78 Rockwell Automation Publication 750-RM004A-EN-P - April 2018

Chapter 1 Selection Considerations

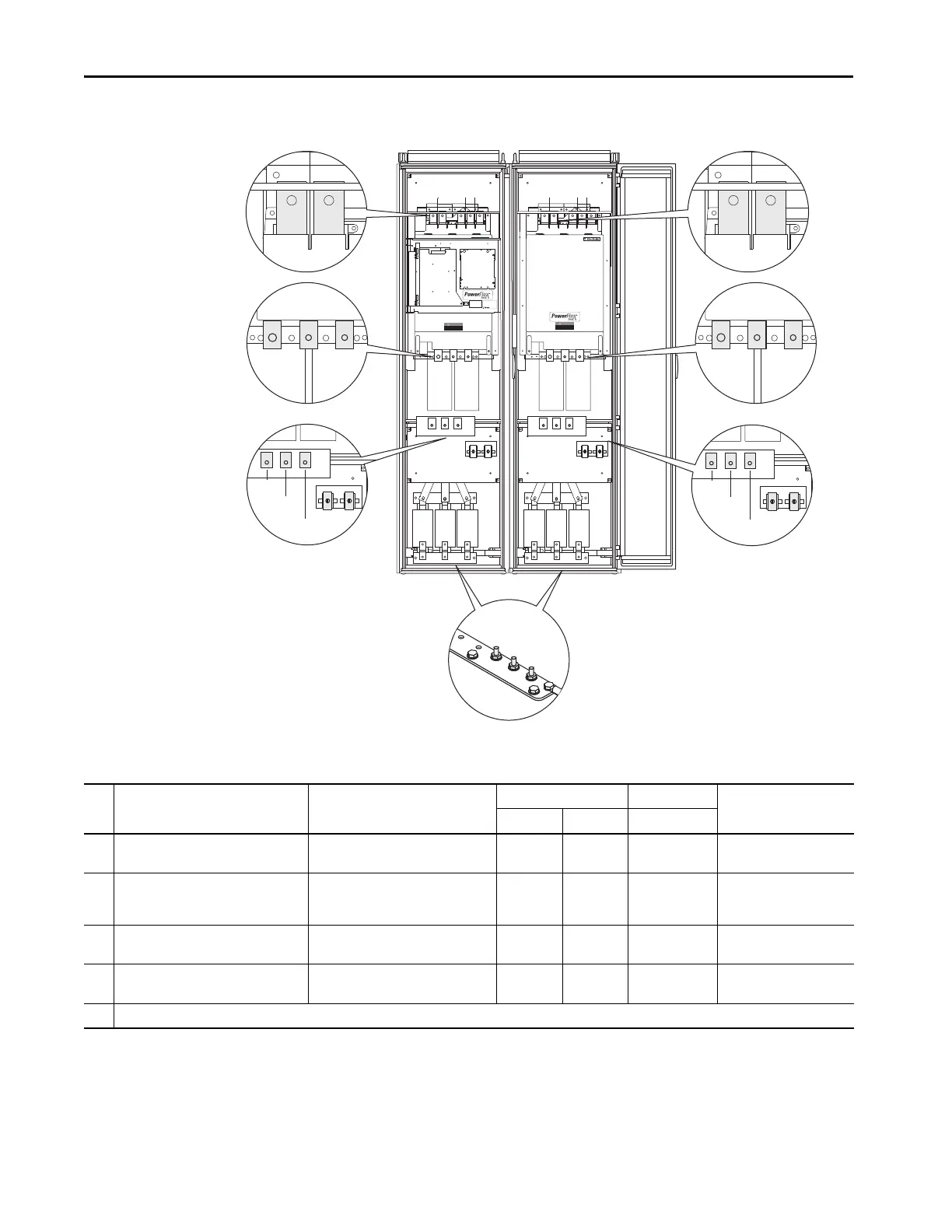

Figure 15 - PowerFlex 700S Frame 12 Power Terminal Locations

DANGER DANGER

DC BUS CONDUCTORS AND CAPACITORS

OPERATE AT HIGH VOLTAGE. REMOVE POWER

AND WAIT 5 MINUTES BEFORE SERVICING

DANGER DANGER

DC BUS CONDUCTORS AND CAPACITORS

OPERATE AT HIGH VOLTAGE. REMOVE POWER

AND WAIT 5 MINUTES BEFORE SERVICING

Cat No.

