40 Raypak, Inc.

HTC# 059105-00D

The TempTracker mod+ Hybrid display layout reserved the second line for message indications. The following is a list of the most

common Message Display Line information:

• Boost To 170˚F The Boost has started 30 minutes before the Day Schedule setting and the Boost temperature is 170˚F.

See "Boost Mode" on page 26.

• DHW Call (180˚F) There is an indirect DHW call. The TempTracker mod+ Hybrid will raise the system Set Point to the

indicated temperature. DHW increases calculated temperature to the DHW Set Point. See "Indirect

Domestic Hot Water Set Point" on page 26.

• Holding Until 150˚F The Lead boiler is in Last Stage Hold. This example shows that the lead stage will turn off when system

temperature reaches 150˚F. See "Last Stage Hold" on page 34.

• Interface Module Error There is no communication to the BACnet Module Interface while the BACnet Mode is set to Enable.

See "BACnet Mode" on page 27.

• Lag Delay: 123 The lead boiler is at 100% and the remaining purge time to start the lag boiler in seconds is 123. See "Lag

Delay" on page 35.

• Outdoor Cutoff The outdoor temperature is above the Outdoor Cutoff setting. No boilers will be active for heating. See

"Outdoor Cutoff Temperature" on page 32.

• Prove Failure After boilers have run for some time, Prove signal has ended. All boilers set to Auto or Standby will

de-energize. However, the System relay will remain energized. See "Prove/Indirect Domestic Hot Water

(DHW) Priority" on page 25 and "Wiring the Prove" on page 13.

• Purge Delay: 23 A boiler is in purge cycle and the remaining purge time in seconds is 23. See "Purge Delay" on page 33.

• Setback to: 130˚F The Night Schedule or Setback input is active. Current Setback temperature is 130˚F. See "Setback"

on page 33. See "Day/Night Schedules" on page 37.

• Shutdown Active The Shutdown Terminals are Shorted. No boilers will be active. See "Shutdown/Tstat/Setback Mode" on

page 26. Also See "Wiring the Shutdown, Tstat, or Setback" on page 12.

• Summer The control is set to Summer. No heat is active. See "Season" on page 31.

• Switch in: 00:30 The switch from one group to the other will take place after 30 minutes. See "Switch Delay" on page 22.

• System Run-On: 46 The System relay is ON for the System Run-On Delay. This example shows that it will remain in System

Run-On for an additional 46 seconds before turning off. See "System Run-On" on page 33.

• Tstat Call The Tstat Terminals are Shorted. Boilers will be active. See "Shutdown/Tstat/Setback Mode" on page 26.

• Waiting for Prove The System relay is ON and the prove terminals are open before the lead boiler relay can energize. See

"Prove/Indirect Domestic Hot Water (DHW) Priority" on page 25.

Button: STAGE/

The Stage menu provides adjustment for each of the individually boiler operations.

• In most installations, all active boiler adjustments are the same, but each can be congured

differently if desired.

• If the boilers are not set up properly, the TempTracker mod+ Hybrid operation may appear

to be erratic.

• When the STAGE button is depressed, the Boiler A settings menu will be shown.

• Make all the appropriate settings for Boiler A (See below).

• After completing all the settings for Boiler A (See below), you have the option of copying

these settings to all other modulating boilers. Everything but the Mode -- Auto/Standby/

Manual/Off/On -- will be copied.

• Then select the <NextStage> option from the menu to reach the Boiler B settings

menu. Continue until all boilers have been set.

• If an Extension is connected to the TempTracker mod+ Hybrid and the stages have been set

through the Startup menu, then scrolling through stages using the <NextStage> and

<PrevStage> menu options will scroll through the Extension stages as well.

To change the TempTracker mod+ Hybrid settings, the Program/Run Switch must

be set to Program. The switch is located under the Enclosure Wiring Cover for

security. The Enclosure Wiring Cover can be secured using a lock.

