Rockwell Automation Publication 1715-UM001J-EN-P - December 2020 237

Chapter 8 Using SIL 2 Add-On Instructions with 1715 Redundant I/O Modules

If you are not using COS, the worst-case reaction time from input screw

terminal to output screw terminal is equal to 210 ms plus the following:

- Input RPI

- Output RPI

- Add-On Instruction Module RPI/2

- SIL 2 Task Period x 2

- SIL 2 Task Watchdog x 2

If you are using COS, the worst-case reaction time from input screw terminal

to output screw terminal is equal to 270 ms plus the following:

- Output RPI

- Add-On Instruction Module RPI/2

- SIL 2 Task Period x 2

- SIL 2 Task Watchdog x 2

Using the Add-On

Instruction Data Tags in an

Application Program

The following illustrations provide basic examples of how the

Requested_Output_Data tag and the Reconciled_Input_Data tag could be used

in program logic. Data is written to the requested output and read from the

reconciled input, while the raw data in the module-defined input and output

tags is ignored.

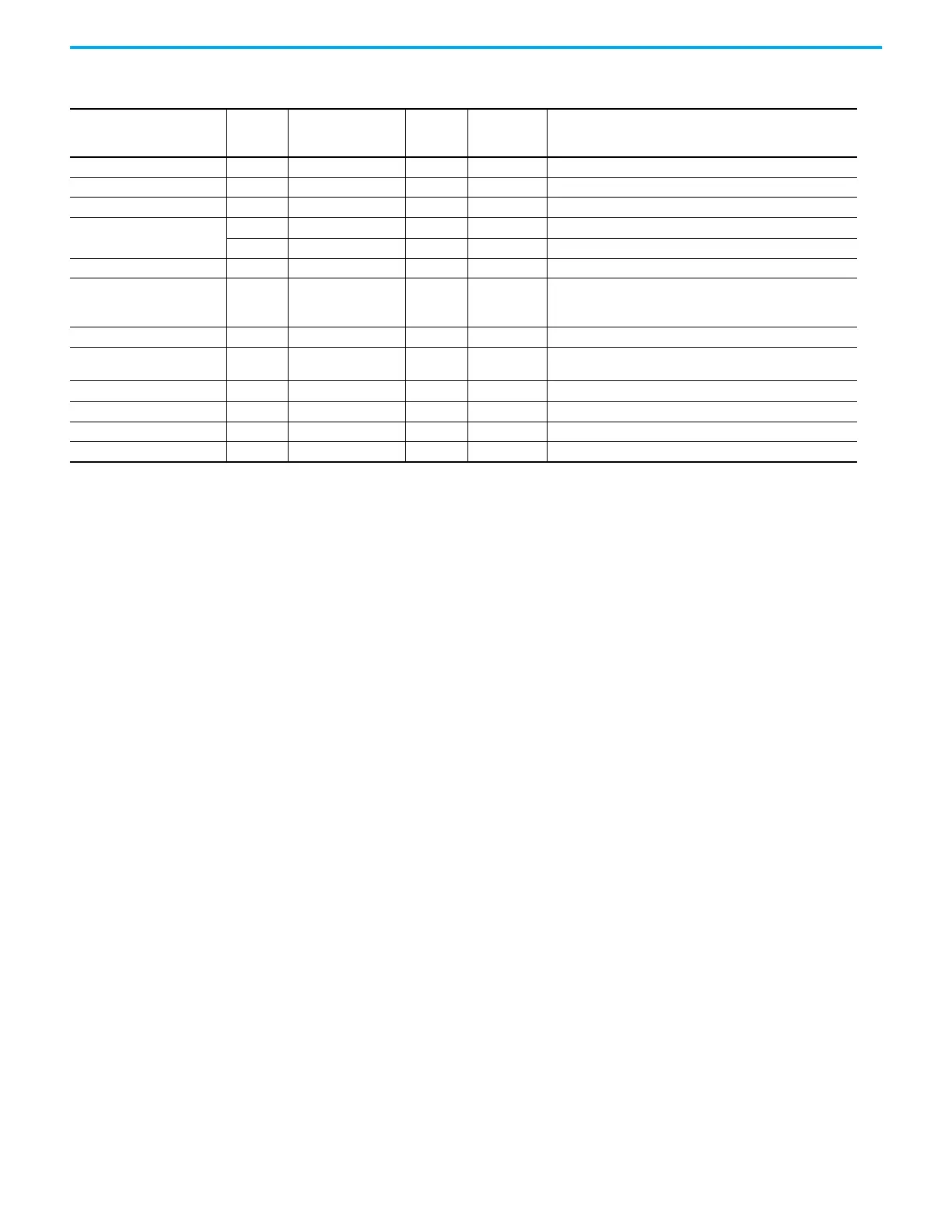

