Mixing Pump PFT G4

Maintenance

2007-09-05 67

Pos: 8.27 /KN2006-Pr ojekte/Knauf/W artung/Mischpumpe PFT G4/1.1. 1 Drücke und Einstell werte prüfen @ 36\mod_11773 48092466_293361. doc @ 446098

8.4.5 Check pressure and set values

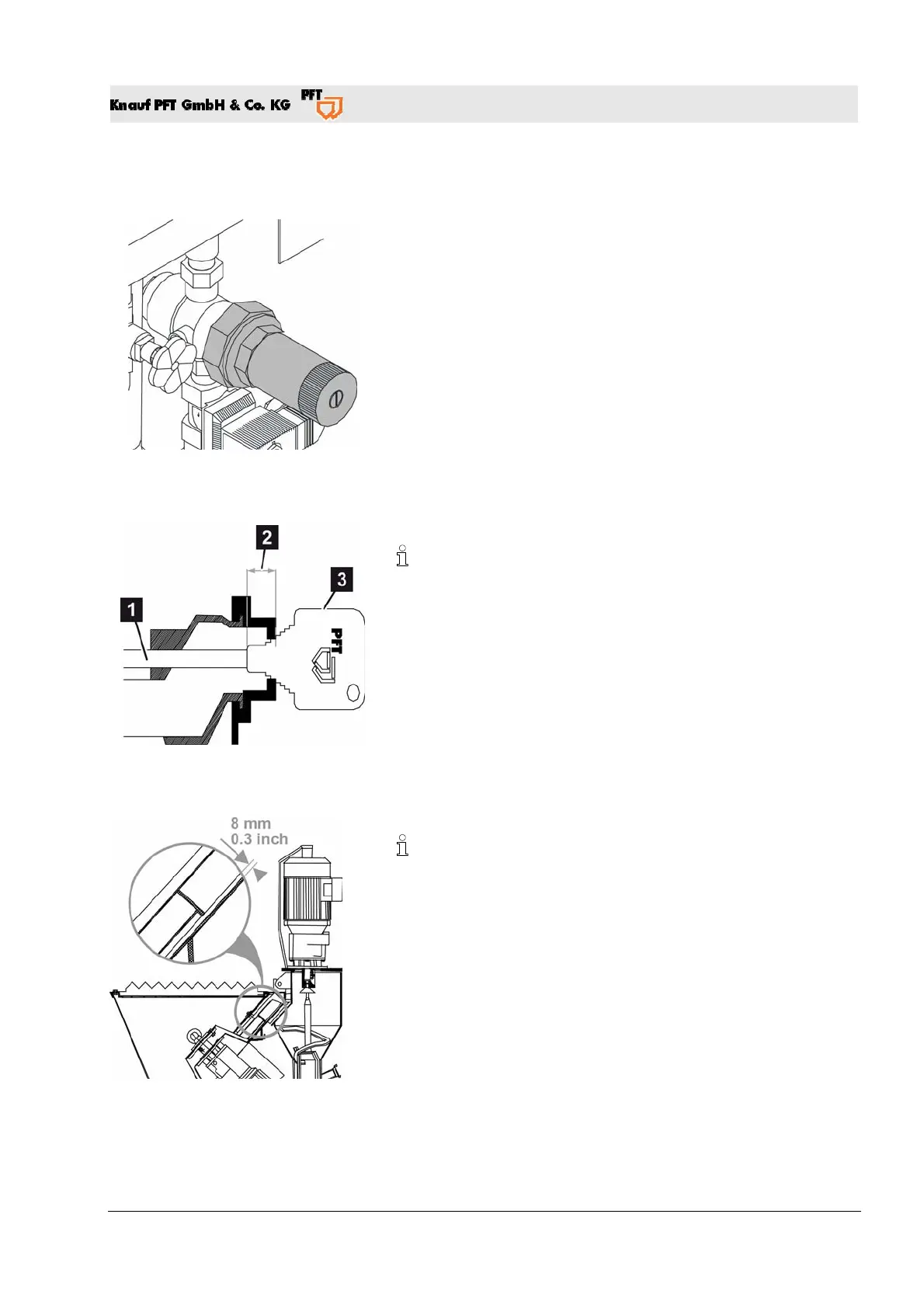

Pressure reducer valve

Fig. 70: Pressure reducer valve

Adjust a pressure of 1.9 bar (27.6 psi) at maximum passage on

the pressure reducer valve (Fig. 70).

Adjust the air nozzle pipe clearance

Fig. 71: Air nozzle pipe clearance

Adjust the air nozzle pipe (Fig. 71/2) clearance with the supplied

gauge (

Fig. 71/3).

