Rockwell Automation Publication 750-RM004A-EN-P - April 2018 81

Selection Considerations Chapter 1

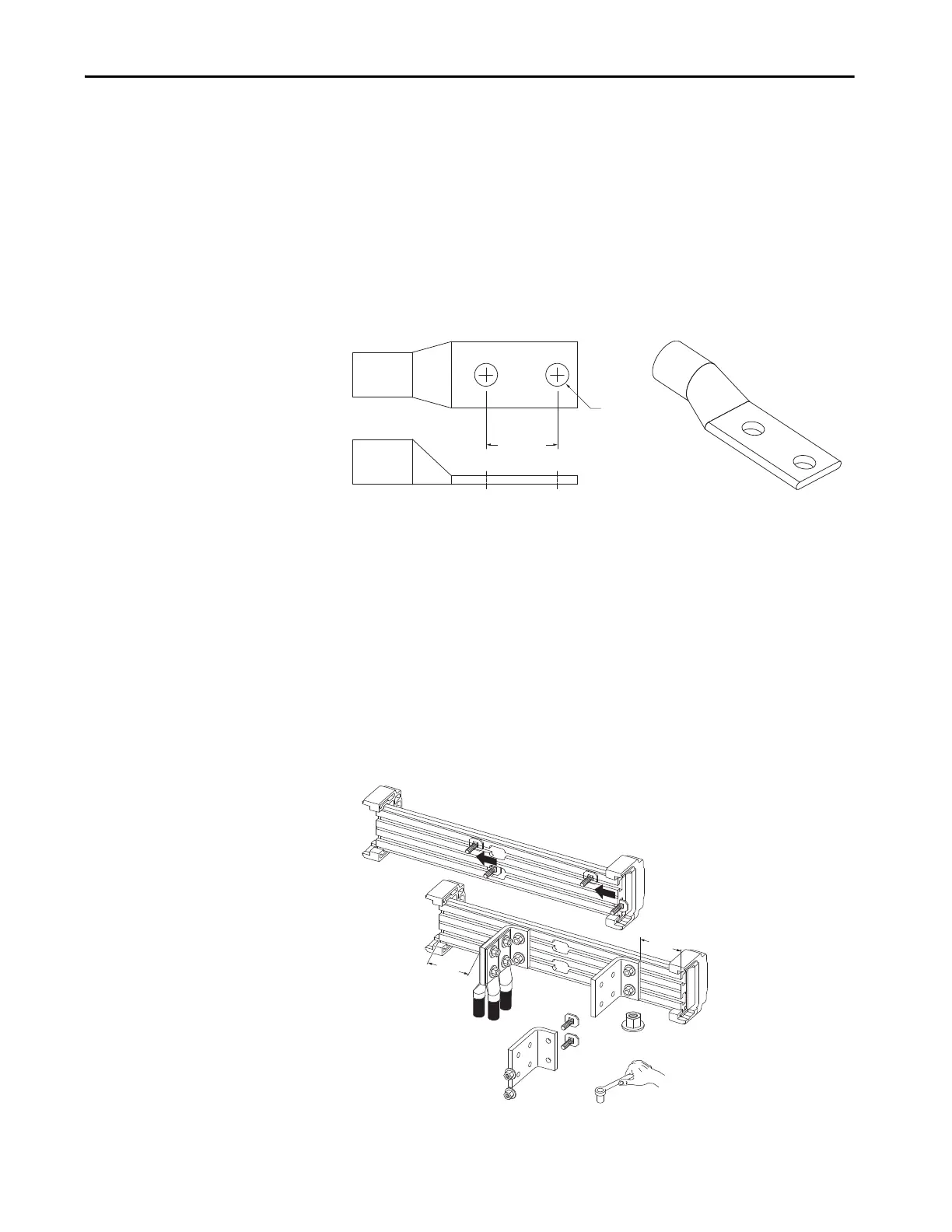

PowerFlex 755T Customer Power Terminal Locations and

Specifications

Customer Power Connections

AC line input power and output motor connections are made by using

customer-supplied barrel lugs that are either crimp or mechanical type. Barrel

lugs that are used to make the power cable connections to busbars must have

the dimensions in the following graphic.

Figure 18 - UL-listed Barrel Lug Dimensions

Use the vendor-recommended tooling to fasten crimp type terminals to

cabling. Torque mechanical type terminals according to vendor instructions.

