TempTracker mod+ Hybrid Installation and Operation Manual 13

HTC# 059105-00D

• The System Output relay will remain active until the System Run-On Delay expires and then it will turn off.

• When Setback is selected in the Startup, a BMS/EMS or external clock can provide a Setback signal using these

input terminals. See "Shutdown/Tstat/Setback Mode" on page 26. No Day/Night Schedule will be available when

Setback is selected from the Shutdown/Tstat/Setback mode in the Startup menu.

• Bring the two wires from the dry contact to the terminals marked SHUTDOWN/TSTAT/SETBACK- 31,32.

• The signal must be a dry contact only. No voltage can be placed across the SHUTDOWN/TSTAT/SETBACK

terminals.

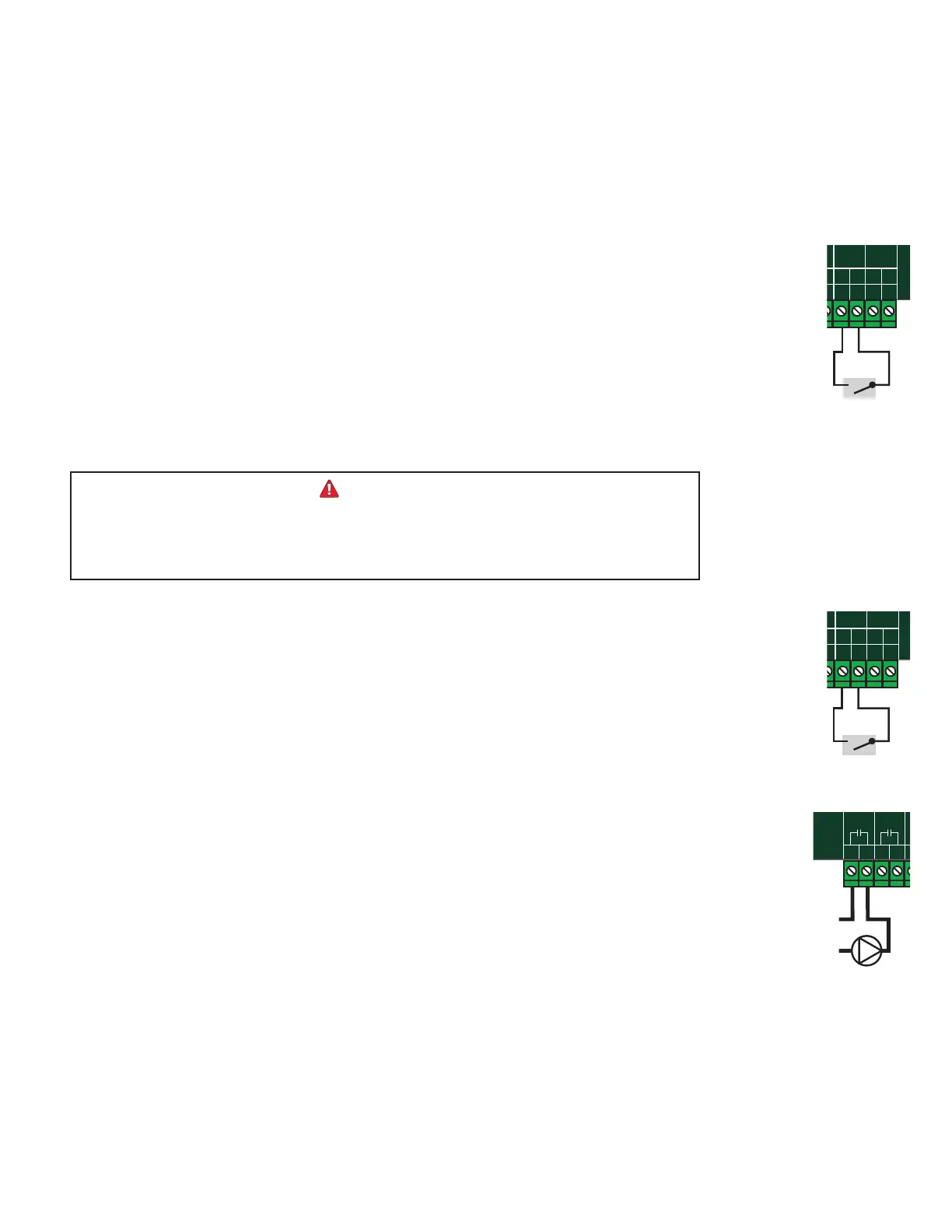

(Terminals 29, 30)

• The Prove feature is provided to check system component operation and must be selected in the Startup Menu

from the Prove/DHW Sharing menu. See "Prove/Indirect Domestic Hot Water (DHW) Priority" on page 25.

• A typical use of this feature is to check for pump ow or combustion air damper status before ring any boiler.

• If the PROVE input is open on a call for heat, the TempTracker mod+ Hybrid will enable only the System Output.

All boiler outputs will be off when the PROVE input is open.

• A factory-installed jumper provides the System Prove signal. Do not remove the jumper unless it will be replaced

by a System Prove signal or these terminals are to be used for DHW call input.

• Bring the two wires from the dry contact to the terminals marked PROVE - 29, 30.

• Prove Input terminals can accept a dry-contact signal only. No voltage can be placed across these terminals.

