180 KENR6933

Troubleshooting Section

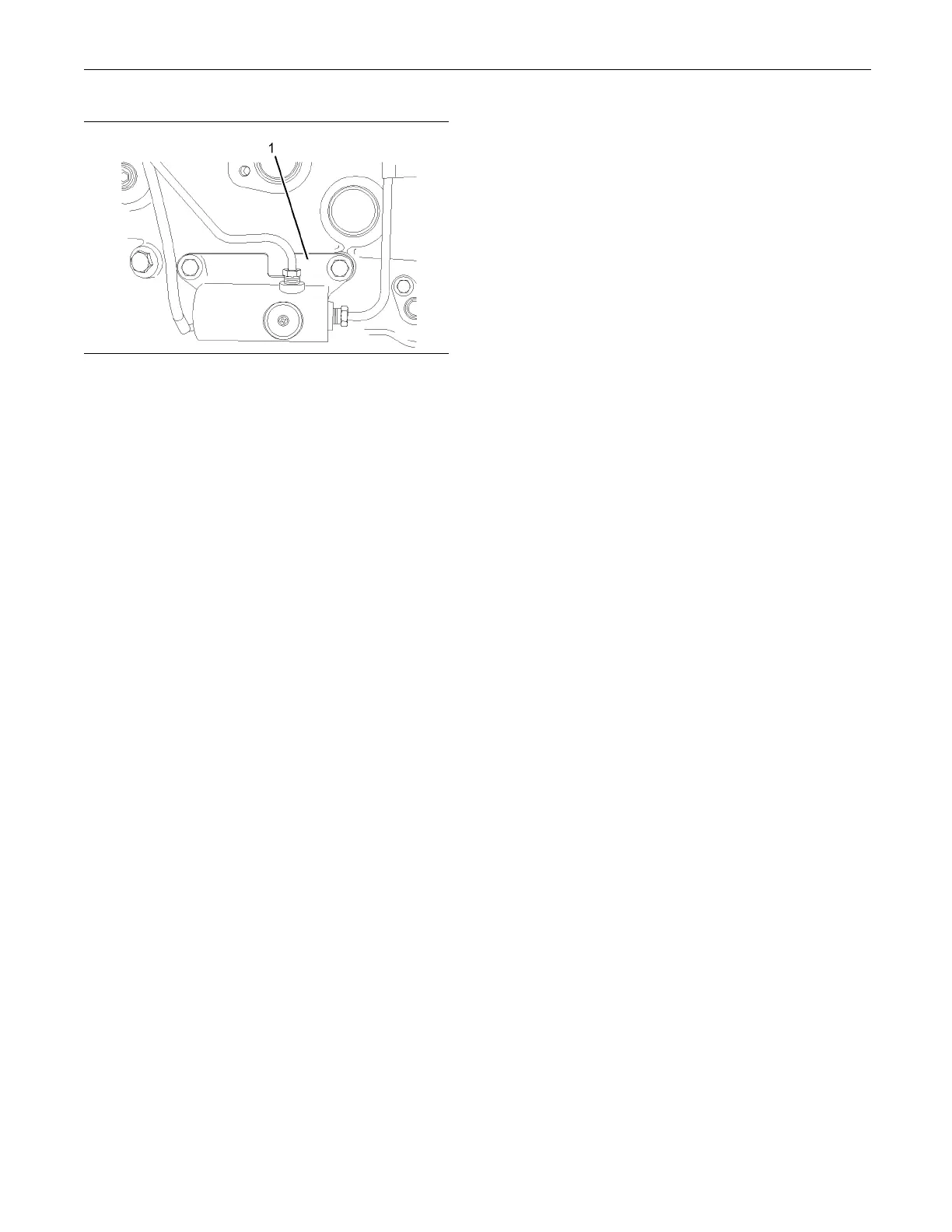

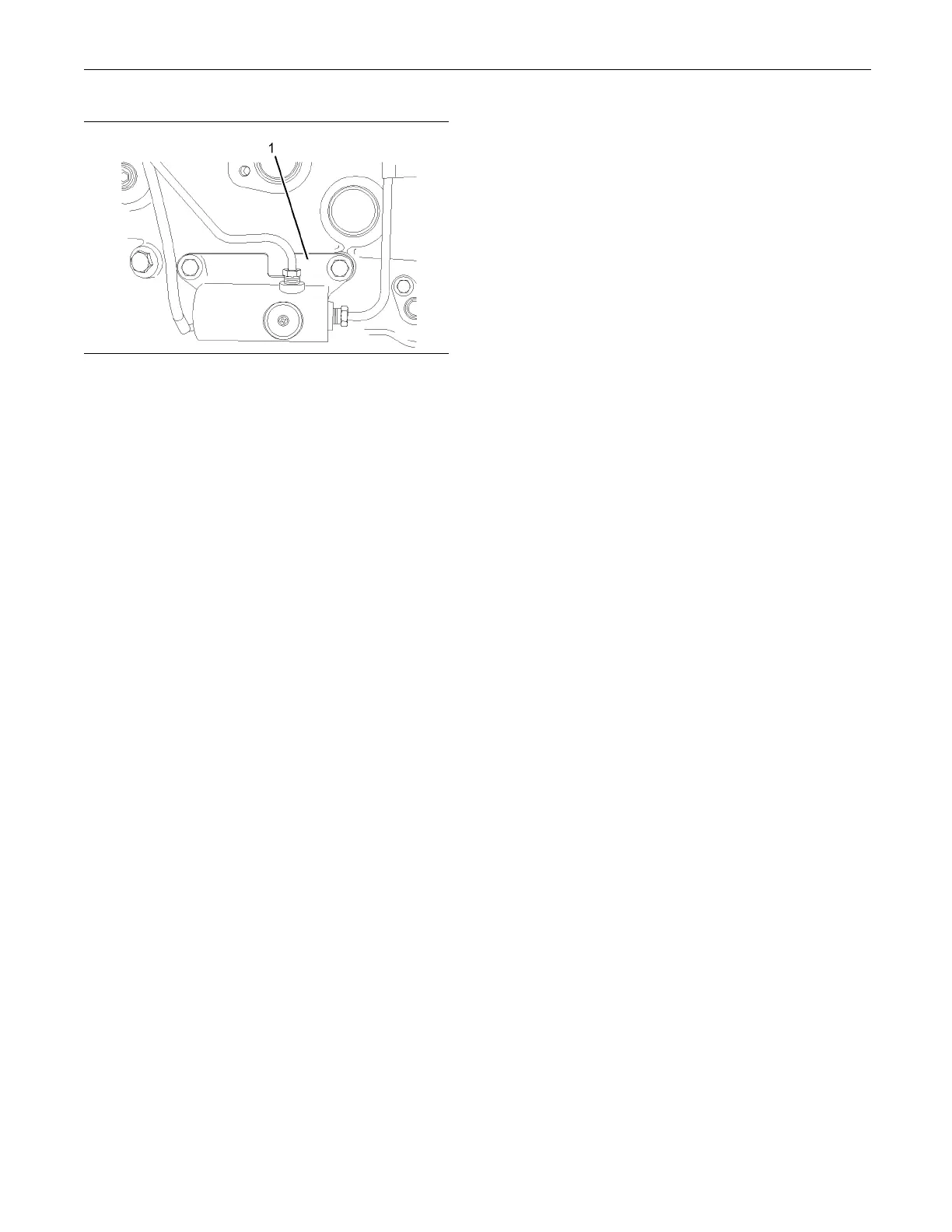

g01172794

Illustration 74

Wastegate regulator

(1) Wastegate regulator

Test Step 1. Check for Diagnostic Codes

A. Turn the keyswitch to the OFF position.

B. Connect the electronic service tool to the data link

connector.

C. Turn the keyswitch to the ON position. Start the

Perkins EST.

D. Monitor the electronic service tool for active

diagnostic codes and/or logged diagnostic codes.

Expected Result:

One or more diagnostic codes are active or logged.

Results:

•

Diagnostic codes 526-5 and/or 526-6 are active

and/or logged – Proceed to Test Step 2.

•

No Codes – The fault seems to be resolved.

Repair: For intermittent faults, refer to

Troubleshooting, “Electrical Connectors - Inspect”.

STOP.

Test Step 2. Insp ect Electrical Connectors

and Wiring

A. Thoroughly inspect the P2/J2 ECM connector and

the P511 connector for the wastegate regulator.

Refer to Troubleshooting, “Electrical Connectors -

Inspect” for details.

B. Perform a 45 N (10 lb) pull test on each of the

wires that are associated with the wastegate

solenoid.

C. Check the screw for the ECM connector for the

correct torque

of5.0N·m(44lbin).

Expected Result:

All connectors, pins, and sockets are completely

coupled and/or inserted and the harness is free of

