Configuration as a Modbus Slave MVI56E-MCM ♦ ControlLogix Platform

User Manual Modbus Communication Module

Page 60 of 209 ProSoft Technology, Inc.

Note: You should only use Pass-Through mode when there is no other option, as there is a

drawback to this mode that is not present in the standard mode.

Because the module must wait for the ladder logic to confirm receiving the new data from the

Master, if the Master issues consecutive write commands, the module cannot process the second

write command until it has finished with the first command. This will cause the module to respond

with an error code of 6 (module busy) on the Modbus network.

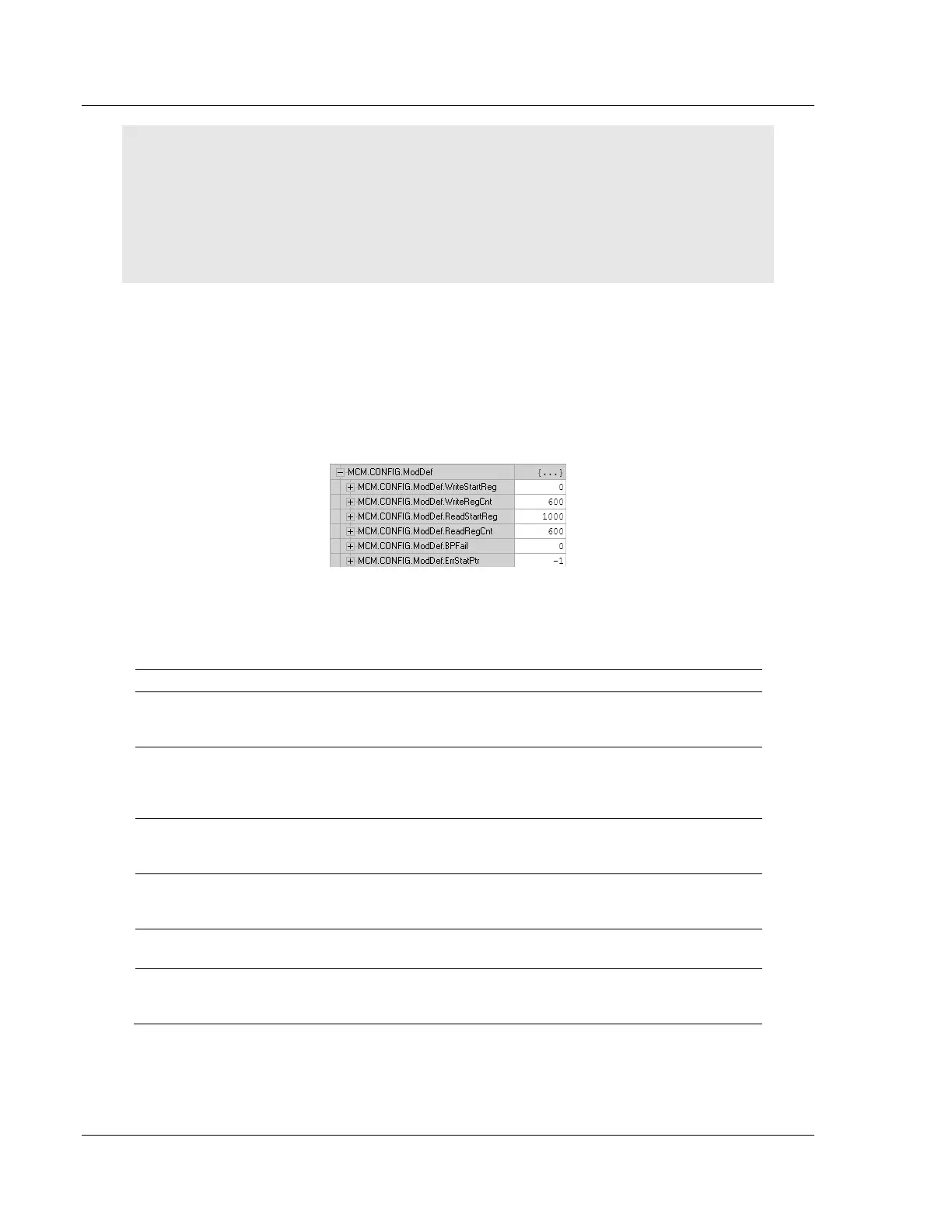

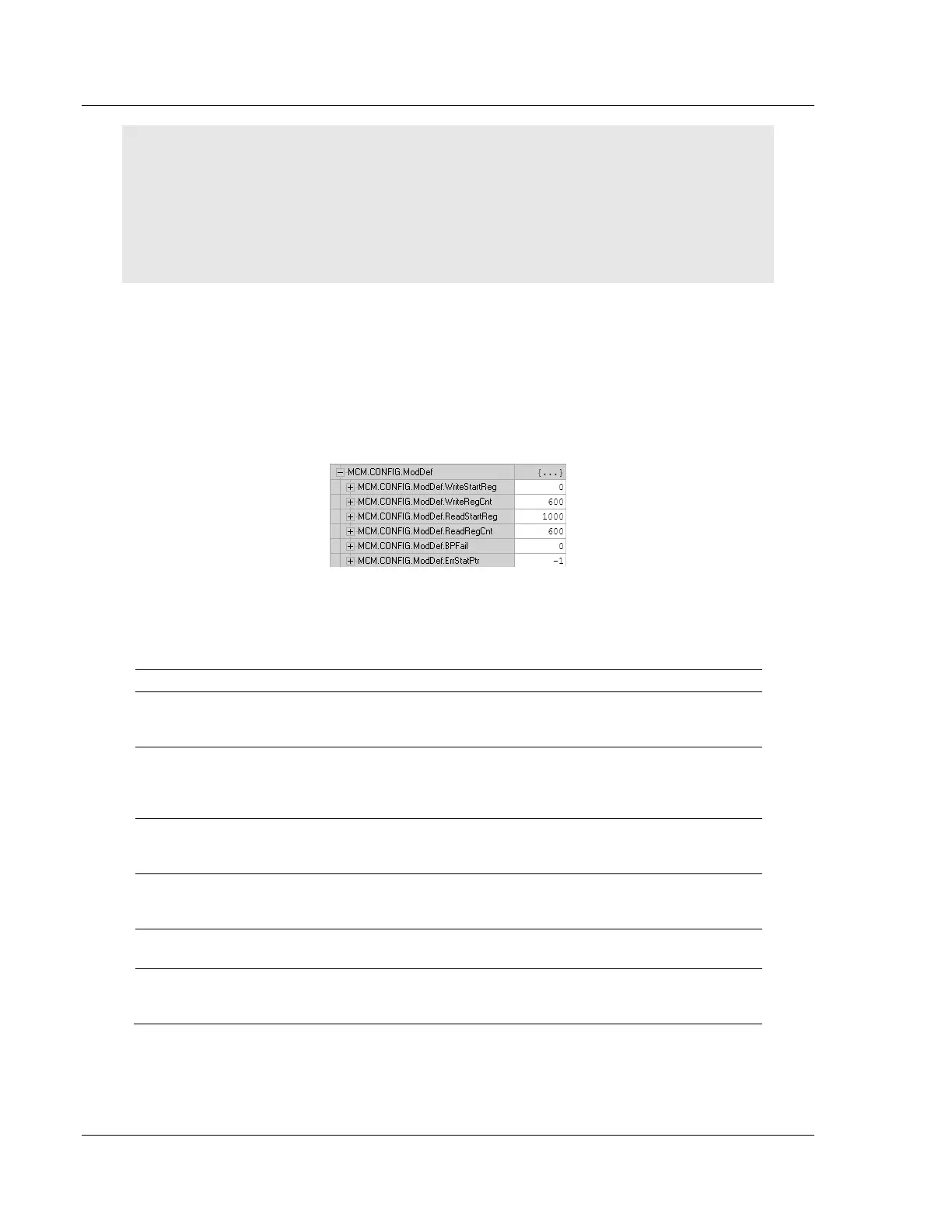

3.2 ModDef Settings

To configure Modbus Slave mode, use the MCM.CONFIG.MODDEF settings.

This section specifies which of the MVI56E-MCM module’s 10,000 registers of

memory to send from the ControlLogix processor to the MVI56E-MCM module

(WriteData) and which registers to send from the MVI56E-MCM module to the

ControlLogix processor (ReadData).

The WRITESTARTREG determines the starting register location for WRITEDATA [0

TO 599] and the WRITEREGCNT determines how many of the 10,000 registers to

use for information to be written out to the module. The sample ladder file will

configure 600 registers for Write Data, labeled MCM.WRITEDATA[0 TO 599].

Determines where in the 10,000 register module memory to place the

data obtained from the ControlLogix processor from the WriteData

tags.

Sets how many registers of data the MVI56E-MCM module will

request from the ControlLogix processor. Because the module pages

data in blocks of 200 words, this number must be evenly divisible by

200.

Determines where in the 10,000 register module memory to begin

obtaining data to present to the ControlLogix processor in the

ReadData tags.

Sets how many registers of data the MVI56E-MCM module will send

to the ControlLogix processor. This value should also be a multiple of

200.

Sets the consecutive number of backplane failures that will cause the

module to stop communications on the Modbus network.

This parameter places the STATUS data into the database of the

module. This information can be read be the Modbus Master to know

the status of the module.

Loading...

Loading...