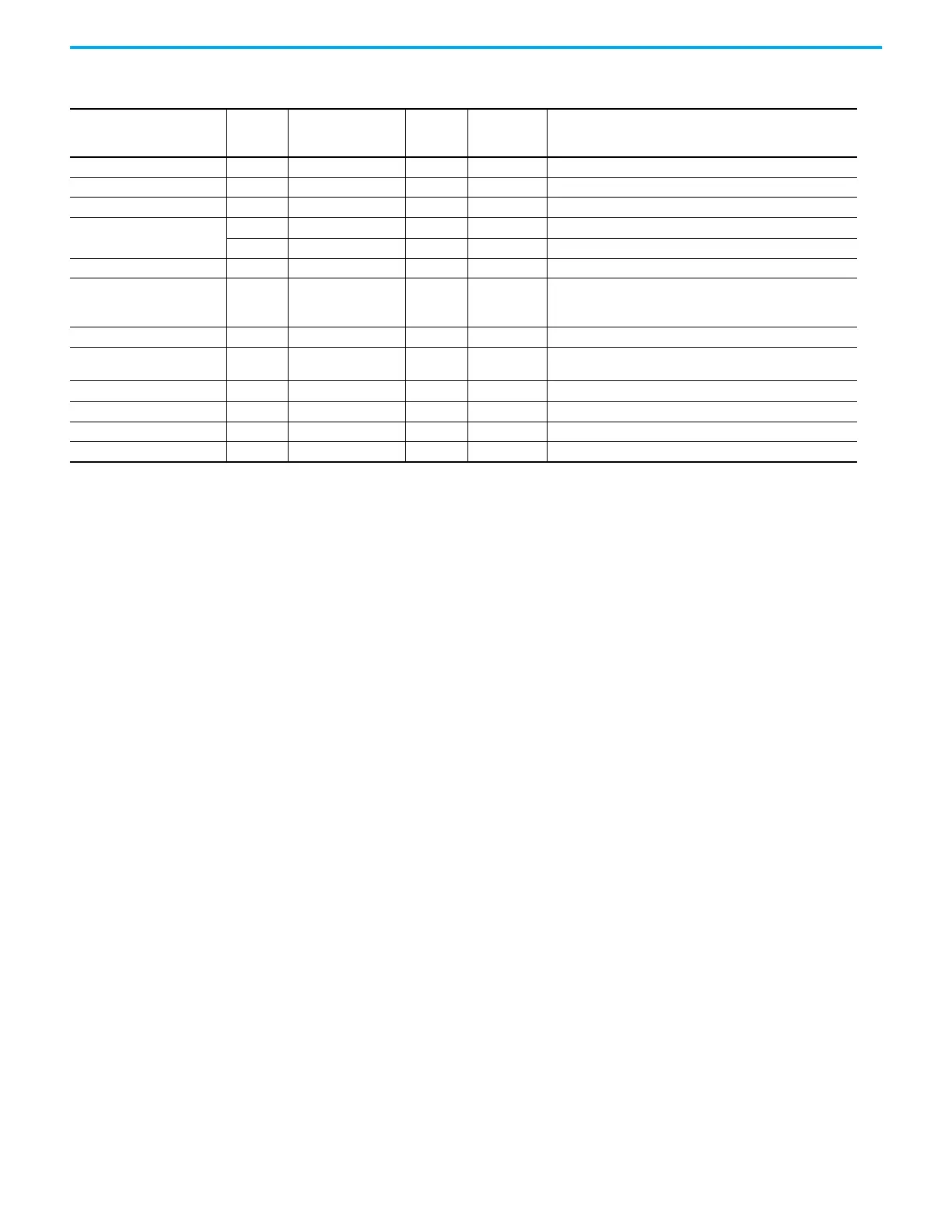

Table 48 - Worst Case Reaction Time Calculations

Worst Case Factors Value

Fixed Time

(ms)

User

Configurable

Time (ms)

Description

1715 Input Module Delay 15

1715 Backplane Rate 65

1715-AENTR Delay 25

Input Data to ControlLogix

COS=NO 1715 Input Module RPI 60 COS = Change of State

COS=YES Fixed 60

Add-On Instruction Module RPI AOI Module RPI/2 30 Value that is entered into the AOI Module_RPI parameter

ControlLogix SIL2 Task

Watchdog

SIL 2 Task Watchdog 20

ControlLogix system runs input module AOI and controls

requested output

Assumes requested output in same SIL 2 task as 1715 SIL 2 AOIs

Add-On Instruction Module RPI AOI Module RPI/2 30 Value that is entered into the AOI Module_RPI parameter

ControlLogix SIL2 Task

Watchdog

SIL 2 Task Watchdog 20

ControlLogix system runs output module Add-On Instruction and

places requested outputs in output module raw data

Output Data to 1715-AENTR 1715 Output Module RPI 80

1715-AENTR Delay 25

1715 Backplane Rate 65

1715 Output Module Delay 15

Loading...

Loading...