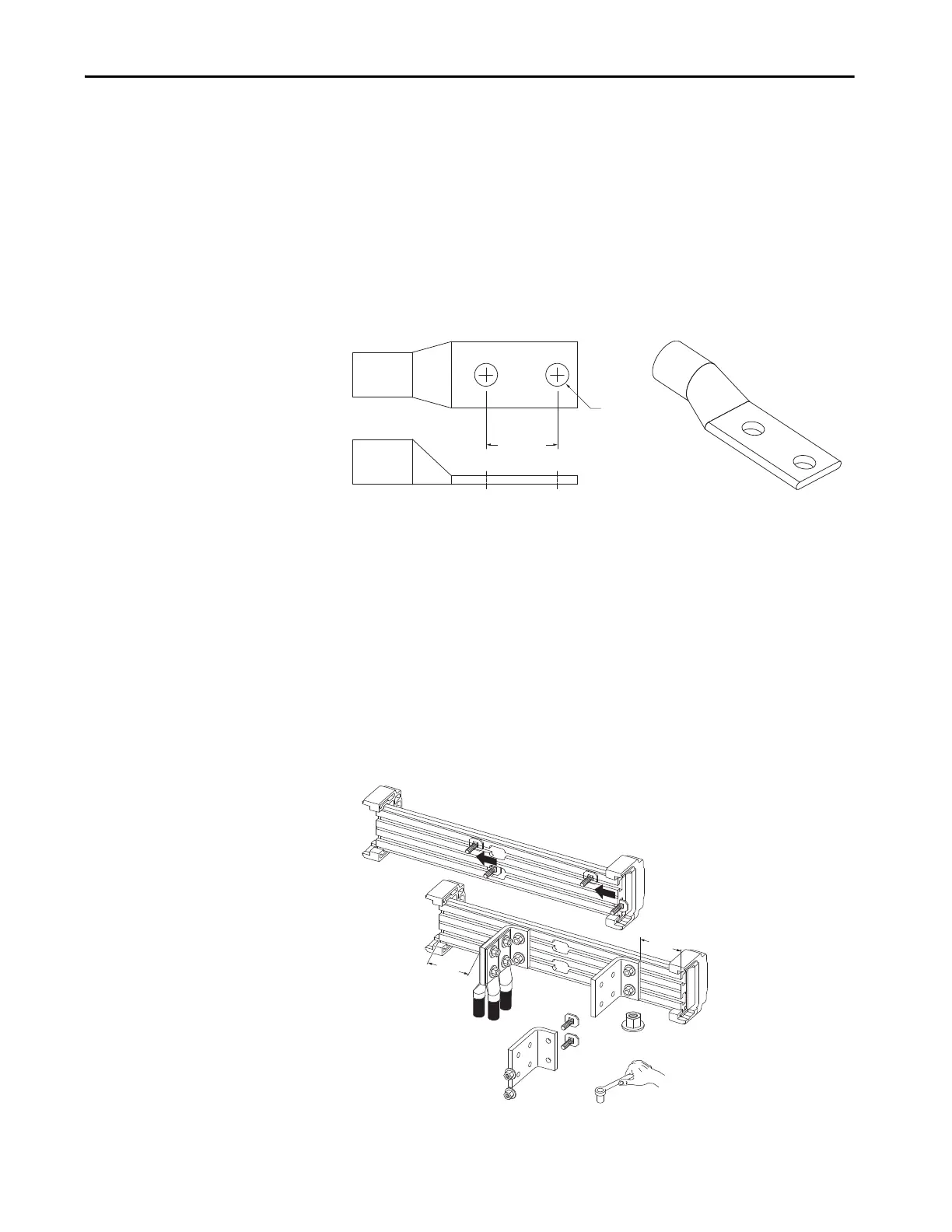

L-Bracket Connections

Power cable connections in entry and exit wire bay are made using L-brackets.

The M10 hardware that is required to fasten the L-brackets to the extruded

busbar is provided. Wires with appropriate barrel lugs can be bolted to both

sides of the L-brackets if necessary. Up to four conductors can be attached to

each L-bracket. Attach the conductors to the L-brackets using M12 or 0.5 in.

diameter bolts, nuts, and washers. Belleville spring washers, or equivalent, are

recommended. Keep the L-bracket connections at least 51 mm (2 in.) away

from the ends of the extruded busbar.

44.5 mm

(1.75 in.)

Ø 12.7 mm

(0.5 in.)

38.0 N•m (336 lb•in)

M10: 15 mm

M12: 19 mm

51 mm

(2 in.)

51 mm

(2 in.)

Cable Connections

Customer-supplied

M12 hardware.

Loading...

Loading...