198 Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011

Chapter 1 Detailed Drive Operation

• Set parameter 861 [BitSwap 1A Bit] = 1. This parameter sets the bit that

you would like to turn on in the result, and is set to bit 1 because we want

to use bit swap 1 to turn on bit 1 “Spd S Crv En” of parameter 151 [Logic

Command].

• Link parameter 862 [Bit Swap 1B Data] to parameter 824 [Local I/O

Status]. Parameter 862 [Bit Swap 1B Data] sets the data that you would

like to compare.

• Set parameter 863 [BitSwap 1B Bit] = 3. This parameter indicates that bit

3 of parameter 824 is used. Bit 3 of parameter 824 [Local I/O Status]

indicates that digital input 3 has turned on.

• Link parameter 151 [Logic Command] to parameter 864 [BitSwap 1

Result]. The result of bit swap 1 will control parameter 151.

The overall function of BitSwap 1 is that when digital input 3 turns on, we turn

on bit 1 “Spd S Crv En” of parameter 151 [Logic Command].

For another example using multiple bitswaps and the 16 position selector switch

to control the point to point position with digital inputs see Position Loop -

Point to Point on page 96.

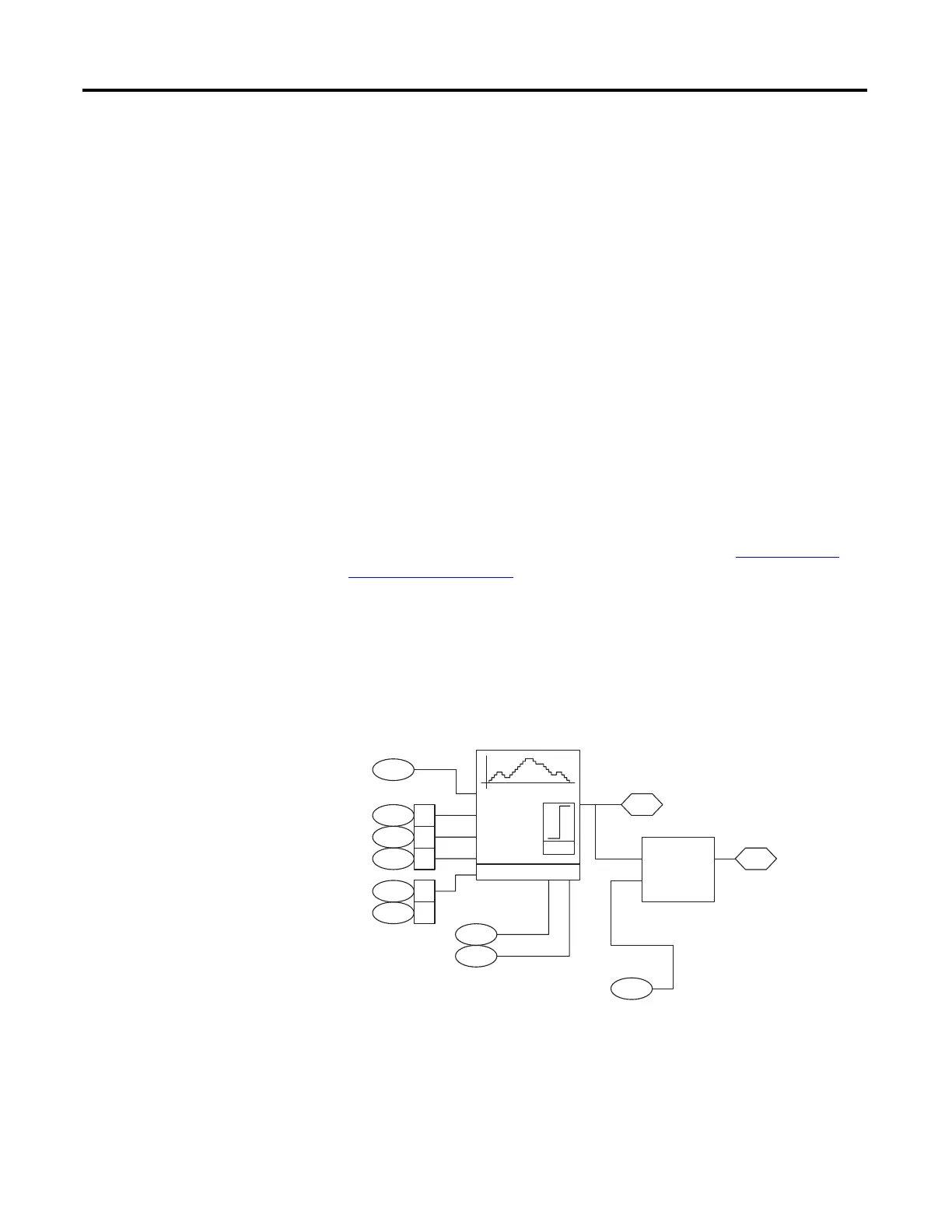

MOP

The motor operated potentiometer (MOP) allows you to increase and decrease a

DInt (double integer) or floating point value using two inputs. The inputs can

come from digital inputs, a network, or DriveLogix.

1087

1086 00

1086 01

1086 02

MOP

Rate

Increment

Decrement

Reset

Limit

1088

1089

1086 03

1086 04

1090

MOP High Limit

MOP Low Limit

1092

Convert

DInt-Real

x Scale

1091MOP Scale DInt

MOP Rate

MOP Control

MOP Level Real

MOP Level DInt

Loading...

Loading...