permaPRO-8-

4. Mounting and Assembly of the Lubrication System

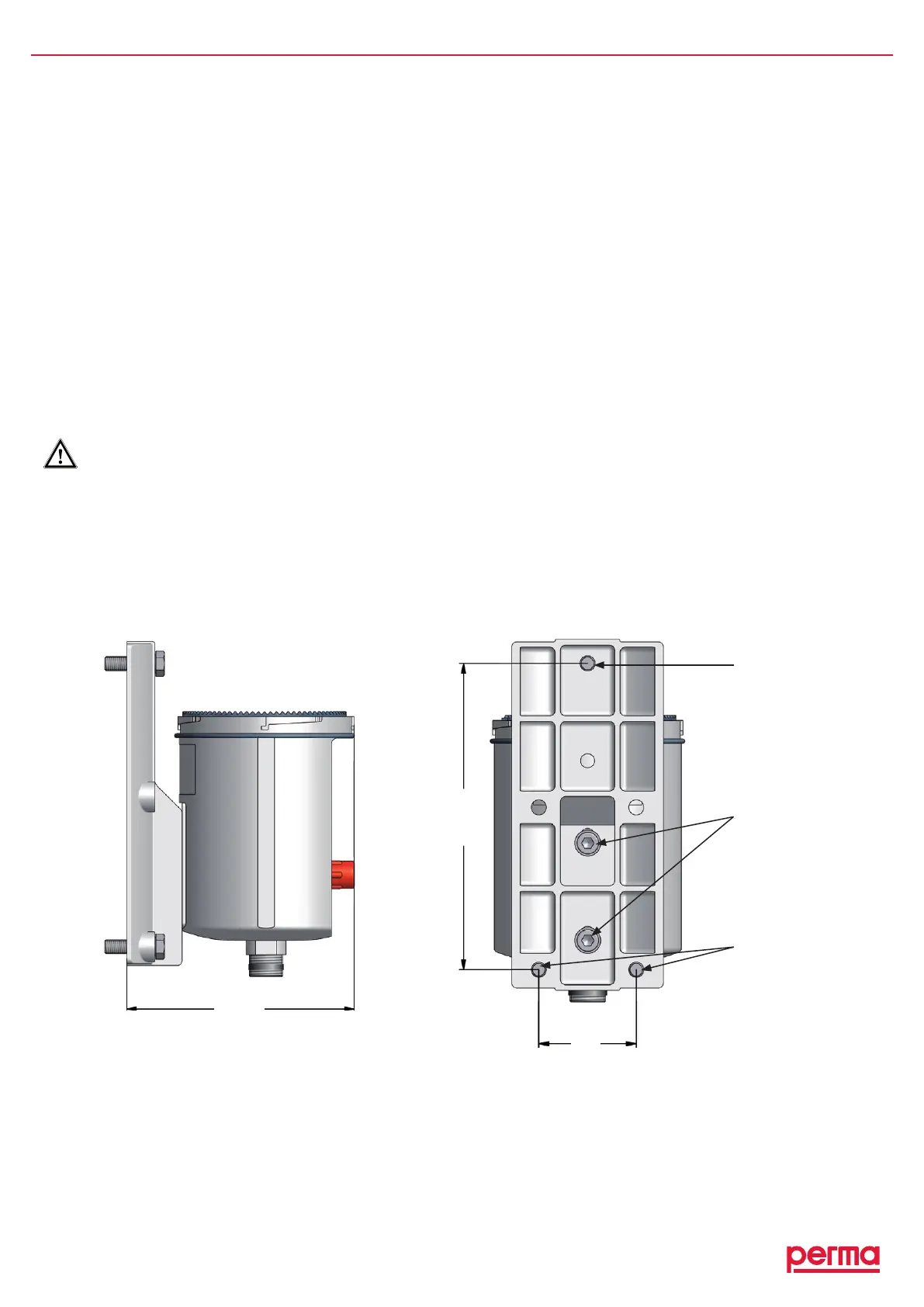

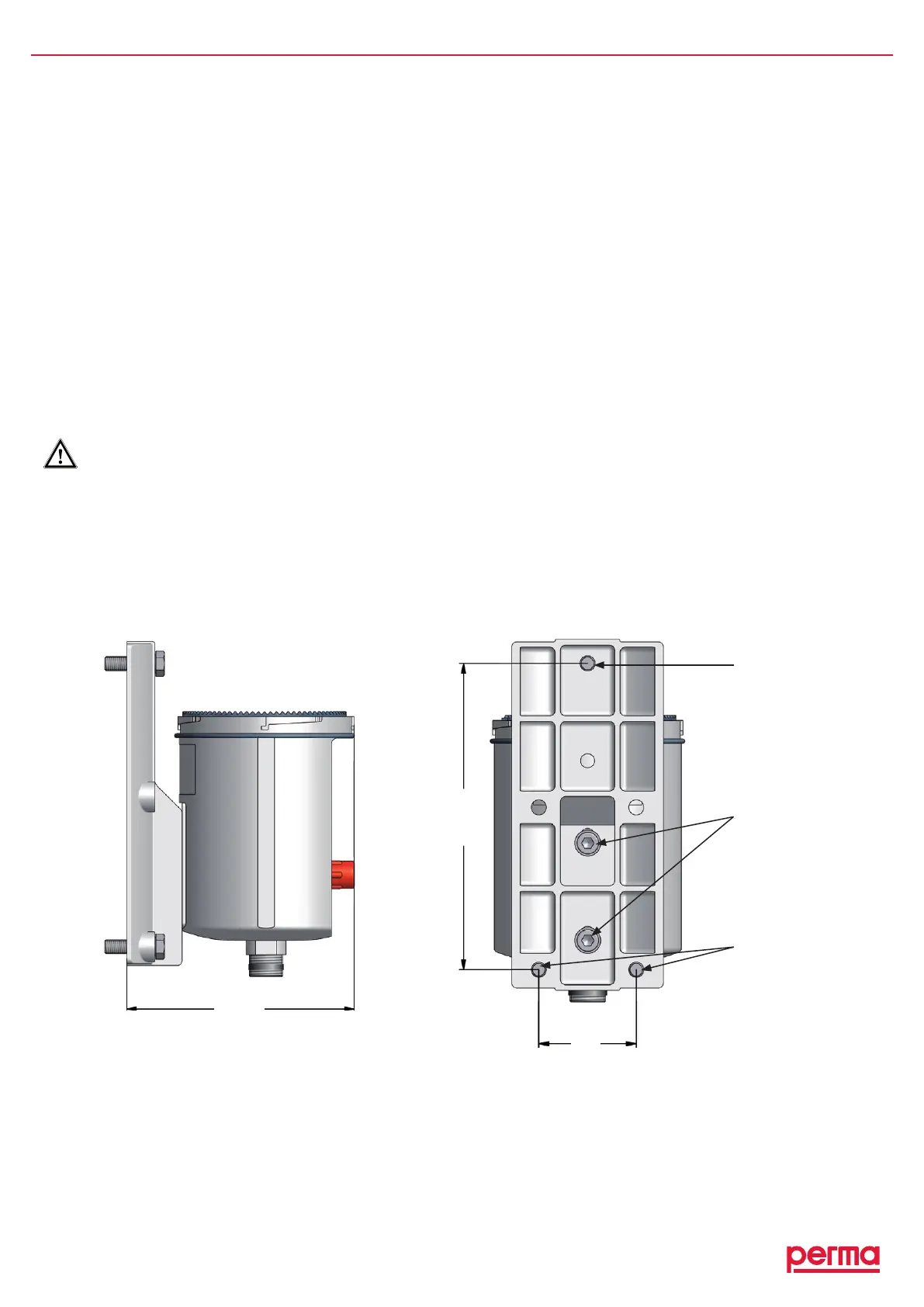

4.1 Mounting the Drive Unit onto a Fixing Device for Wall-Mounting

♦ Attachthesuppliedmountingdevicetothedriveunitusingthetwoenclosedhexheadbolts(M6x16)and

thetwowashers.

♦ Screwthemountingdevicewiththedriveunitontoasupportofyoursystem.

Theboringtemplateofthethreemountingscrews(141.5x45)canbeseenbelowingure3oronthe

templatethatisincluded.YouhavetouseatleastthreehexagonscrewsM6x25(e.g.onmetalground).

♦ Beforeyouconnecttheoutletofthedriveunittothelubricanttube,youhavetomakesurethatthe

lubricationpointsandthecompletelubricanttubeispre-lubricatedwiththesamelubricantthatiscontained

inthePROLCunit.Forthat,perma-tecoffersa400glubricationcartridgeformanually-operatedgrease

presseswiththerequestedlubricant.

♦ Connectthelubricanttube(connectionG3/8)totheoutletofthedriveunitandinstallthetubecorrectly

betweentheoutletandthelubricationpoint.Thelubricanttubemustnotbelongerthanvemeters.

Make sure that you assemble the connections and lubricant tubes correctly and tightly to avoid

possible leakage.

141.5

45

gure3

2hexheadbolts

M6x16,maximum

torque3Nm(supplied

forattachingthe

permaPROtothe

mountingdevice)

Hexagonscrews

M6x25

(forwallmounting

onmetal)

2hexagonscrews

M6x25

(forwallmounting

onmetal)

113

Loading...

Loading...