36 Rockwell Automation Publication 750-RM004A-EN-P - April 2018

Chapter 1 Selection Considerations

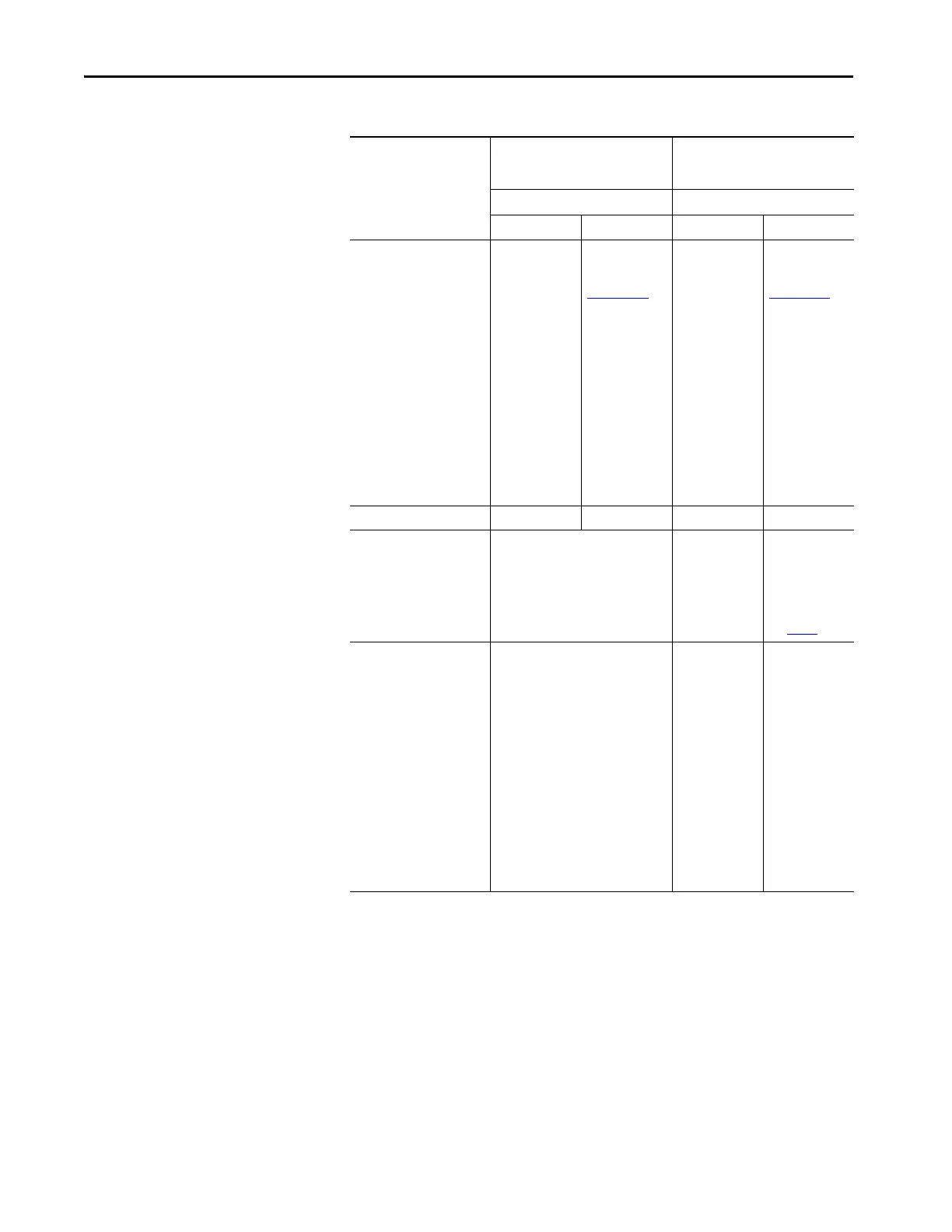

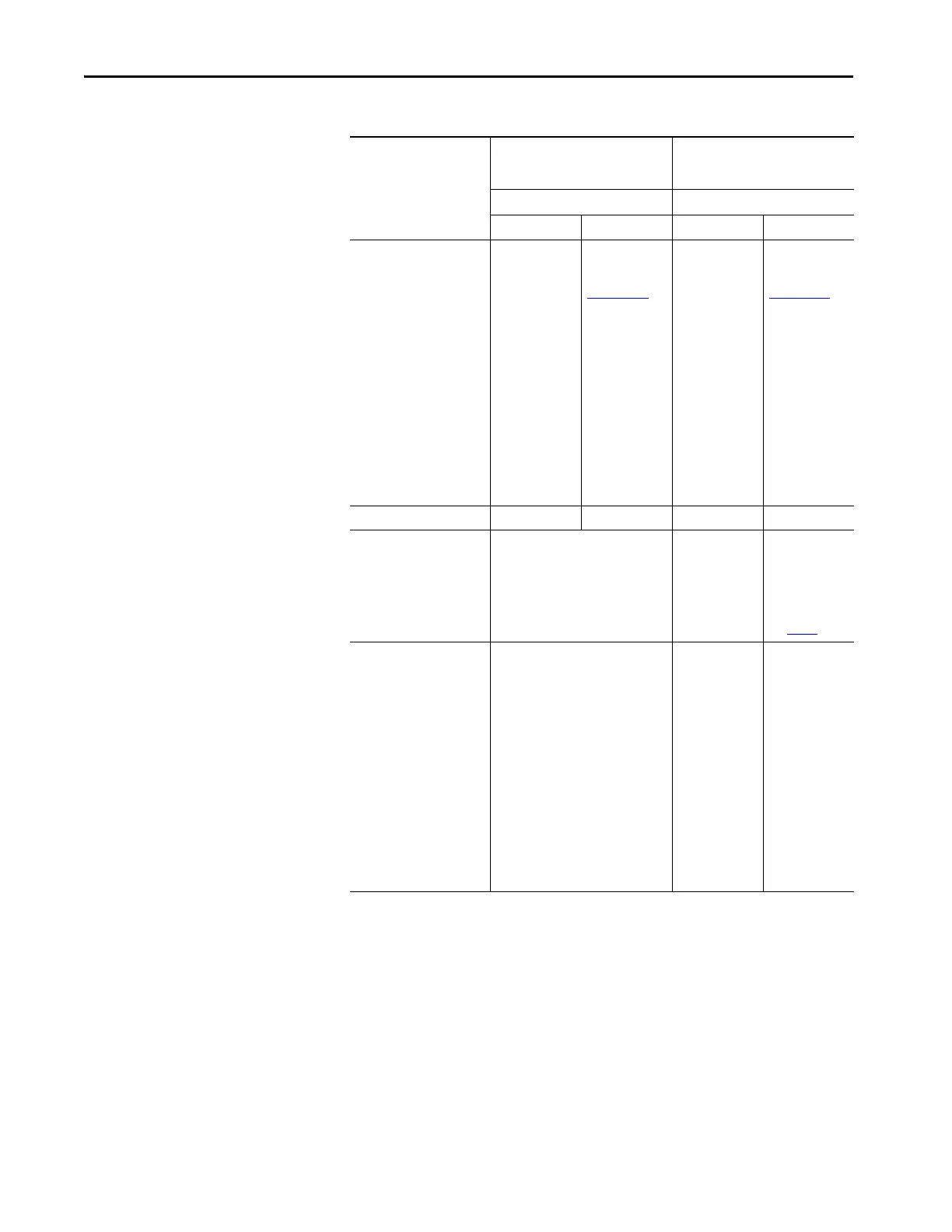

DC Bus Conditioner or Filter — (o) May be

required, refer to

publication

DRIVES-AT002

.

Installed external

to the active front

end enclosure.

(s) Installed

within the drive

enclosure.

(o) Additional

units may be

required

depending on

system grounding

method. Specify

power option

code (-P50) for

resistance or

ungrounded

power systems.

Optional units are

factory installed

within drive

enclosure.

May be required,

refer to

publication

DRIVES-AT005.

Installed within

the PowerFlex

755TM bus supply

enclosure.

Harmonic Compliance — — IEEE 519 —

Control Power (s) user-supplied control circuit power (s) Internal 240V

AC, 1 PH, 50/60 Hz

control

transformer

(s) user-supplied

240V AC, 1 PH,

50/60 Hz, neutral

grounded,

+/-10% of

nominal.

See Tabl e 5 .

Auxiliary 24V DC Control

Power

(o) Requires Auxiliary Power Supply

option board (20-24V-AUX1)

(o) user-supplied

24V DC +/-5% of

nominal;

Frame 8, 213 W

Frame 9, 276 W

Frame 10, 339 W

Frame 11, 402 W

Frame 12, 465 W

(o) Torque

Accuracy Module

(TAM);

All frames, add

5W

(o) user-supplied

24V DC +/-5% of

nominal;

Frame 8, 157 W

Frame 9, 188 W

Frame 10, 220 W

Frame 11, 251 W

Frame 12, 283 W

(o) Torque

Accuracy Module

(TAM);

All frames, add

5W

Table 6 - Input Power and Features (Continued)

Description PowerFlex 700S, F9…F14 PowerFlex 755TL/TR Drive and

PowerFlex 755TM Common Bus

Inverter, F8…F12

Cat. No. 20D… Cat. No. 20G…

AC Input DC Input 755TL/TR 755TM CBI

Loading...

Loading...