corrosion, ab

rasion, and pinch points.

Results:

•

OK – The harness is OK. Proceed to Test Step 3.

•

Not OK – There i

s a fault in the connectors and/or

the harness.

Repair: Repai

r the connectors or the harness or

replace the connectors or the harness. Ensure that

all of the seals are correctly installed and ensure

that the conn

ectors are completely coupled.

Use the electronic service tool in order to clear all

logged diagn

ostic codes and then verify that the

repair eliminates the fault.

STOP.

Test Step 3. Determine the D iagnostic

Code that is Ac tive

A. T urn the keyswitch to the ON position. Access the

“Diagnostics Tests” on the electronic service tool.

Activate th

e “Turbo Wastegate Solenoid Test”.

Wait at least 30 seconds in order for the result to

be displayed.

B. Determine if the fault is related to either of the

following:

•

“Low current” (open circuit)

•

“High curr

ent” (short circuit)

Expected Result:

The electronic service tool displays no diagnostic

codes.

Results:

•

OK – There

are no active codes.

Repair: The original codes may have been caused

by a loose

connector. If this is an intermittent fault,

refer to Troubleshooting, “Electrical Connectors -

Inspect”.

STOP.

•

Not OK – Di

agnostic code 526-5 is active at this

time. Proceed to Test Step 4.

Loading...

Loading...