25

alignment checking.

NOTE: When using the Beam alignment subroutine you will also

need to refer to the following Renishaw publication for instructions on

how to physically align the beam at the transmitter unit:

n

NC1 Installation Guide and Parts List

(Renishaw Part No. H-2000-5048)

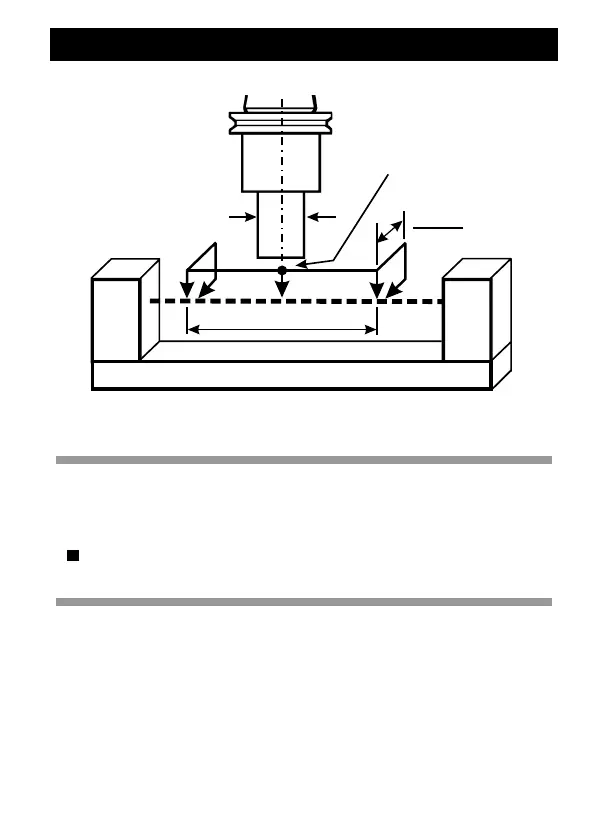

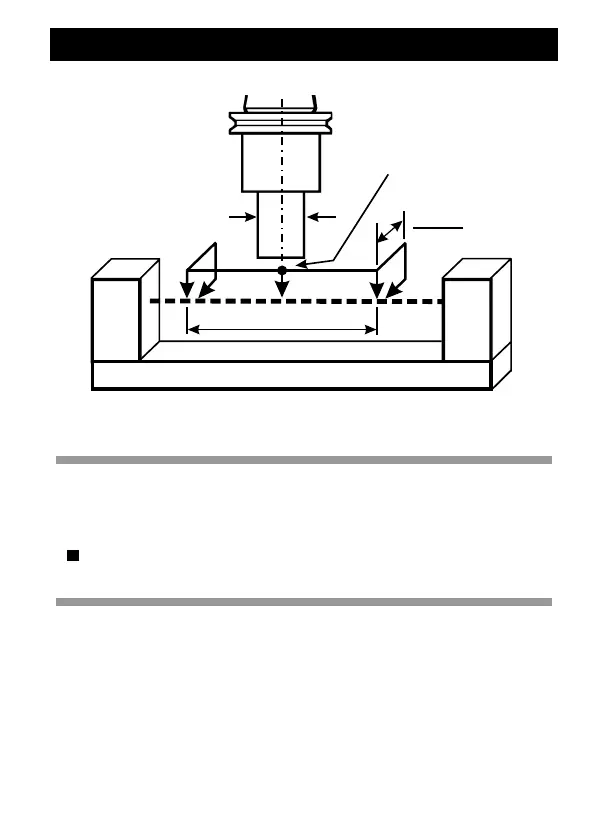

Calibration tool required

This cycle requires a calibration tool to be loaded in the spindle of the

machine. Ideally, this should be a solid, flat-bottomed, cylinder-type

tool having minimal runout. The exact setting length and diameter of

this tool must be known.

Beam alignment

Jog or

handwheel

to start point

R7=d

R18=r + R17=q

R18=r (+/–)

2

Loading...

Loading...