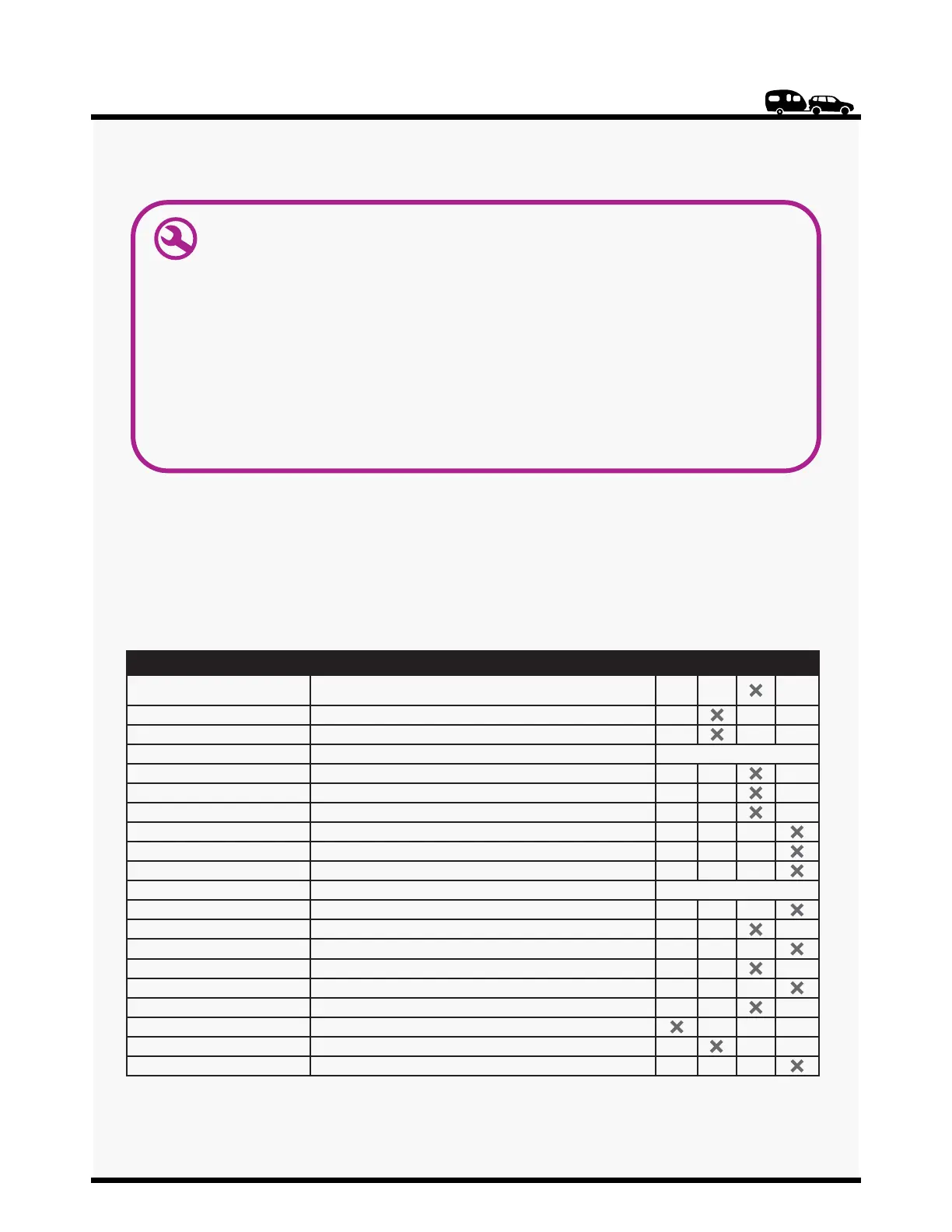

STRUCTURE AND CHASSIS

Bearings and

housing

Wheel nuts and bolts

Check for rust, clean and grease (100 g per wheel).

Readjust bearing nut.

Tighten to required torque.

Brake adjustment

Adjust to specifications.

Brake magnets Inspect for wear and current draw.

Brake linings Inspect for wear and contamination.

Brake modulator Check intensity and modulation.

Brake cylinders Check for leaks or seizure.

Brake lines Check for cracking, leaks or kinks.

Trailer brake cables

Check for stripped frayed insulation.

Parking brake

Check load status and switch.

Hub / drum Check for abnormal wear and scoring.

Seals Check and replace as required.

Springs Check for wear and sag.

Suspension accessories Check for twisted, loose or worn bolts.

Spring mount Check welds.

Wheels Check for cracks, dents, or deformations.

Tire pressure

Inflate to manufacturer’s specifications.

Tire condition

Check for cuts, wear or bulging.

Immersion in water Fill cavity completely.

Brake Check condition and operation.

Parts Actions required

Each

week

3 months

4500km

6 months

9000km

12 months

18000km

EACH USE

EACH USE

* It is important to comply with all actions required for maintenance of your trailer, as indicated in the maintenance calendar above. Failure to do so may void the Frameco warranty.

044

Maintenance calendar recommended by the axle, suspension, brake, and tire

manufacturers

See the calendar below and follow each manufacturer’s recommendations.

When the trailer is in storage or not in use, ensure that tires are properly

inflated to the pressure recommended by the tire manufacturer and

shade them from direct sunlight to prevent cracking.

Place protection from the ground such as a black garbage bag, piece of

carpet or plywood under the tires to protect them from any potential

chemical spills.

MAINTENANCE

44

Loading...

Loading...