1234567890-*

FIELD INSTALLED OPTIONS:FIELD INSTALLED OPTIONS:

DC- DC+ DC- DC+

1L1

1L2

1L3

2L1

2L2

2L3

1U/T1

1V/T2

1W/T3

2U/T1

2V/T2

2W/T3

Enclosure Style A Shown

1155

3

2 2

4 4

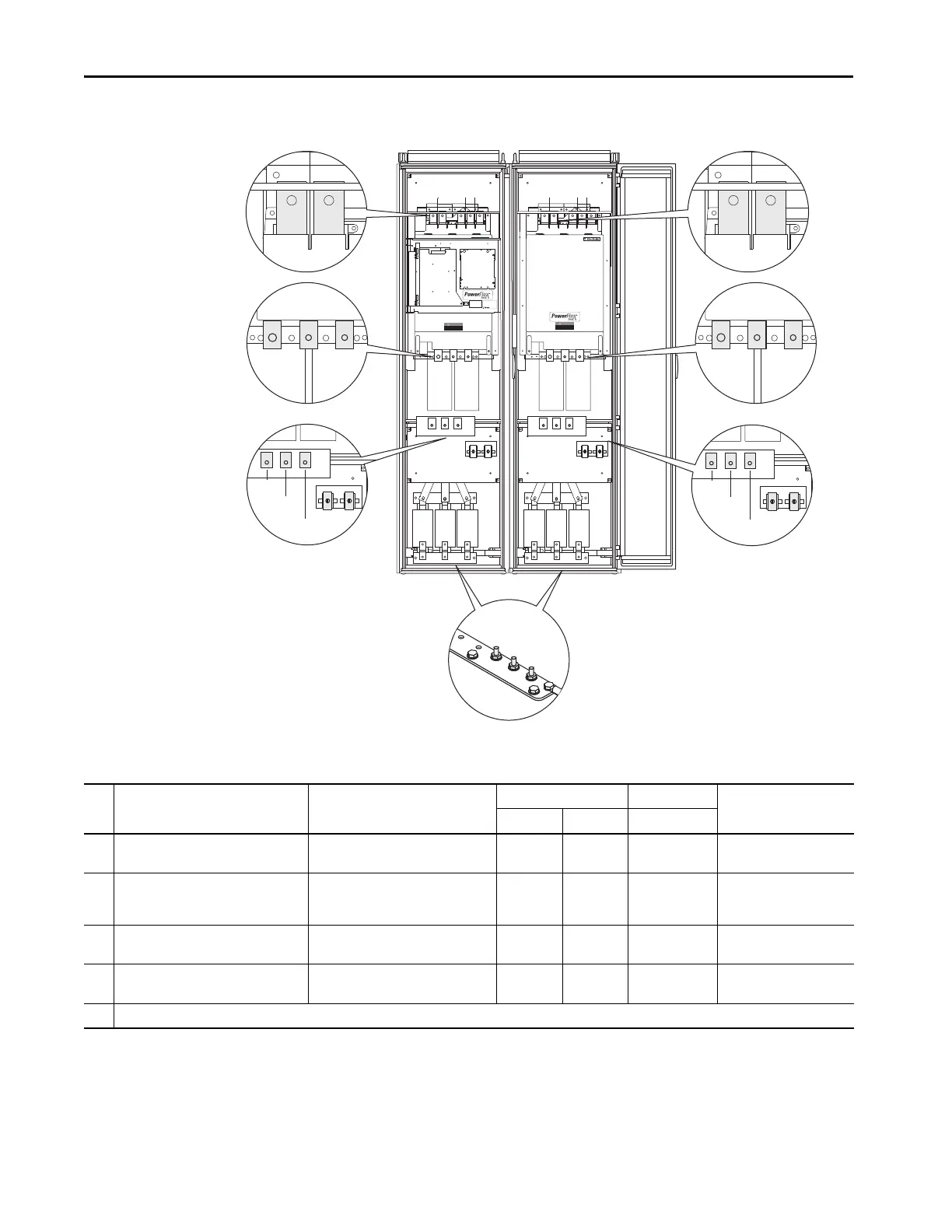

Table 42 - PowerFlex 700S Frame 12 Power Terminal Specifications

No. Name Description Wire Size Range

(1)(2)

Torque Terminal Bolt Size

(3)(4)

Maximum Minimum Recommended

1 Input Power Terminal Block

(3)

1L1, 1L2, 1L3, 2L1, 2L2, 2L3

Input power 300 mm

2

(600 MCM)

2.1 mm

2

(14 AWG)

40 N•m

(354 lb•in)

M12

2 Output Power Terminal Block

(3)

1U/1T1, 1V/1T2, 1W/1T3,

2U/2T1, 2V/2T2, 2W/2T3

Motor connections 300 mm

2

(600 MCM)

2.1 mm

2

(14 AWG)

40 N•m

(354 lb•in)

M12

3 SHLD Terminal, PE, Motor Ground

(3)

Terminating point for wiring shields 300 mm

2

(600 MCM)

2.1 mm

2

(14 AWG)

40 N•m

(354 lb•in)

M10

4 DC Bus

(3)

(2 Terminals; DC–, DC+)

DC input or external brake 300 mm

2

(600 MCM)

2.1 mm

2

(14 AWG)

40 N•m

(354 lb•in)

M12

5 Cable Clamp for Shield

(1) Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

(2) Do Not exceed maximum wire size. Parallel connections may be required.

(3) These connections are Busbar type terminations and require the use of lug type connectors.

(4) Apply counter torque to the nut on the other side of terminations when tightening or loosening the terminal bolt to avoid damage to the terminal.

Loading...

Loading...