permaPROC -11-

%Vol.

LC 500

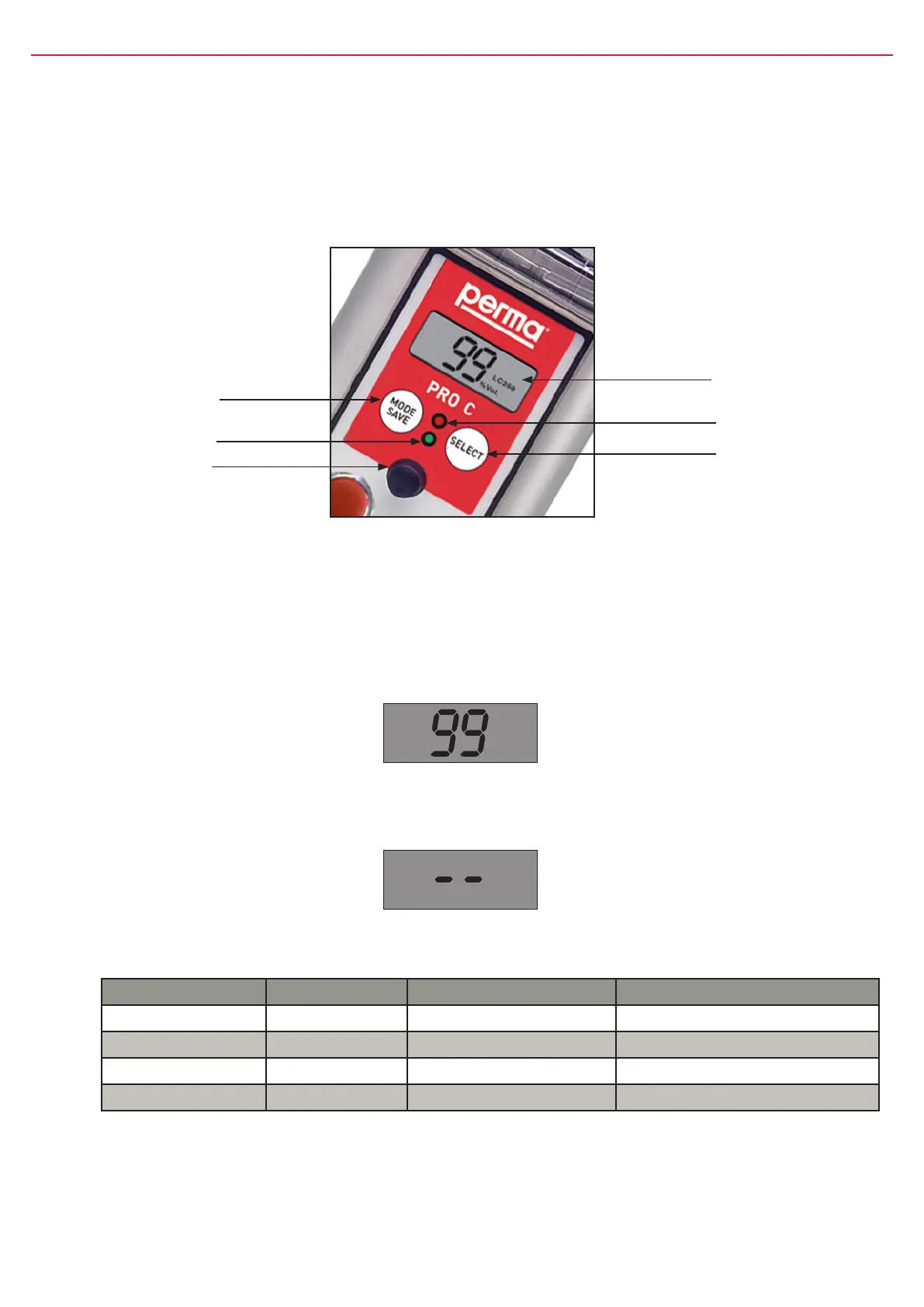

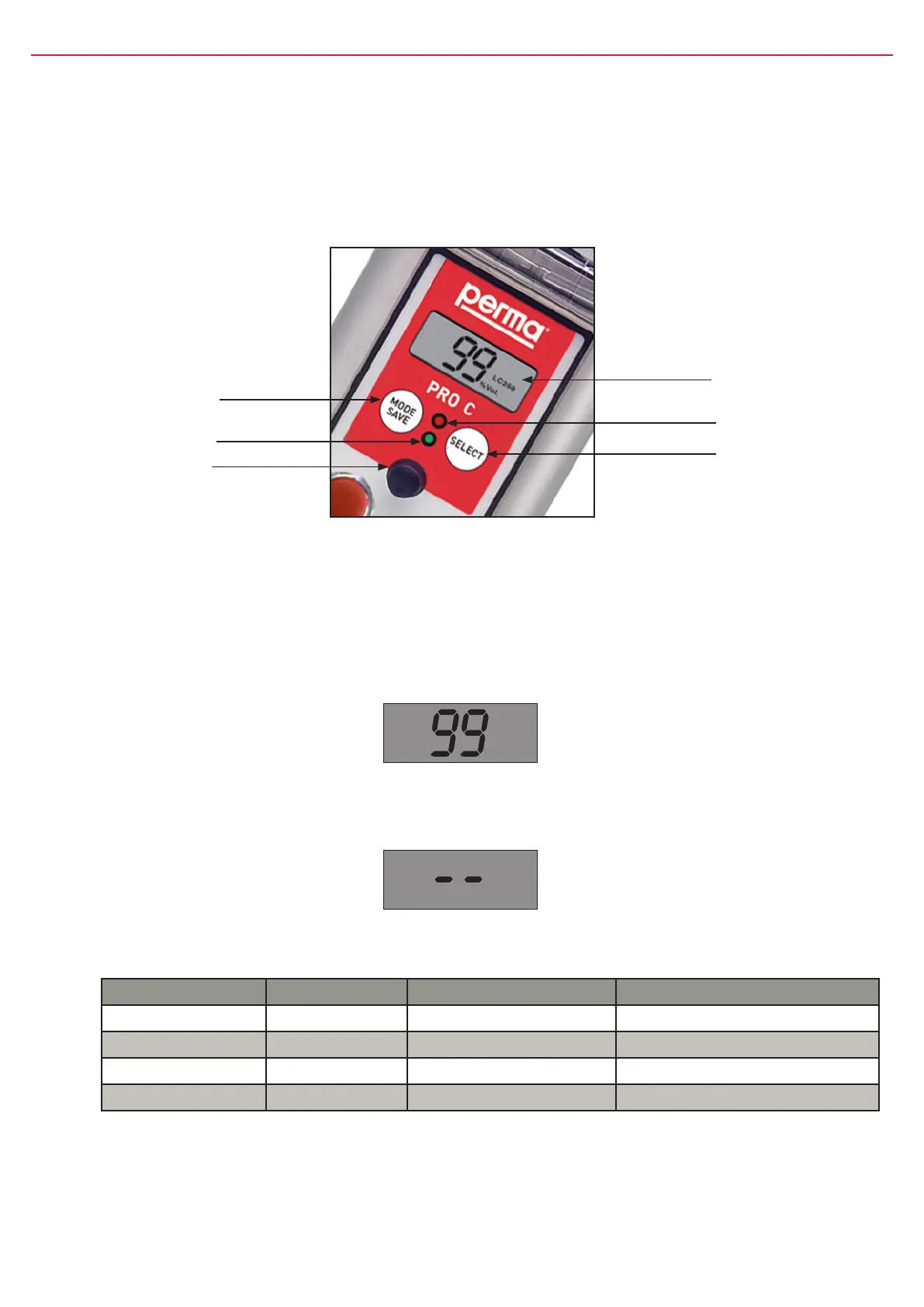

5. Display and Control Elements of the Lubrication System

5.1 Display Elements

TheoperatingstatusofthelubricatorcanbedeterminedviathegreenortheredLEDandviathedisplayatthe

controlunit(refertogure8)ofthepermaPROC.

ThepermaPROCoffersamenu-guidedsetting.Changesofthesettingsareshownonthedisplay.Error

messages,e.g.incasethepressureinthelubricanttubegetstoohigh,arealsoindicatedonthedisplay.

5.2 Function Indication on the Display

ThedisplayislocatedonthecontrolunitofthepermaPROC(refertogure8,chapter5.1).

Thedisplayshowssettings,operatingconditionsanderrormessagesofthelubricator.

Incaseofanerrorfreeoperationofthelubricationsystem,thedisplayshowstheremainingvolumeofthe

mountedPROLCunitinpercentvolume(%Vol.).Figure9showsanexampleofthedisplayedinformation

ifthePROLCunit500isnewandfull.

gure8

MODE

SAVE

push-button

LCD

redLED

SELECT

push-button

greenLED

Connectorfor

distributorMP-6

The display cannot be switched off by the operator. If the lubrication system is switched off, the display

will always show two lines (see gure 10 below).

gure9

gure10

5.3 Function Indication via the LEDs

LED Signal Signal Length Explanation

green ash every10seconds operation(OK)

red ash every3seconds error/malfunction

greenandred ash every3seconds PROLCunitempty

green light permanently Lubricatorisdischarging

chart3

5.4 Function Indication via the Connected Control System

Theconnectedcontrolsystemofyourequipmentcanonlyindicatethatthelubricatorisworking,orthatthereis

amalfunction.IfthepermaPROCisworking,thecontrolsystemreceivesa“High”signalandforamalfunctiona

“Low”signal.

Loading...

Loading...