164 Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

Chapter 1 Detailed Drive Operation

Torque Regulation Mode

A torque regulated application can be described as any process requiring some

tension control. An example is a winder or unwinder with material being “drawn”

or pulled with a specific tension required. The process also requires that another

element set the speed. Configuring the drive for torque regulation requires

parameter 110 [Speed/TorqueMode] to be set to 2 “Torque Ref ”. In addition, a

reference signal must be linked to the torque reference. For example, when analog

input 1 is used for the reference, link parameter 111 [Torque Ref1] to parameter

800 [Anlg In1 Data].

When operating in a torque mode, the motor current will be adjusted to achieve

the desired torque. If the material being wound/unwound breaks, the load will

decrease dramatically and the motor can potentially go into a “runaway”

condition.

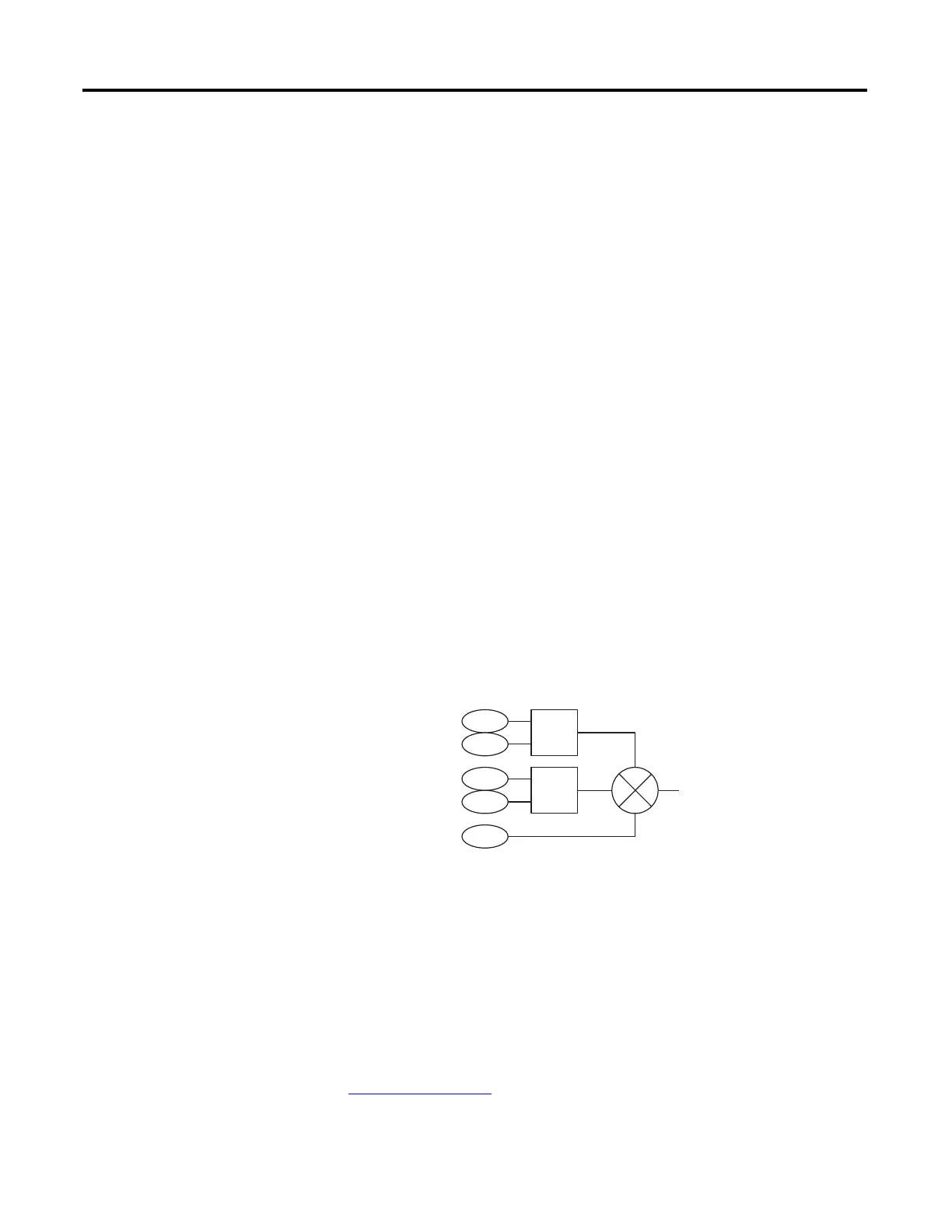

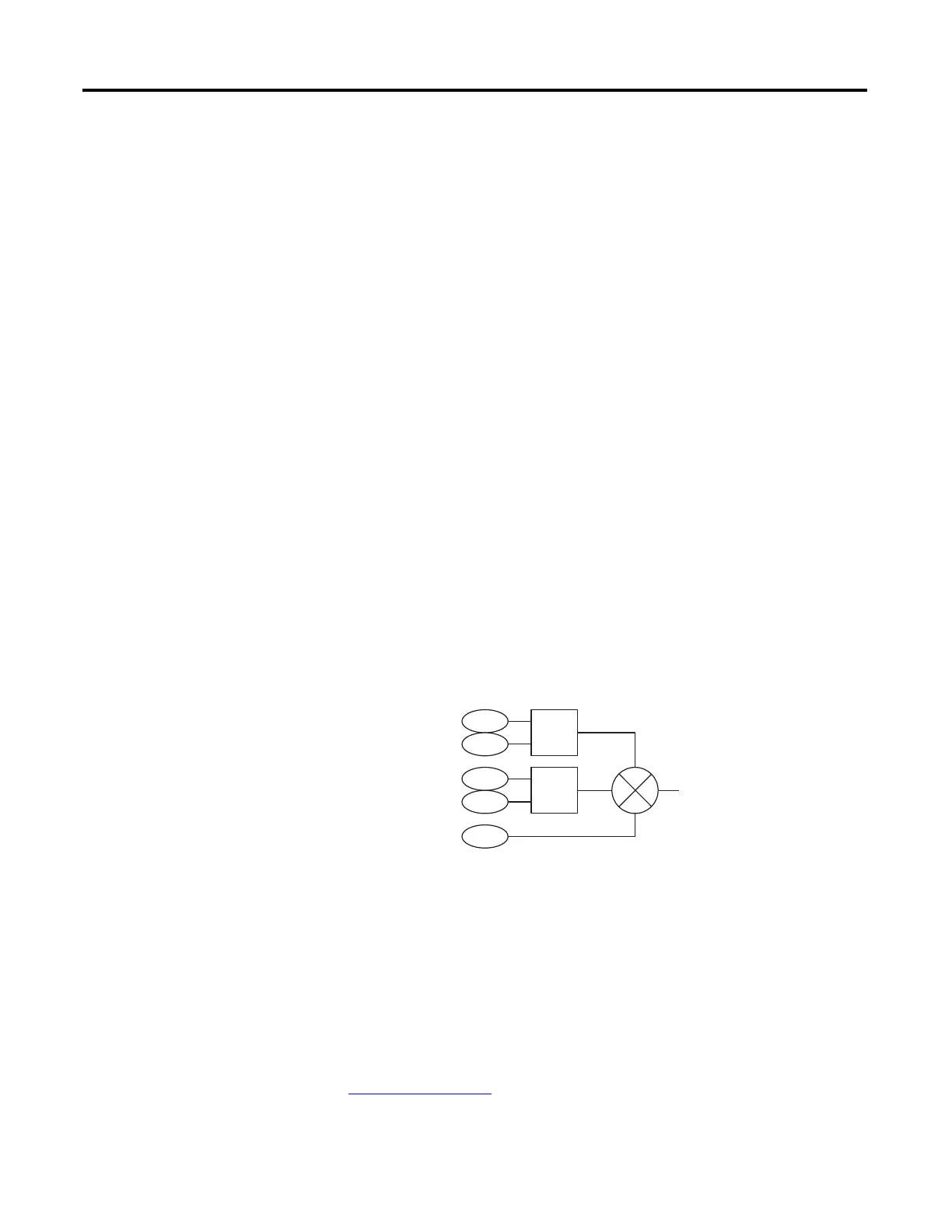

Torque Reference:

Parameter 111 [Torque Ref1] is divided by parameter 112 [Torq Ref1 Div]

Parameter 113 [Torque Ref2] is multiplied by parameter 114 [Torq Ref2 Mult]

Parameter 115 [Torque Trim] can be used to trim the torque. For example,

[Torque Trim] can be linked to an analog input or to the Process PI output.

The final torque reference, in torque mode, is the sum of scaled [Torque Ref1],

scaled [Torque Ref2], and [Torque Trim].

Min Speed / Torque Mode and Max Speed / Torque Mode

This operating mode compares the speed and torque commands. The

algebraically minimum value is used. Instead of operating the drive as a pure

torque regulator, the “runaway” condition can be avoided by limiting the speed. A

winder is a good example for the application of the minimum speed/torque

(“Min Spd/Trq”) operating mode. Maximum speed/torque (“Max Spd/Trq”)

mode would be used if both speed and torque are negative.

Figure 26 on page 165

illustrates how minimum speed/torque mode operates.

The drive starts out operating as a torque regulator. The torque reference causes

the motor to operate at 308 rpm. The speed reference is 468 rpm, so the

111

X

112

113

114

115

/

+

+

+

Torque Ref 1

Torq Ref1 Div

Torque Ref 2

Torq Ref2 Multi

Torque Trim

Loading...

Loading...