043

STRUCTURE AND CHASSIS

Torque

The best way to measure torque applied to wheel nuts is to use a torque wrench.

Wheel nuts and bolts must always be tightened at the correct torque.

Otherwise, wheels may come off the axle if the nuts loosen or the stud

bolt breaks. Always use bolts and nuts with the same conical angle as

the rim holes (normally between 60° and 90°). Follow these steps to

tighten the wheel nuts.

Do not tow the trailer with missing nuts, defective wheel bolts, or wheels

incompatible withthe manufacturer. Under- or over-tightening of wheel

bolts may cause the wheel to separate from the axleand result in

physical damage, serious injury, or even death.

WARNING

1. Start tightening the nuts and bolts by hand to avoid cross-threading.

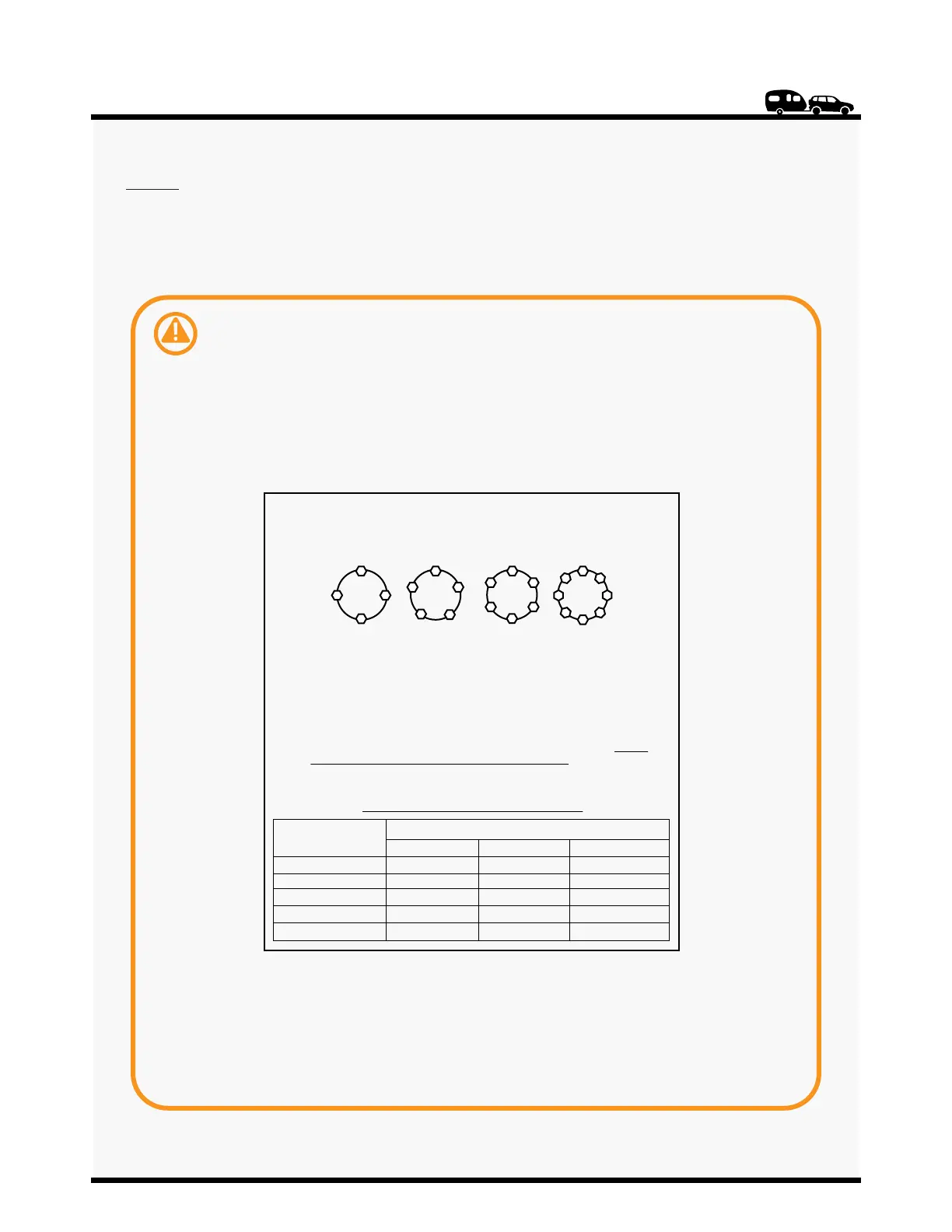

2. Tighten them in the order shown below:

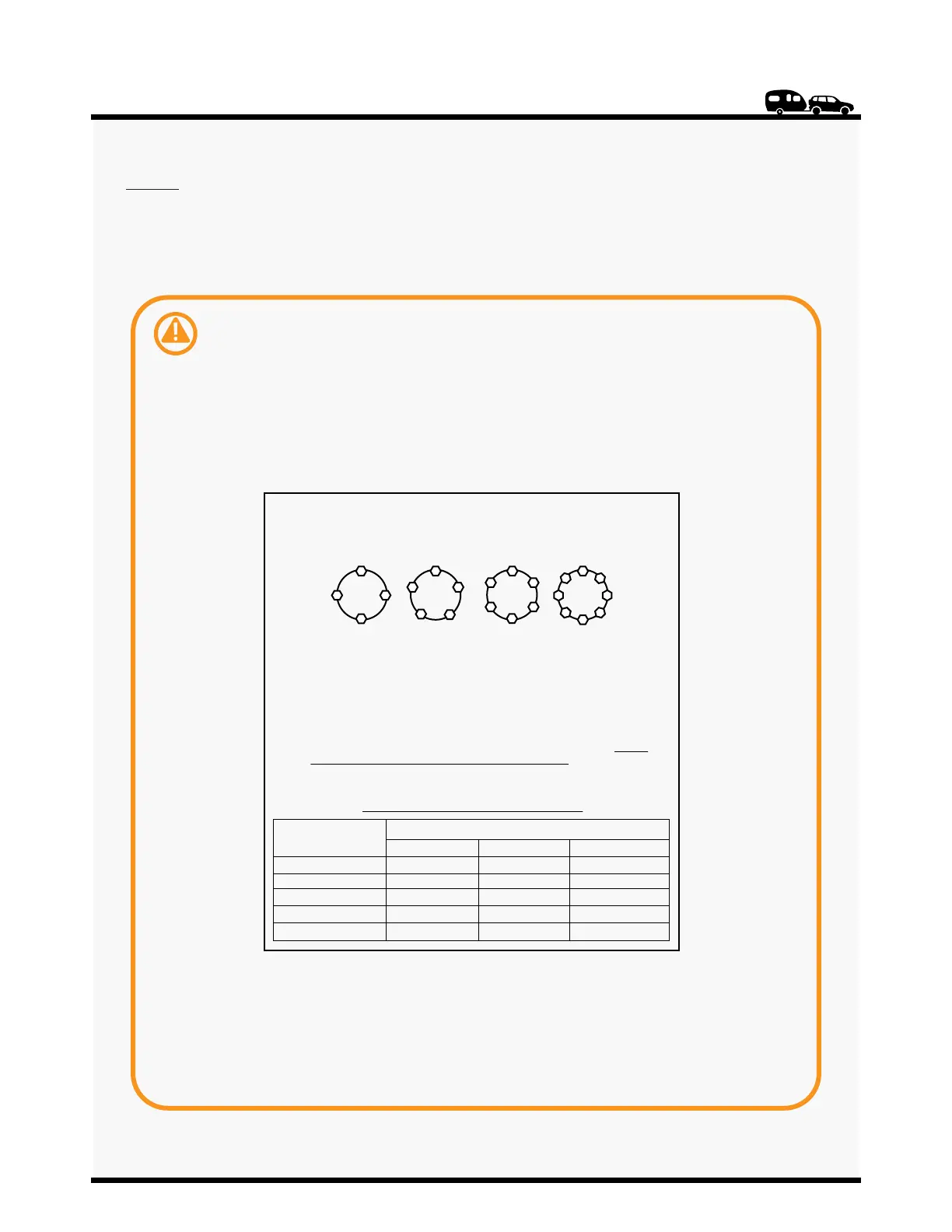

3. Torque tightening is done in stages. Following the order indicated

above, tighten the bolts progressively until your have reached the

required torque, as shown in point 4.

4. You must tighten the wheels with the correct torque each time you

place a wheel on an axle. Check the wheel nut torque after 15, 40

and 80 km on the road, and periodically after that.

Wheel torque setting parameters

1

1 1 1

2

2

2 2

3

3

3

3

4

4

4

4

5

5

5

6

6

7

8

Wheel diameter

12’’

13’’

14’’

15’’

16’’

20 - 25

20 - 25

20 - 25

20 - 25

20 - 25

35 - 40

35 - 40

50 - 60

50 - 60

50 - 60

50 - 75

50 - 75

90 - 120

90 - 120

90 - 120

Torque tightening stages

1

st

stage 2

nd

stage 3

rd

stage

4

studs

5

studs

6

studs

8

studs

43

Loading...

Loading...