Chapter 3

PowerFlex 700S Control Wiring

I/O Wiring

Important points to remember about I/O wiring:

• Always use copper wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

• 4100CCF3 Flex I/O cable for use with DriveLogix is 3 ft. maximum

length

.

Important: I/O terminals labeled “(–)” or “Common” are not referenced to

earth ground and are designed to greatly reduce common mode

interference. Grounding these terminals can cause signal noise.

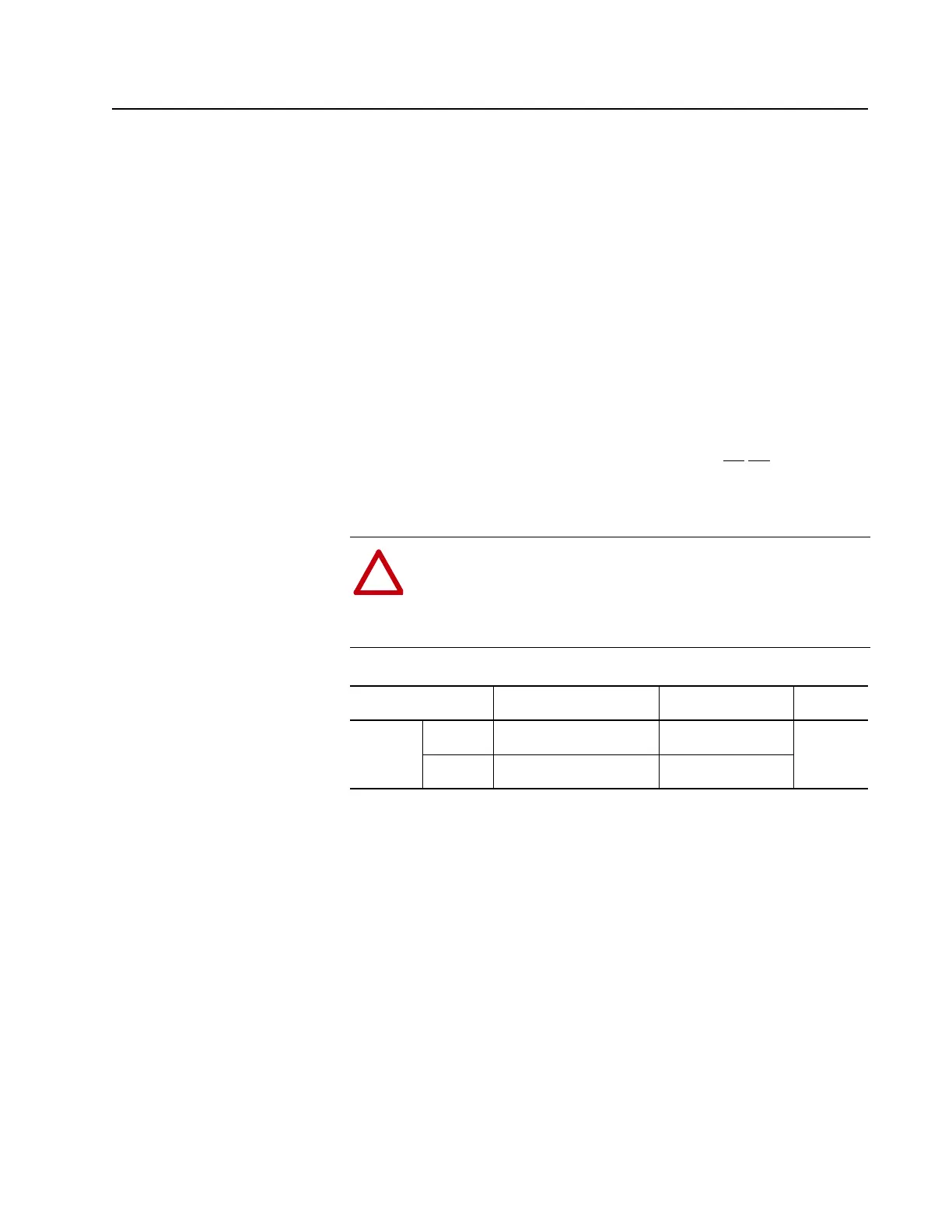

Table 3.A Recommended Control Wire

!

ATTENTION: Hazard of personal injury or equipment damage

exists when using bipolar input sources. Noise and drift in sensitive

input circuits can cause unpredictable changes in motor speed and

direction. Use speed command parameters to help reduce input

source sensitivity.

Type Wire Type(s) Description

Insulation

Rating

Digital I/O Un-shielded Per US NEC or applicable

national or local code

–

300V, 60

o

C

(140

o

F),

Minimum

Shielded Multi-conductor shielded cable

such as Belden 8770(or equiv.)

0.750 mm

2

(18AWG), 3

conductor, shielded.

Loading...

Loading...