43

The machine must always have the electrodes aligned. Improper

alignment of the electrodes can lead to poor welds that will not pass

OEM requirements.

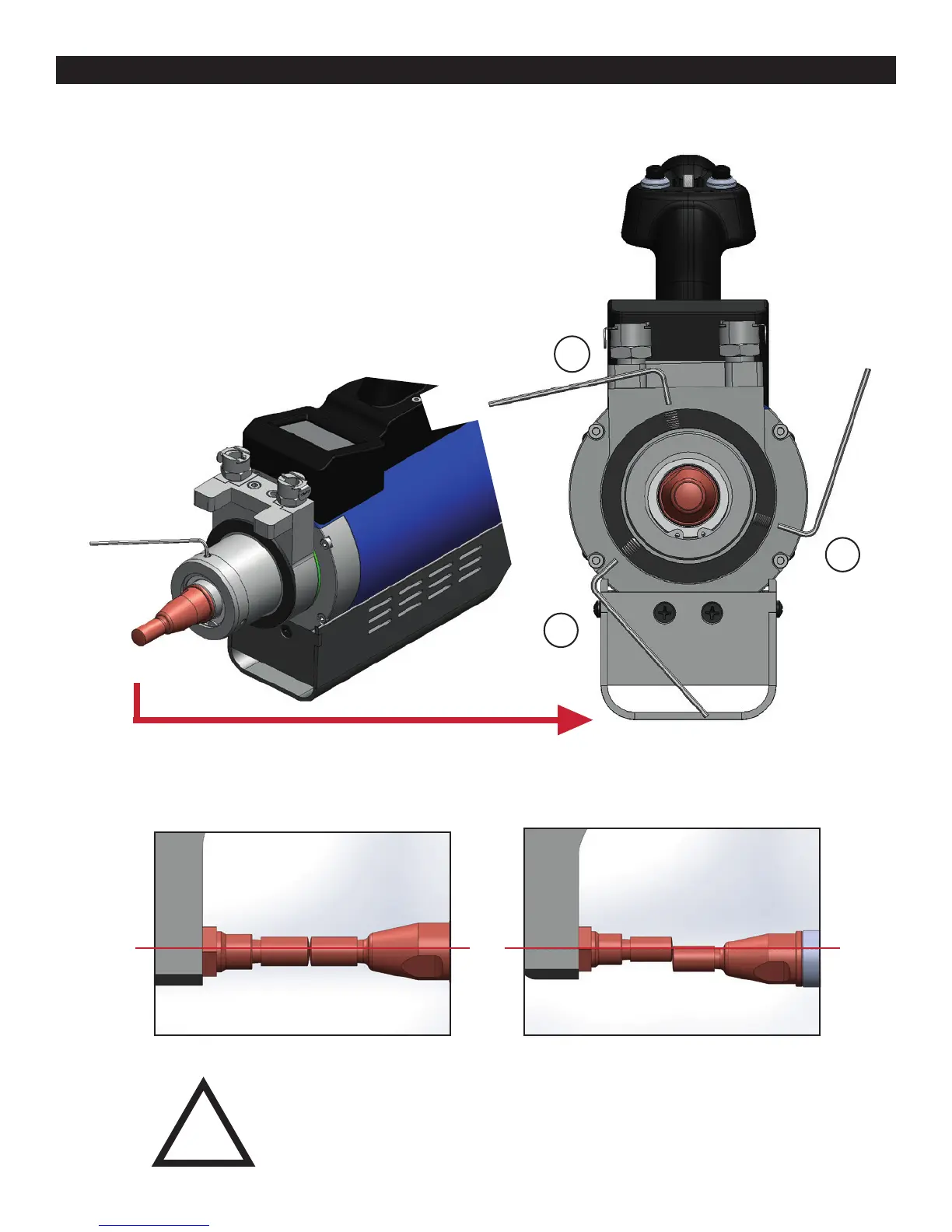

To adjust the electrode on the machine, use the set screws to set

alignment (Figure 1). Use an Allen Wrench to make slight adjustments

to the set screws. Ex: to move electrode down, loosen screw (C) and

tighten screws (A and B).