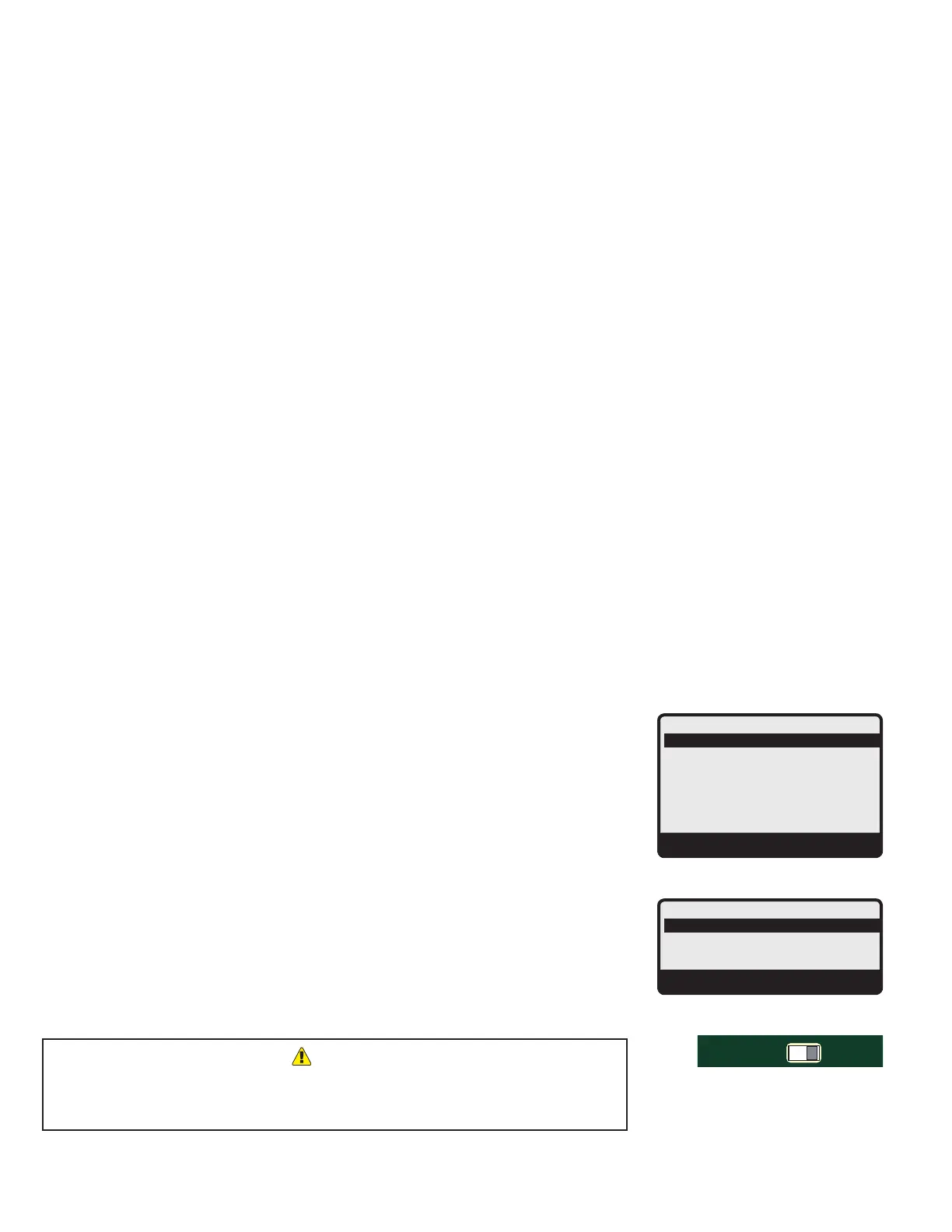

Modulating Boiler Stage Menu

STAGEASETTINGS

Mode Auto

Ignition% 1%

ModStart% 80%

<PrevStage>

<NextStage>

CopySettings

BACK▲▼SELECT

Sequencing Boiler Stage Menu

STAGEASETTINGS

Mode Auto

<PrevStage>

<NextStage>

BACK▲▼SELECT

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

HYBRID

Loading...

Loading...