TempTracker mod+ Hybrid Installation and Operation Manual 51

HTC# 059105-00D

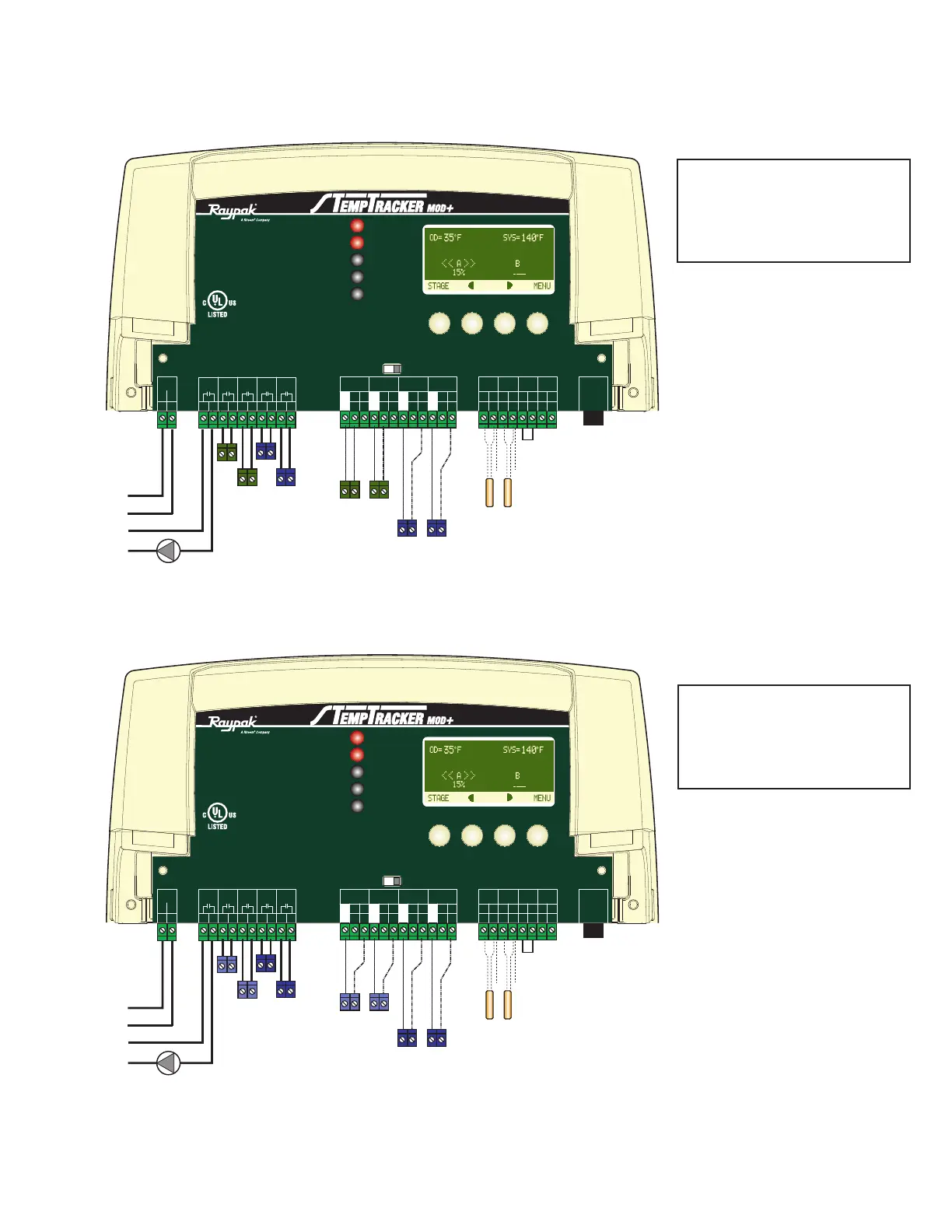

SYSTEM

A

B

C

D

1

2

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

HYBRID

Boiler 1

Boiler 2

Boiler 3

Boiler 4

Boiler 1

Boiler 2

Voltage

Modulating

Signal Outputs

Outdoor Sensor

System Sensor

Prove Jumper

Do Not remove

Shield

Shield

L

N

System Pump

L

N

Modulating

Condensing

Group (Boiler 1 & 2)

{

Staging

Non-Condensing

Group (Boiler 3 & 4)

