Mixing Pump PFT G4

Appendix

2007-09-05 95

Pos: 11.3 /KN2006-SM/nL---------- Abschnittsende ---------- @ 8\mod_1141997892953_0.doc @ 293763

Pos: 11.4 /KN2006-Pr ojekte/Knauf/Anha ng/Mischpumpe PFT G4/1.1 Checkliste für jährlic he Sachkundigen-Pr üfung @ 13\mod_11526998 23584_293361.doc @ 29886 8

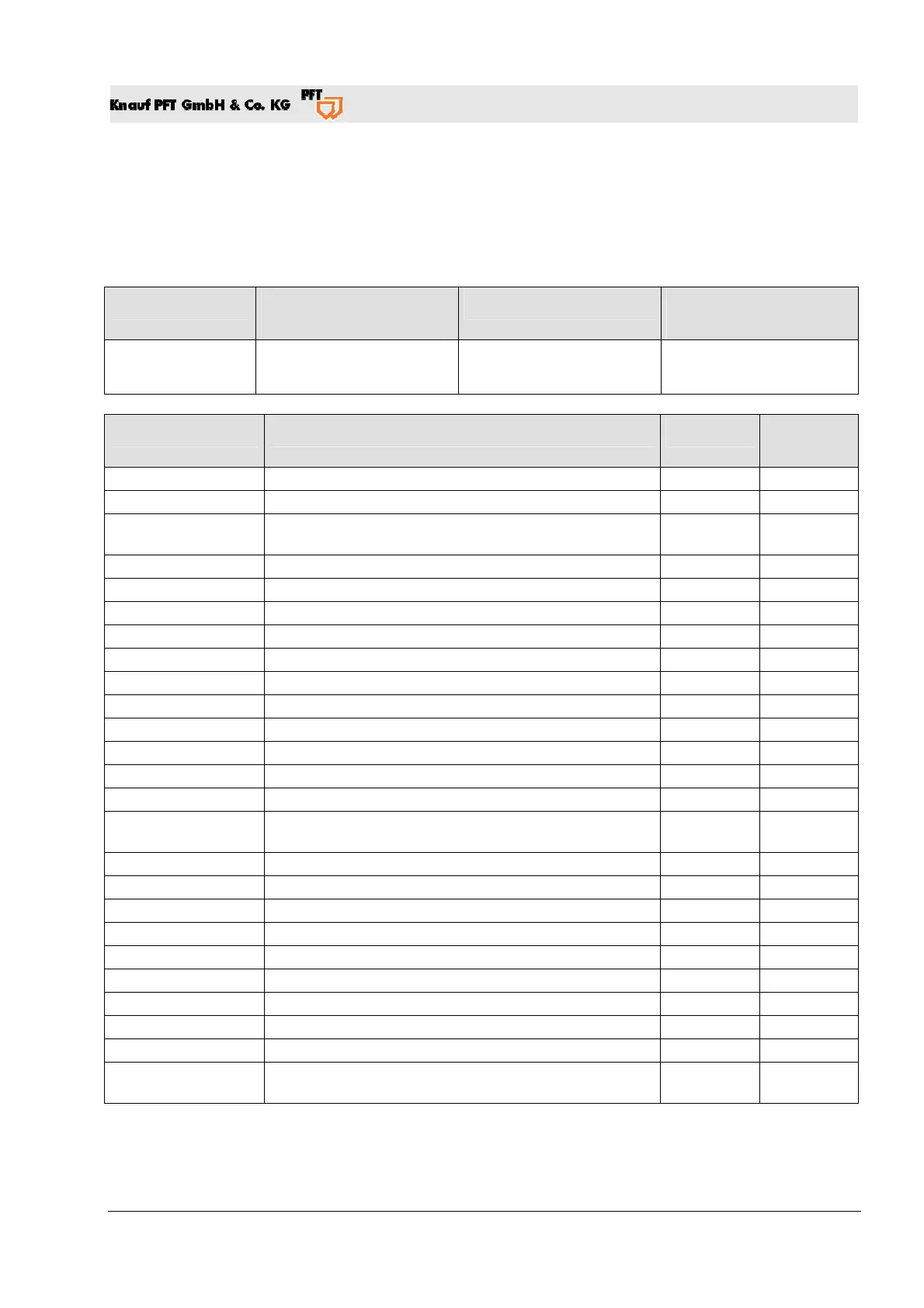

11.2 Check list for annual expert inspection (copy template)

The expert inspection must be executed once a year in accordance with applicable rules and regulations.

A test badge will be affixed to the machine and the control panel as verification of this inspection.

This inspection log must be shown on request.

Inspection date: Inspector:

Signature: Serial identification

number:

Part Test characteristic In order Fix/replace

Material container Check all weld seams.

Material container Destruction due to corrosion or deformation?

Mixing zone Wear on the pipe wall? Minimum wall thickness to be

1.5 mm (0,6 inches).

Mixing helix Wear inspection of the wedge profile in the mixing area.

Mixing helix Wear inspection of the pump driver.

Safety grille Is the safety grille still level?

Limit switch tilt flange Check limit switch for function.

Limit switch tilt flange Check feed line to the limit switch for damage.

Chassis Check all weld seams.

Chassis Check all threaded connections for firm fit.

Chassis Check for deformation. Stability must be ensured.

Castors Do the castors move freely?

Water flow meter Is the view glass still clear and transparent and sealed?

Solenoid valve Function test

Pressure reducer

valve

Function test, check setting 1.9 bar (27.6 psi)

Control panel Visual inspection for apparent defects

Control panel Function test

Control panel Are all stickers in legible condition?

Control panel Measurement of insulation

Control panel Function test of all protective switches.

Control panel Function test of all indicator lights.

Control panel Check all cable connections for firm seat.

Type plate Present and legible

Operating Manual Present

Mortar pressure

manometer

Function test.

===== Ende der Stücklist e =====

Loading...

Loading...