Modbus Communication 12-1

AC10 Inverter

Chapter 12 Modbus Communication

12.1 General

Modbus is a serial and asynchronous communication protocol. Modbus protocol is a general

language applied to PLC and other controlling units. This protocol has defined an information

structure which can be identified and used by a controlling unit regardless of whatever network

they are transmitted.

You can read reference books or ask for the details of MODBUS from manufactures.

Modbus protocol does not require a special interface while a typical physical interface is

RS485.

12.2 Modbus Protocol

12.2.1 Transmission mode

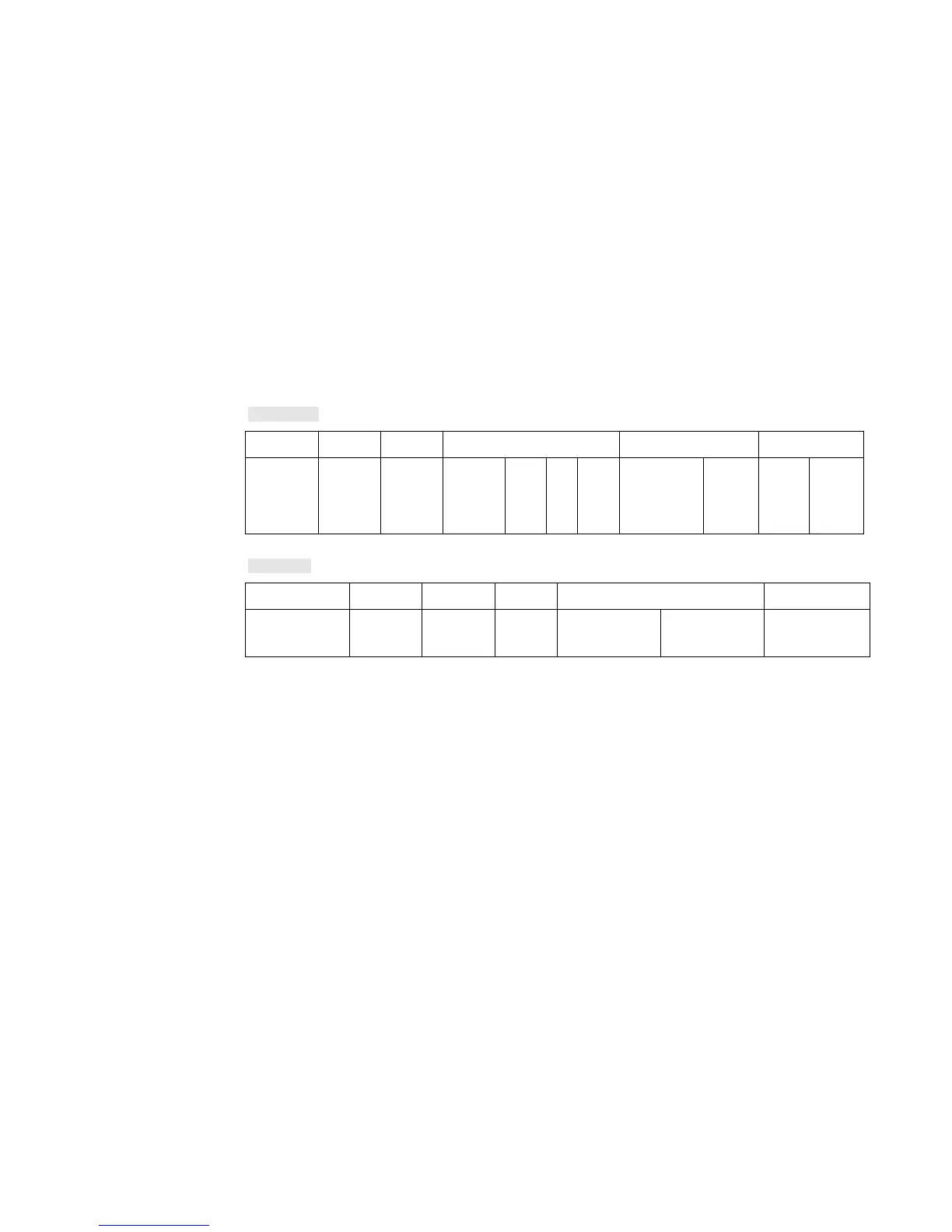

Format

ASCII mode

Start Address Function

Code

N data

Low-order

byte of CRC

High-order

byte of CRC

T1-T2-T3-T4

12.2.2 ASCII Mode

In ASCII mode, one Byte (hexadecimal format) is expressed by two ASCII characters.

For example, 31H (hexadecimal data) includes two ASCII characters’3(33H)’,’1(31H)’.

Common characters, ASCII characters are shown in the following table:

Characters ‘0’ ‘1’ ‘2’ ‘3’ ‘4’ ‘5’ ‘6’ ‘7’

ASCII Code 30H 31H 32H 33H 34H 35H 36H 37H

Characters ‘8’ ‘9’ ‘A’ ‘B’ ‘C’ ‘D’ ‘E’ ‘F’

ASCII Code 38H 39H 41H 42H 43H 44H 45H 46H

12.2.3 RTU Mode

In RTU mode, one Byte is expressed by hexadecimal format. For example, 31H is delivered to

data packet.

12.3 Baud rate

Setting range: 1200, 2400, 4800, 9600, 19200, 38400, 57600