24 Rockwell Automation Publication 750-RM004A-EN-P - April 2018

Chapter 1 Selection Considerations

Power Source Grounding

The PowerFlex 755TL/TR drive safety ground (PE terminal) must be

connected to the power system ground. Ground impedance must conform to

the requirements of national and local industrial safety regulations and/or

electrical codes. Check the integrity of all ground connections periodically.

PowerFlex 700S AC input drives could be used with various grounding

methods. PowerFlex 755TL/TR drives can be used with similar grounding

methods. There are special considerations depending on the power source

grounding method. A single point (PE only) grounding scheme should be

used. Some applications may require alternate grounding schemes. These

applications include installations with long distances between drives or drive

line-ups, which could cause large potential differences between the drive or

line-up grounds. See Wiring and Grounding Guidelines for Pulse-width

Modulated (PWM) AC Drives, publication DRIVES-IN001

, for more

information.

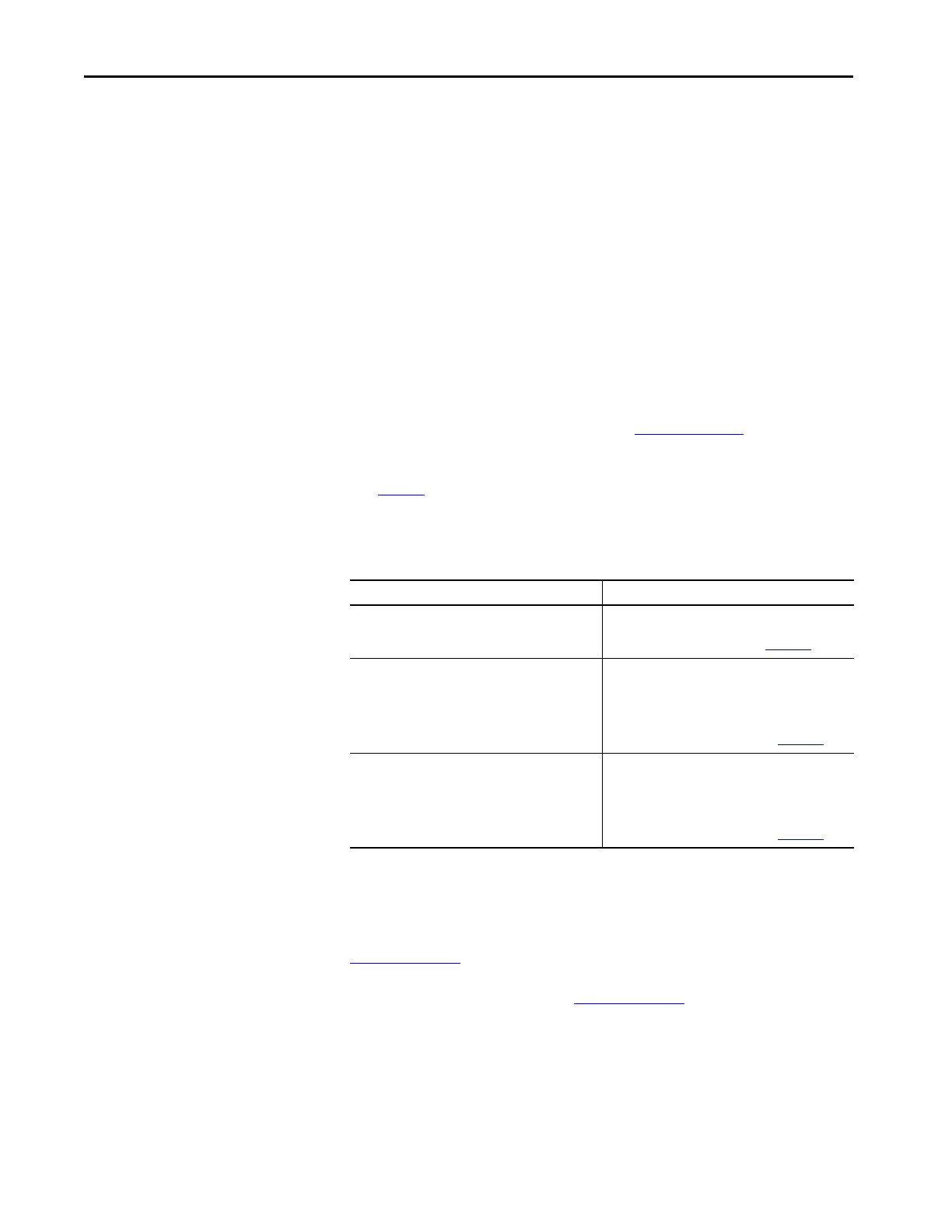

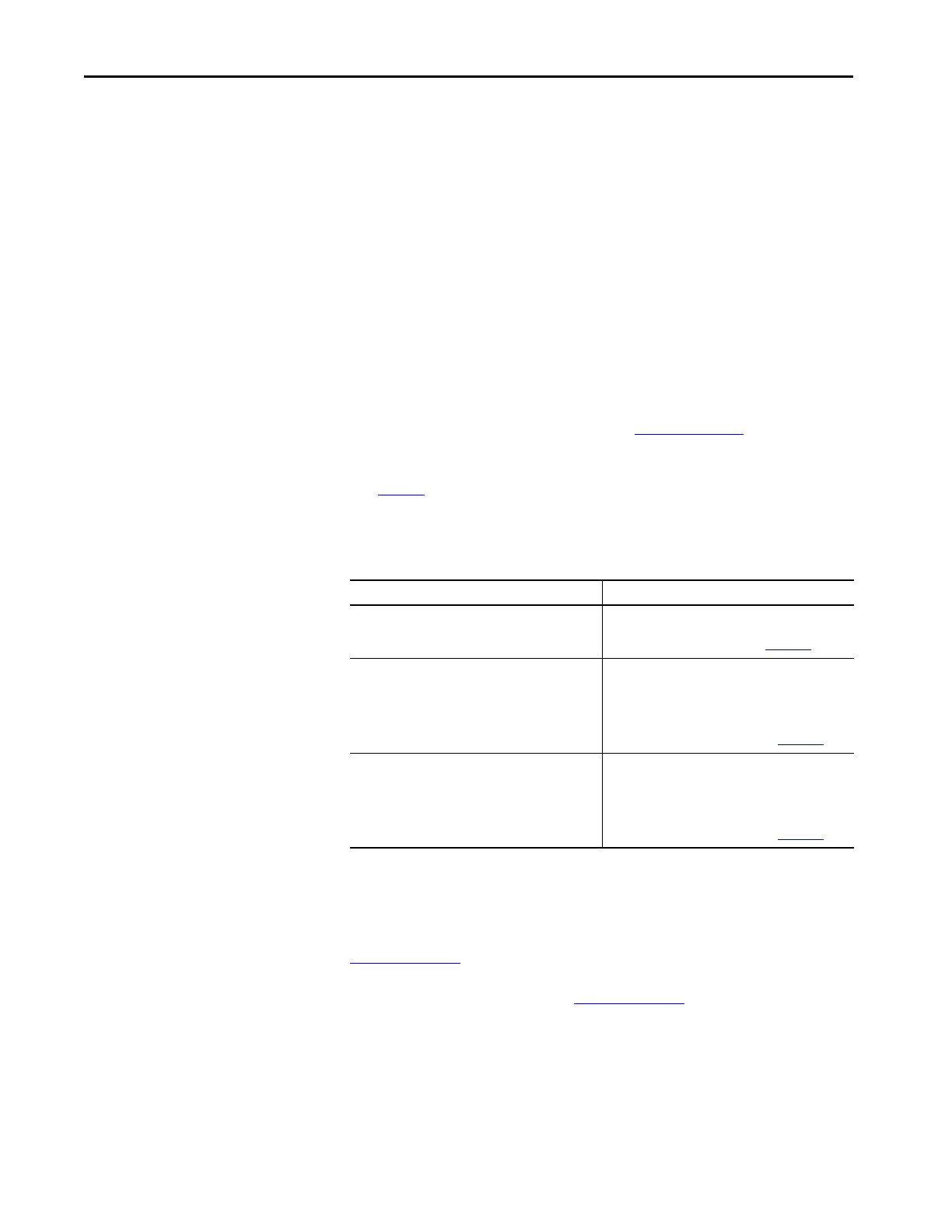

Use Table 3

as a guide to required power conditioning options for the

PowerFlex 755TL/TR drives. This table only refers to power conditioning as it

applies to AC power source grounding.

If you are using DC input common bus inverters, the power conditioning

