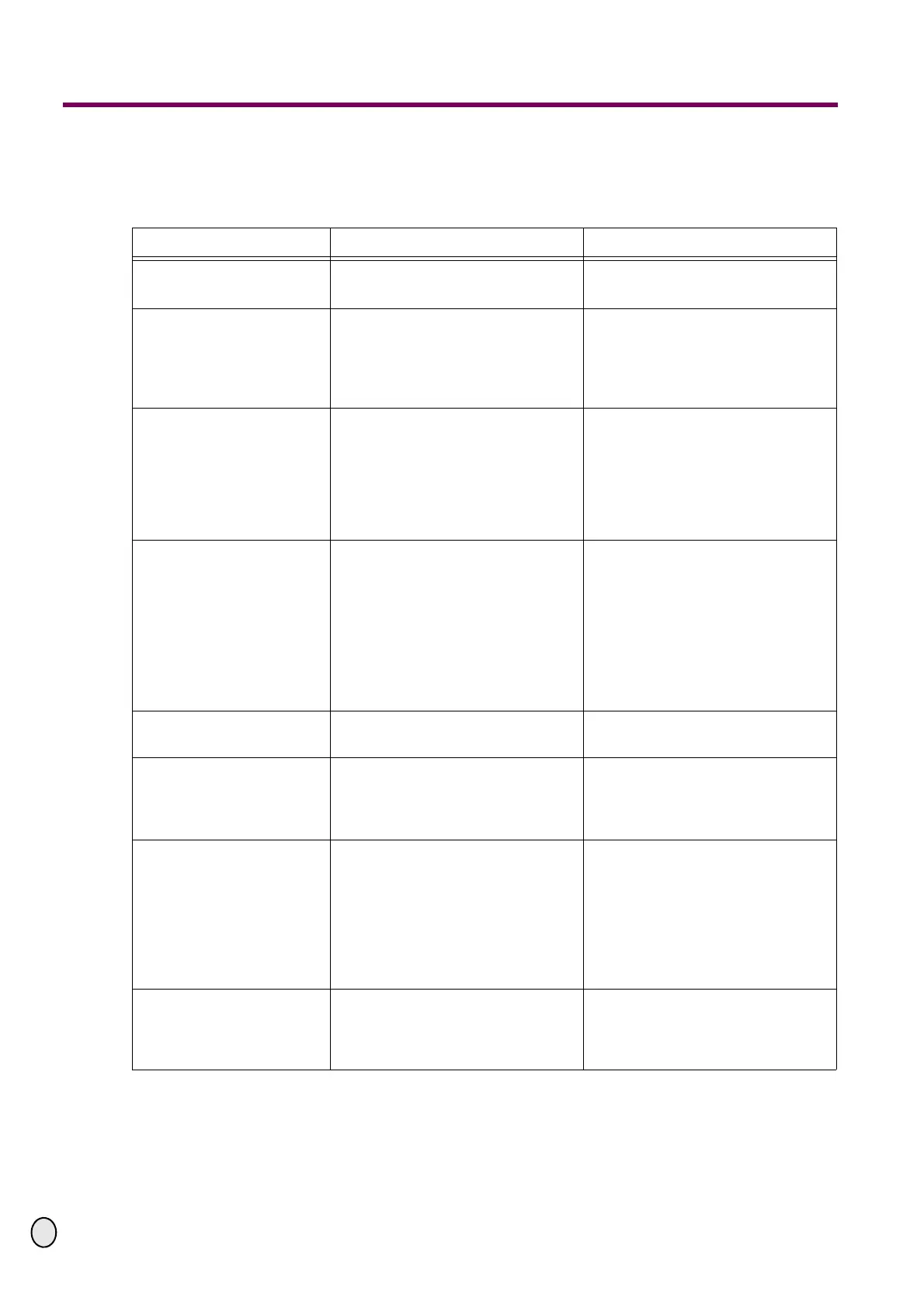

8 Anomalies

8.1 Anomalies in the metal belt saw

Anomaly Cause / possible effects Suggested solution

Maschine does not run on • The FI protected switch of your

electrical supply release.

• “Power connection“ on page

20

Saw motor overloading

• Suction of motor cooling air hin-

dered

• Motor not correctly fixed

• Power unit for saw belt not prop-

erly fixed

• Check and clean

• Requires technical service! Have

the machine repaired in the work-

shop

Cooling agent feed not

working

• Cooling agent tank empty

• Cooling agent tap closed

• Cooling agent tap blocked

• Cooling agent duct bent or blocked

• Air in the system, e.g. after re-fill-

ing

• Pump doesn't work

• Fill

• Open

• Clean

• Check and clean

• Bleed by briefly withdrawing the

pressure hose

• Check pump

Short life of saw belt

(Teeth blunted)

• Quality of saw belt not suitable for

this material

• An incorrect tooth spacing causes

breakage of teeth (the broken

tooth in the work piece blunts the

other teeth)

• Missing cooling

• Cutting speed too high

• Feed too high

• Higher quality saw belt (choose

bimetallic belt)

• Select correct tooth spacing

• Use cooling system

• Reduce cutting speed

• Reduce feed

Breakage of teeth

• Chip space in the saw belt full,

tooth spacing incorrect

• Use saw belt with a different tooth

spacing or reduce feed

Breakage of the saw belt

• Tension in the saw belt too high or

too low

• Saw belt defective

• Saw belt guide adjusted incorrectly

• Check tension of the saw belt

•Replace

• Adjust saw belt guide correctly

Twisted cut (saw belt devi-

ating

)

• Distance between guide and work-

work piece too high

• Saw belt blunt

• Saw tension too low

• Feed too high

• Cutting pressure too high

• Saw belt defective (irregular set)

• Saw blade guide badly set

• Bring the guide as close as possi-

ble to the work piece

•Replace

• Tighten correctly

• Reduce

• Reduce

•Replace

• Readjust

Cut not rectangular, but

parallel

• Material does not rest on both rails

of the work-holder vice

• Clamps of the work-holder vice not

adjusted to 90º

• Support material properly

• Adjust clamps correctly

Loading...

Loading...