Automatic swarf extraction

The automatic swarf extraction is connected directly to the pressure plate

(Fig. 11) and extracts the resulting swarf that results during milling. Larger

swarf is separated to a swarf container directly below the pressure plate.

Smaller swarf is fed to a vacuum cleaner bag.

Note:

To ensure correct operation and to minimise the cleaning effort,

empty the swarf container and the vacuum cleaner bag in regu-

lar intervals.

3.1.11 Motorised depth adjustment (optional)

The motorised depth adjustment positions the placed cubes with changeable

overall depth on the machine. To do this, a motor-driven slide is traversed

backwards against the component in the clamping position when the push-

button is actuated.

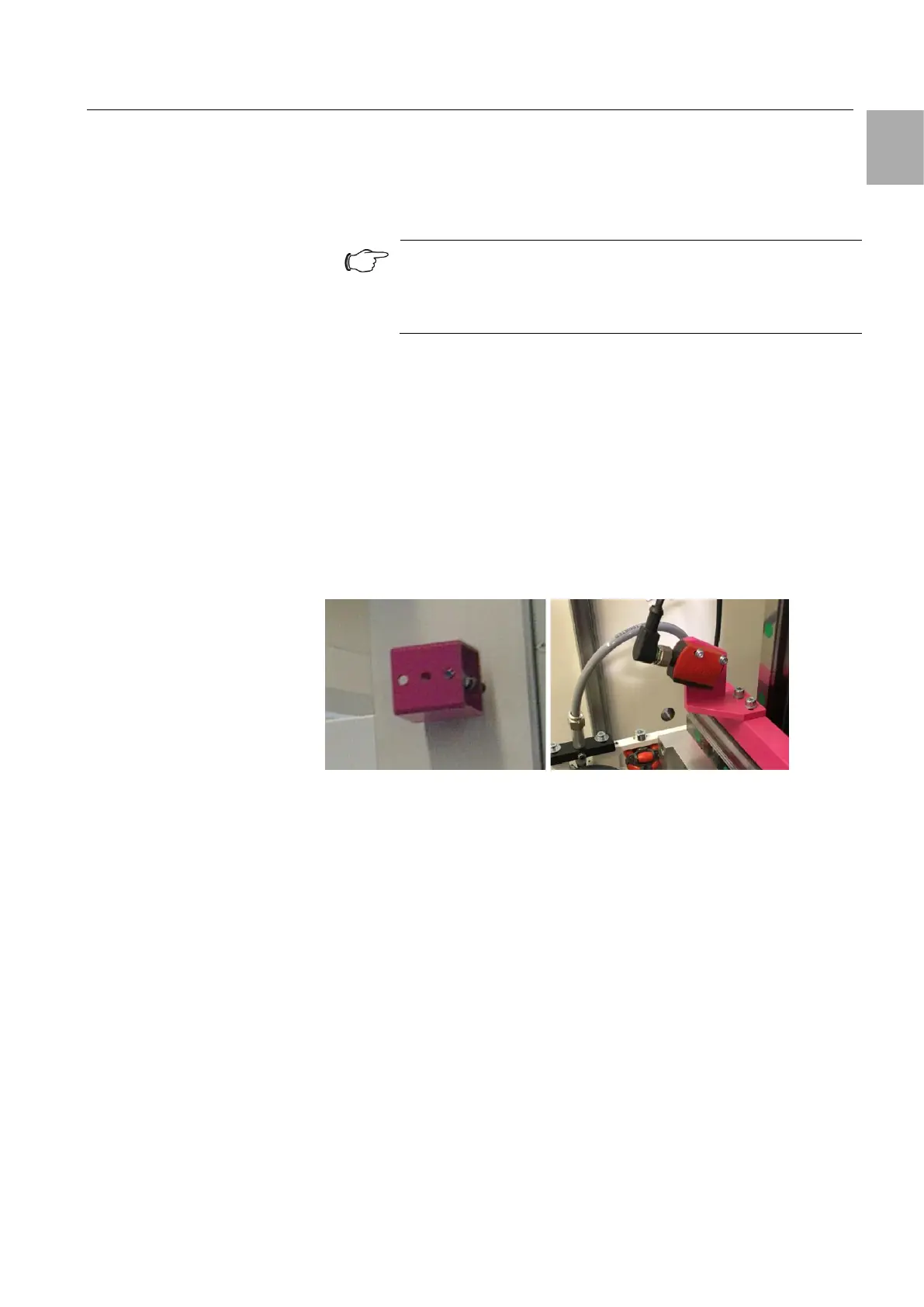

3.1.12 Automatic tool breakage check

The tool is checked after each work step and before storing the tool in the

tool magazine. This ensures that work steps are performed only with cor-

rectly functioning tools. The automatic tool breakage check is located either

above the tool magazine on the machine frame or directly on the cross-slide.

Fig. 12: Automatic tool check (left-hand side: BC 1001 HS, BC 1007 HS; right-hand

side: BC 1008 HS, BC 2014 HS)

3.1.13 Brush strips / Performance package (optional)

The optional brush strips simplify the component clamping and greatly re-

duce vibrations in the component. This reduces the noise level during ma-

chining and extends the service life of the tools.

Loading...

Loading...