{

Boiler 1

Boiler 2

Staging Voltage

Signal Outputs

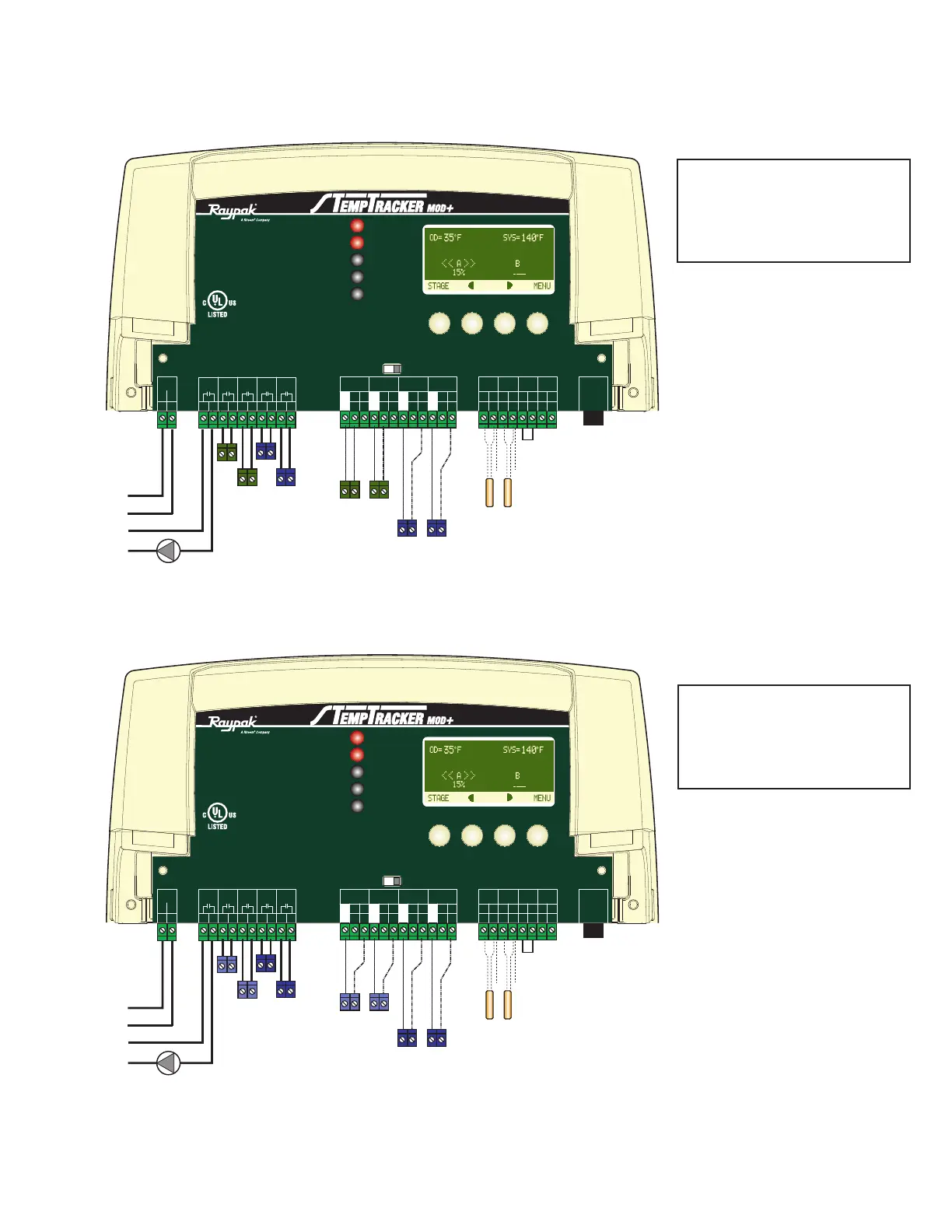

SYSTEM

A

B

C

D

1

2

RUNPROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

HYBRID

Boiler 1

Boiler 2

Boiler 3

Boiler 4

Boiler 1

Boiler 2

4 - 20 mA

Modulating

Signal Outputs

Outdoor Sensor

System Sensor

Prove Jumper

Do Not remove

Shield

Shield

L

N

System Pump

L

N

Modulating

Condensing

Group (Boiler 1 & 2)

{

Staging

Non-Condensing

Group (Boiler 3 & 4)

{

Boiler 1

Boiler 2

Staging Voltage

Signal Outputs

Boiler Type = Hybrid

Condensing Boiler Type = Modulating

Condensing Boiler Number = 2

Condensing Output Type = 4-20ma

Condensing Modulating Mode = Parallel

Non-Condensing Boiler Type = Staging

Non-Condensing Output Type = 4-Stages

Non-Condensing Boiler Number = 2

Boiler Type = Hybrid

Condensing Boiler Type = Modulating

Condensing Boiler Number = 2

Condensing Output Type = Any voltage

Condensing Modulating Mode = Parallel

Non-Condensing Boiler Type = Staging

Non-Condensing Output Type = 4-Stages

Non-Condensing Boiler Number = 2

Loading...

Loading...