The PROVE input cannot be used as a safety limit. All equipment must have its own

certied limit and safety controls as required by local codes. If Prove is selected in the

startup menu, no boiler stage will start unless Prove terminals are shorted. DO NOT

remove the PROVE jumper supplied unless replacing it with a Prove signal.

SYSTEM

A

B

C

D

1

2

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

Prove Signal

(Terminals 29, 30)

• DHW can be used to raise system Set Point to the DHW Set Point as well as manage the System Pump according

to the DHW Priority setting. One of the DHW options must be selected from the Prove/DHW Sharing Startup

menu. See "Prove/Indirect Domestic Hot Water (DHW) Priority" on page 25.

• Wire an aquastat or a control to provide dry-contact closure on the DHW Call - 29, 30 terminals.

• Remove the jumper on the DHW terminals for proper operation.

• DHW Call terminals can accept dry contact signals only. No voltage can be placed across these terminals.

SYSTEM

A

B

C

D

1

2

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

Indirect

DHW Signal

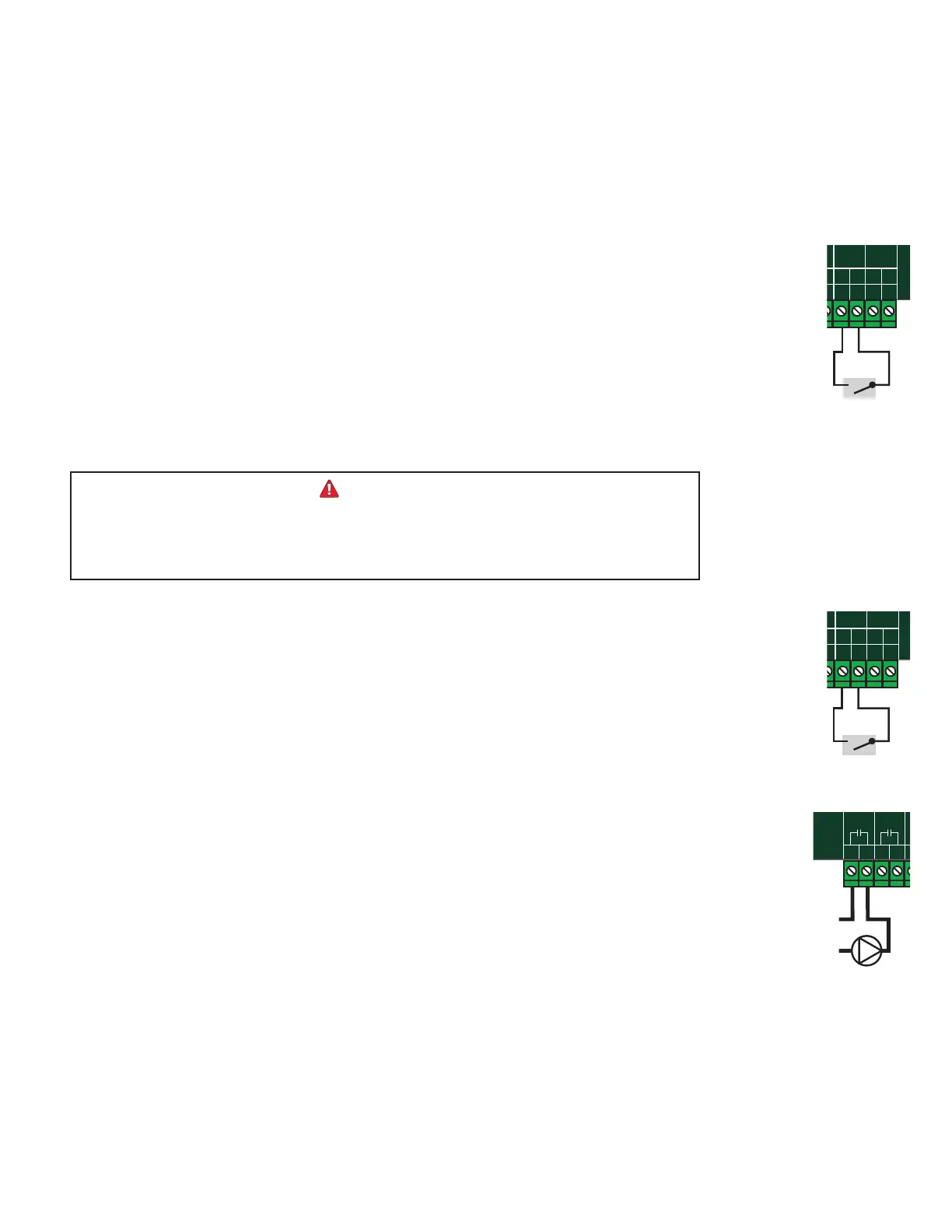

(Terminals 3, 4)

• The SYS output relay will energize and remain constantly energized whenever the outdoor temperature is below

the Outdoor Cutoff.

• When the outdoor temperature rises 2°F above the Outdoor Cutoff, the SYS output will remain energized for the

period set by the System Run-On then de-energize. See "System Run-On" on page 33.

• In addition, the System output will energize during summer DHW calls when DHW No Priority is selected. See

"Prove/Indirect Domestic Hot Water (DHW) Priority" on page 25.

• The SYS output has one Normally Open (N.O.) relay contact rated for (1/8 HP).

• The N.O. contacts are dry contacts only. They do not source any voltage.

• Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

SYSTEM

A

B

C

D

1

2

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

HYBRID

System Pump

or Pump Starter

L

N

Loading...

Loading...