Installation: Installation Preparation 17

INSTALLATION

9. Pull excess slack in hose through clamps (there may be 4” or more), towards the front of the machine. Ensure

the hose does not obstruct tire operation.

FIGURE 14. Drive Motor Hoses with Slack Removed

10. Tighten the hose clamps on the hose in the new position.

11. Retract the axles to the narrowest operation position (typically 120”).

12. Ensure that the hose is not pinched or stretched when extending or retracting the axles. If the hose appears to

be pinched or stretching, loosen clamps and provide more slack to that area.

13. Move the axles out to the widest position before beginning installation.

14. Install one of the provided 3’ nylon hose guard sleeves onto both the left and right wheel drive motor hoses.

Secure the hose guard sleeves to the hoses with the provided cable ties.

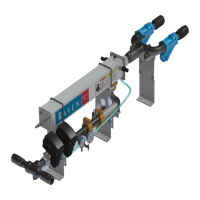

FIGURE 15. Drive Motor Hose Protection

Slack Pulled

Through Clamps

Towards Front Axle

Hose Guard Sleeve

(214-3000-002)

Cable Ties

Loading...

Loading...