Mixing Pump PFT G4

Maintenance

68 2007-09-05

Pos: 8.29 /KN2006-Pr ojekte/Knauf/W artung/Mischpumpe PF T G4/1.1.1 Kontrollieren d es Förder- und Rückstaudr uckes @ 13\mod_1152625868 222_293361.doc @ 298847

8.4.6 Check delivery pressure and back pressure

To be performed by the operator.

Special tools required:

z PFT pressure tester with coupling and drain cock

(to be order under the item no. 20 21 68 10)

Delivery pressure and back pressure can be checked to determine

whether the pump is damaged and therefore does not supply the

required capacity. If the values specified here are not reached then

the pump must be replaced.

For a pump with clamp clip (optional) it may be sufficient to

retighten the clamp clip.

If the stator or rotor have been newly inserted then an initial

spray process must be executed before the test. Stator and

rotor must first run in.

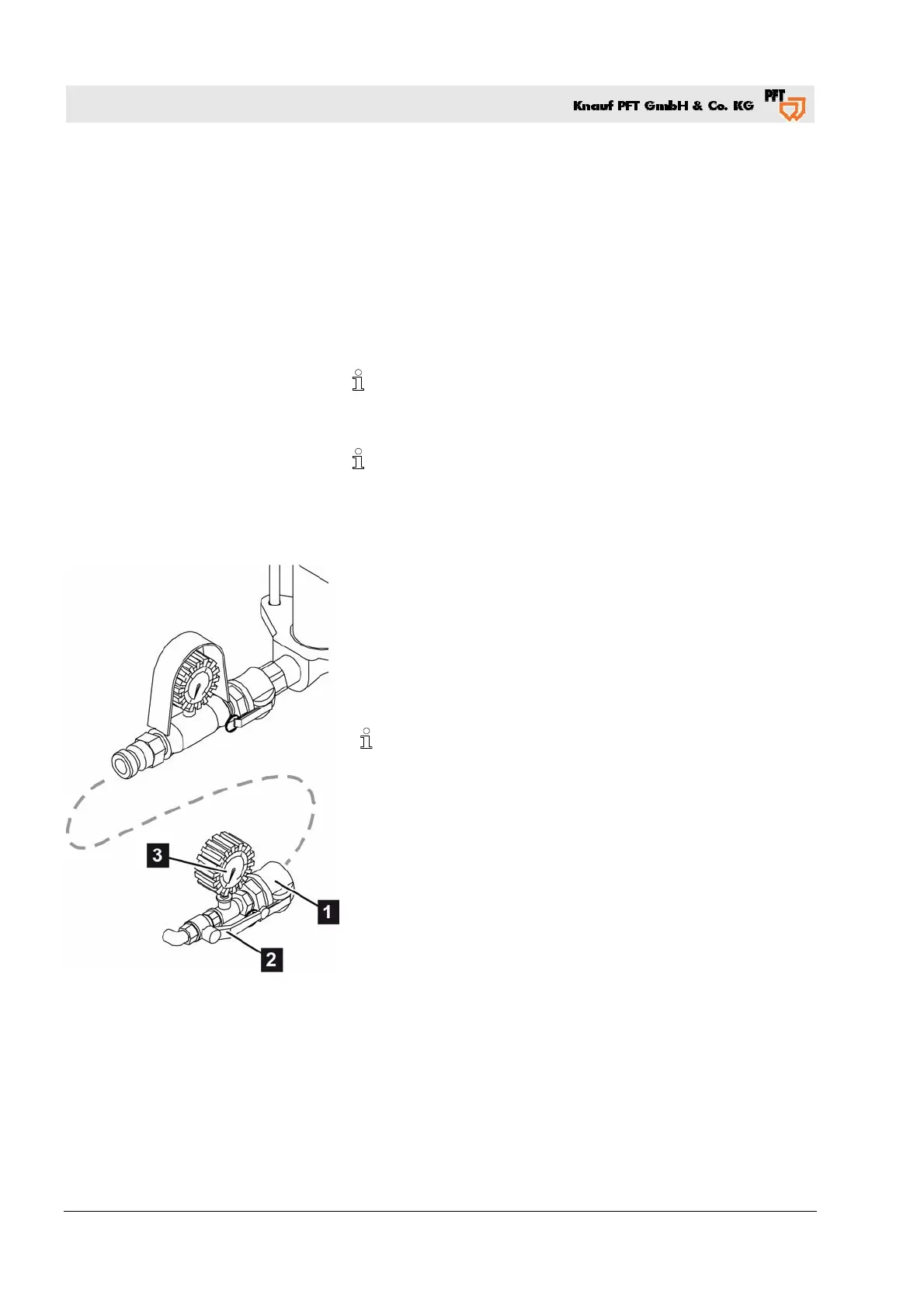

Fig. 73: Coupling the PFT pressure tester

1. Be sure that power and water are connected.

(If not, see chapter "Preparation" in this Operating Manual).

2. Connect 10 m (33 ft) mortar hose.

3. Couple the PFT pressure tester (

Fig. 73/1) to the end of the

mortar pressure hose.

4. Open the drain cock (

Fig. 73/2) on the PFT pressure tester.

Do not introduce any mortar into the system for the test. The

test is executed exclusively with water. Ensure that mortar

couplings are correctly connected.

5. Switch on the machine and let the water run until it escapes at

the PFT pressure tester (vent the mortar hose).

6. Close the drain cock (

Fig. 73/2) on the PFT pressure tester.

The pump will now build up pressure against the closed drain

cock on the PFT pressure tester.

Let the pump run until the pressure no longer increases.

7. Check the delivery pressure on the manometer (

Fig. 73/3) of

the PFT pressure tester. It should show approximately 30 bar

(435 psi)!

Loading...

Loading...