requirements for the various grounding methods depend on the bus supply

converter being used. If you are using a PowerFlex 700AFE bus supply, see

Drives in Common Bus Configurations application technique, publication

DRIVES-AT002. If you are using a PowerFlex 755TM bus supply, refer to

Drives in Common Bus Configuration with PowerFlex 755TM Bus Supplies

application technique, publication DRIVES-AT005

.

Table 3 - AC Power Source Grounding Comparison

Power Source Grounding Method PowerFlex 755 TL/TR Drive Considerations

Wye secondary, X0 solid ground • DC Bus Conditioner not required.

• Power Filter Jumpers; PE-A/PE-A1/PE-A2, and PE-B1

jumpers installed per publication 750-IN100.

Wye secondary, X0 resistance grounded with ground

fault indicator

• Specify power option code (–P50) DC Bus

Conditioner. The drive is factory-shipped with the DC

Bus Conditioner(s) installed within the drive

enclosure.

• Power filter jumpers; PE-A/PE-A1/PE-A2, and PE-B1

jumpers must be set per publication 750-IN100.

Delta secondary, ungrounded with artificial ground (zig-

zag) transformer and ground fault indicator

• Specify power option code (–P50) DC Bus

Conditioner. The drive is factory-shipped with the DC

Bus Conditioner(s) installed within the drive

enclosure.

• Power filter jumpers; PE-A/PE-A1/PE-A2, and PE-B1

jumpers must be set per publication 750-IN100

.

Loading...

Loading...