5

2.2 Cooling System

IMPORTANT!

shuts off three minutes after the last weld IS completed. Make sure the water lines are connected properly.

coolant it is recommended that a funnel be used to prevent unnecessary spills. When handling antifreeze or 50/50 solution,

avoid contact of with skin, eyes, or mouth. See antifreeze directions for proper handling instructions.

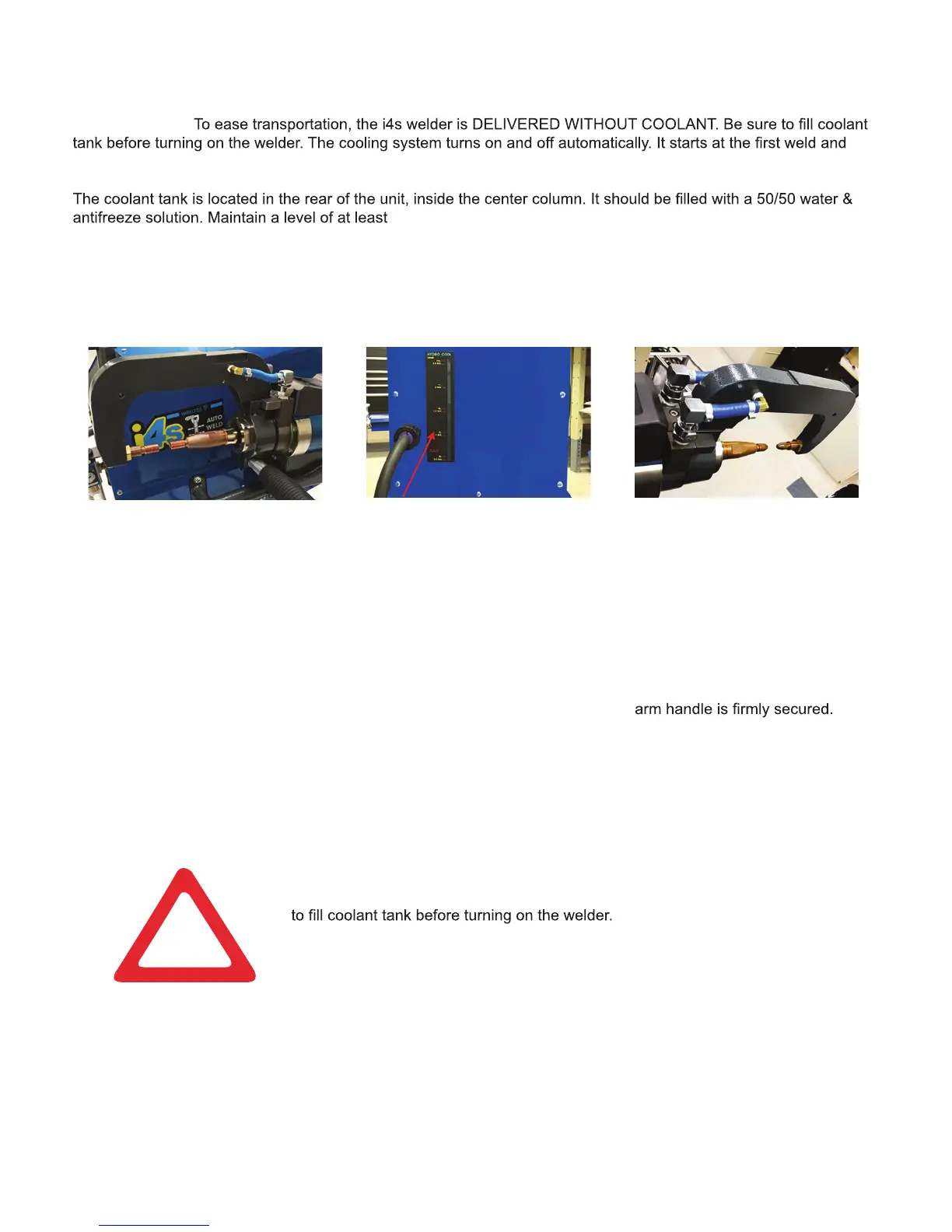

The Coolant Level Indicator

(located on the back, lower left

hand side of the unit), should

be checked regularly to main-

tain 1.5 Gal (6L) minimum in

the tank.

Make sure the water cooling

hoses are securely clipped into

place before welding. Water

will leak if the water feed and

return hoses are not properly

connected (see cooling hose

connections).

Always make sure the welding

arm is installed correctly, and the

The i4s is equipped with a closed

loop cooling system, 2.5 Gal

(10L) tank, radiator with high

powered fan cooling all the way

to the tip of the electrodes.

IMPORTANT! Make sure the water cooling hoses are securely clipped into place

before welding.

IMPORTANT! Turn off the power to the water pump before disconnecting water

hoses from the weld gun.

IMPORTANT! The i4s welder comes without coolant to ease transportation, be sure

IMPORTANT! If the thermal breaker has switched off the welder, please contact Pro

Spot’s authorized service personnel.

IMPORTANT! N’éteignez pas le soudeur pendant que le système de refroidisse-

ment est activé!

IMPORTANT! Si le disjoncteur thermique a éteint le soudeur, s’il vousplaît contac-

tez personnel de service autorisé Pro Spot.

!

2.2 Cooling System

1.5 Gal (6L) of 50/50 solution at all times and do not overfill. When filling

Loading...

Loading...