120 Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

Chapter 1 Detailed Drive Operation

cable transient. Thus, the second pulse arrives at a point in the motor terminal

voltage's natural response and excites a motor overvoltage transient greater than 2

p.u. The amplitude of the double-pulsed motor overvoltage is determined by a

number of variables. These include the damping characteristics of the cable, bus

voltage, and the time between pulses, the carrier frequency, modulation

technique, and duty cycle.

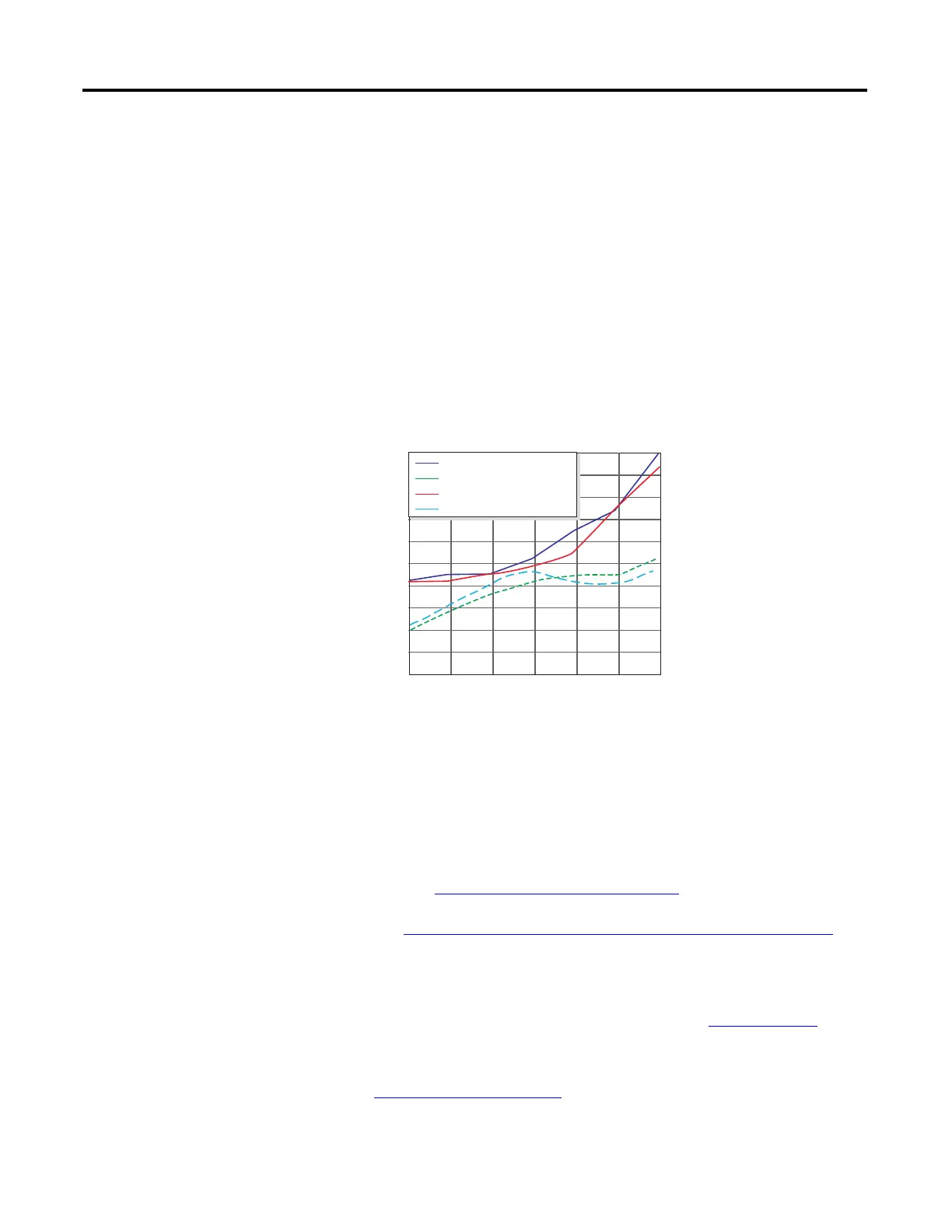

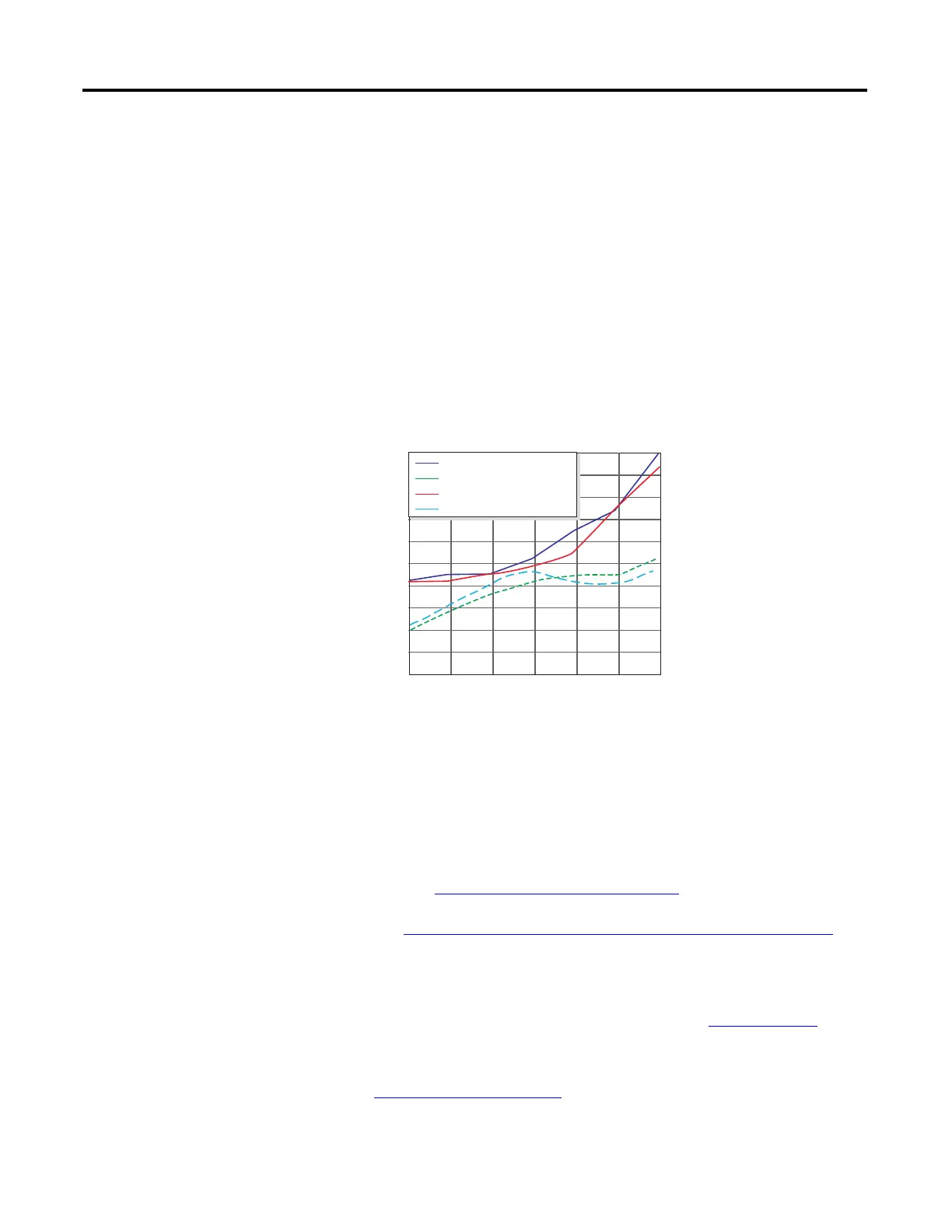

The plot below shows the per unit motor overvoltage as a function of cable

length. This is for no correction versus the modulation correction code for varied

lengths of #12 AWG cable to 600 ft for 4 and 8 kHz carrier frequencies. The

output line-to-line voltage was measured at the motor terminals in 100 ft

increments.

Without the correction, the overvoltage increases to unsafe levels with increasing

cable length for both carrier frequencies. The patented modulation correction

code reduces the overvoltage for both carrier frequencies and maintains a

relatively flat overvoltage level for increasing cable lengths beyond 300 ft.

To determine the maximum recommended motor cable lengths for a particular

drive refer to Cable, Lengths for Motors

on page 26.

Refer to http://www.ab.com/support/abdrives/documentation/index.html

for

detailed technical papers.

RFI Filter Grounding

Refer to the Wiring and Grounding Guidelines for Pulse Width Modulated

(PWM) AC Drives Installation Instructions, publication DRIVES-IN001

, for

detailed information.

S-Curve

See Speed Reference on page 145.

No Correction vs Correction Method at 4 kHz and 8 kHz Carrie

Frequencies - Vbus = 650, fe = 60 Hz

Cable Length (Feet)

per Unit Vout/Vbus

1.6

1.7

1.8

1.9

2

2.1

2.2

2.3

2.4

2.5

2.6

1000 200 400 600300 500

No Correction 4 kHz Carrier

Corrected 4 kHz Carrier

No Correction 8 kHz Carrier

Corrected 8 kHz Carrier

Loading...

Loading...