The distance between the air nozzle pipe and the plaster nozzle

must correspond to the hole diameter of the plaster nozzle; for

example: 14 mm (0.55 inch) fine plaster nozzle = distance of

14 mm (0.55 inch).

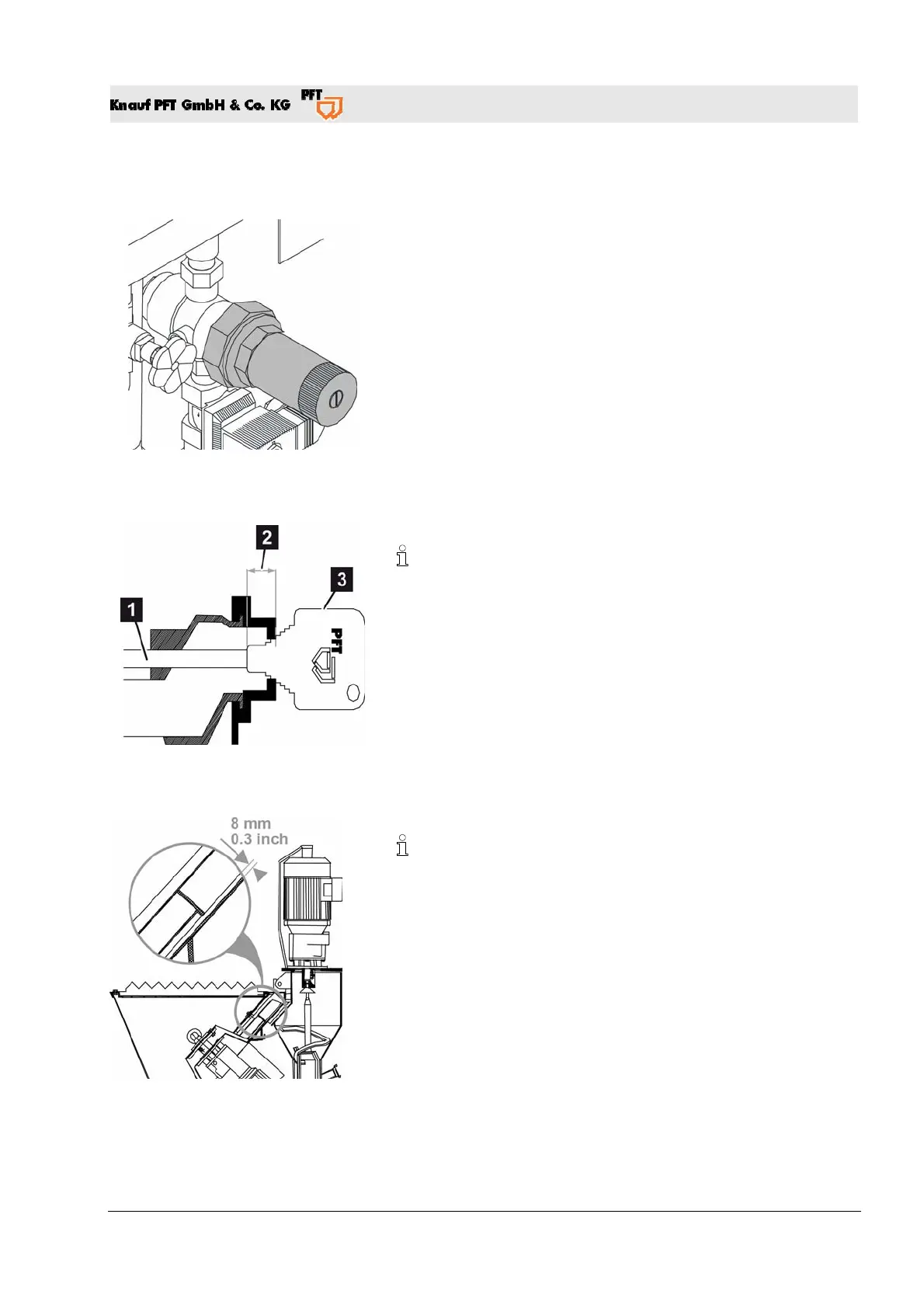

Cellular wheel

Fig. 72: Cellular wheel

Distance from cellular wheel to hopper floor (Fig. 72):

Factory set at approximately 8 mm (0.3 inch).

Rule of thumb: 1.5 times the diameter of the largest grain of

factory dry-mix mortar. If needed the cellular wheel spacer disk

(to be order under the item no. 20 10 19 00) can be installed for

coarse grain plaster.

Pos: 8.28 /KN2006-SM/nL---------- Abschnittsende ---------- @ 8\mod_1141997892953_0.doc @ 293763

Loading...

Loading...