10 | Gas connection for gas units

84 / 108 80.06.070_iCombiPro-iCombiClassic_IM_en-GB

n

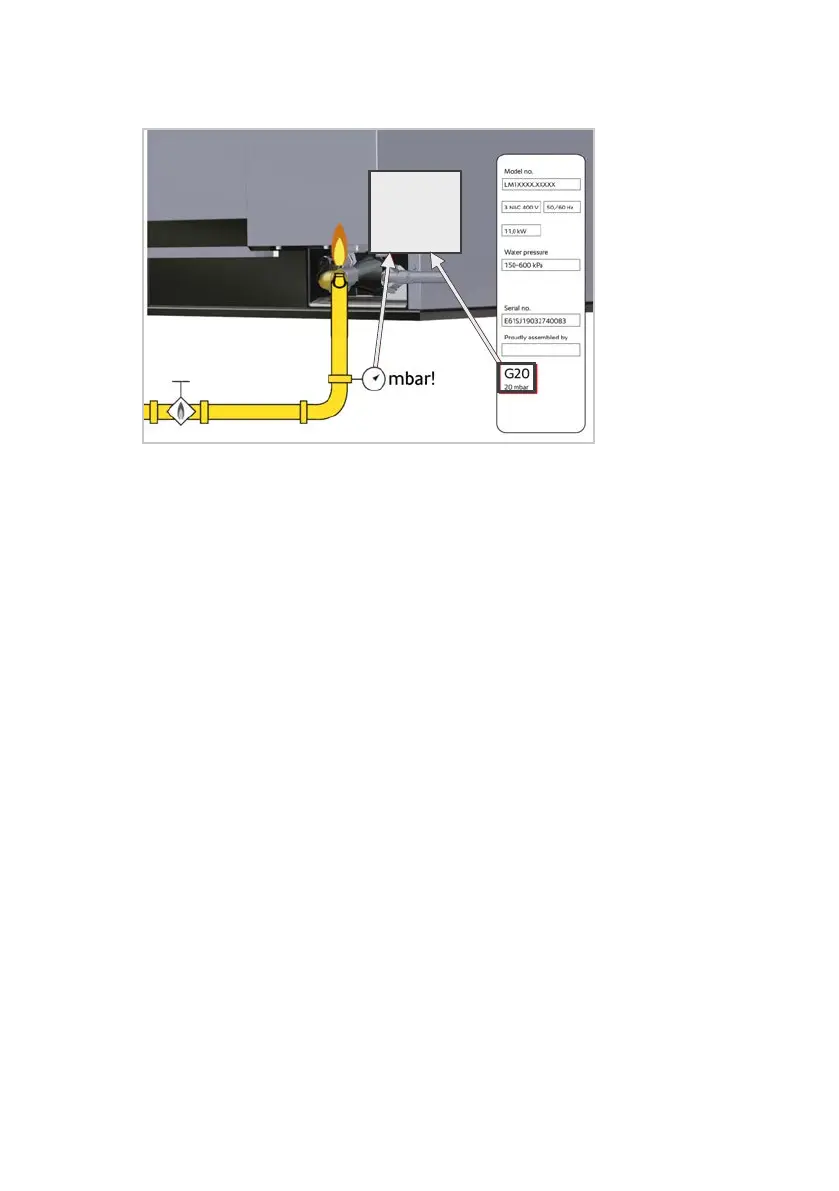

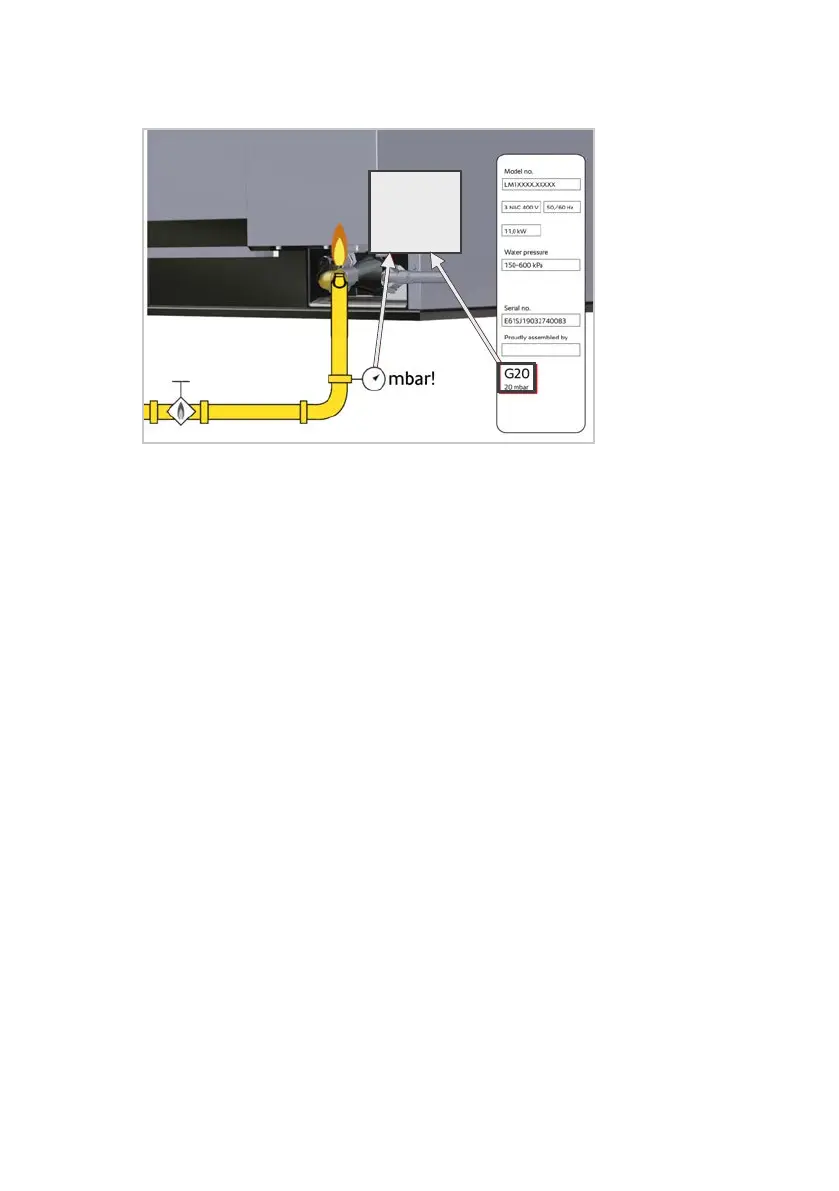

The gas type and the dynamic connection pressure set on the unit must

correspond to those stated on the type plate.

n

If the line pressure deviates from the connection flow pressure of the unit,

contact your gas supply company.

n

Adhere to all local gas company regulations.

Requirements for gas inlet and gas line

n

The exhaust gas analysis may only be carried out by a technician who is

authorised by the manufacturer. The exhaust gas analysis must be carried

out before commissioning.

n

Gas connections must only be set up by locally authorised gas technicians.

n

The gas connection line must be set up in accordance with the rated

thermal load specified on the type plate.

n

Use a suitable gas leak detector to check for leaks in the gas supply and gas

distribution within the unit.

n

The cross-section of the gas line must be designed to the maximum con-

nected output of all loads, at least ¾ inch.

n

A gas shut-off valve must be installed in front of every unit.

n

All on-site connection parts must be tested in accordance with DIN-

DVGW (the local regulations).

The hose for the gas connection must not be longer than 2.0m [78 3/4

inch].

n

It is possible to connect the gas line with a gas socket.

n

A connection with the appropriate counterpart to the ¾inch internal

thread (RP thread) is required to connect the gas line.

n

The unit must be protected against slipping.

Loading...

Loading...