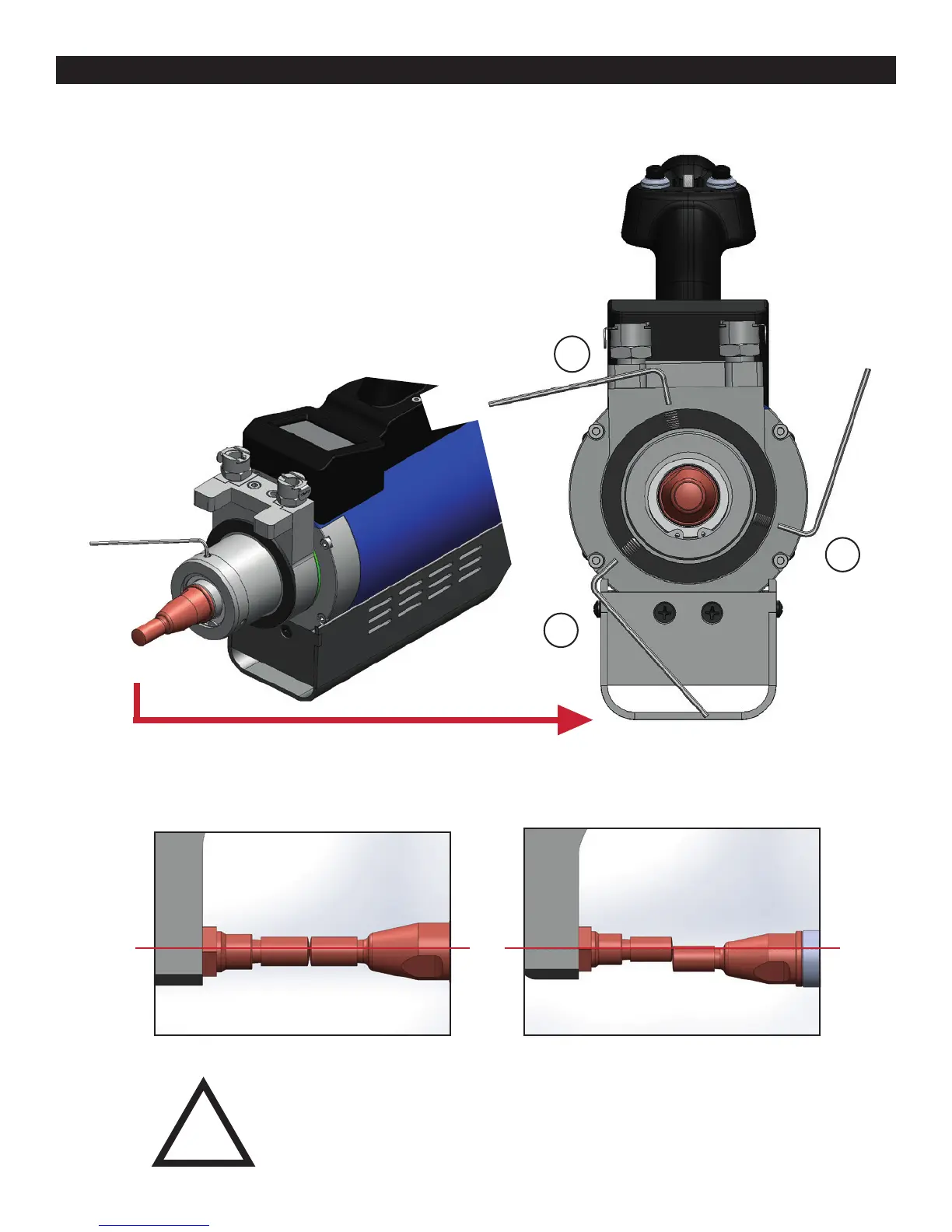

Use an extension arm to test the alignment. Once

the electrode in the gun is evenly aligned with the

extension arm electrode, tighten down the arm and

recalibrate the weld gun.

CORRECT WRONG

IMPORTANT! Proper electrode alignment is critical to weld integrity.

IMPORTANT! Toujours maintenir l’alignement des électrodes appro-priées. Ne

pas le faire peut conduire aux soudures faibles de qualité inférieure!

!

A

B

C

Once you have the electrode alignment correct, it should look like the image below on the left (Figure 8.2). If it

is not a straight alignment, like the image below on the right (Figure 8.3), it will lead to poor and weak welds.

8.0 Electrode Alignment, Removal & Maintenance

8.0 Electrode Alignment, Removal & Maintenance

Figure 8.1

Figure 8.2 Figure 8.3

Loading...

Loading...