Rockwell Automation Publication PFLEX-RM003E-EN-E - January 2011 29

Detailed Drive Operation Chapter 1

Datalinks:

In the ControlLogix system, Datalinks are transmitted as DInt. In order to send

or receive Real (floating-point) parameters a COP (copy) instruction must be

utilized. The copy instruction in ControlLogix performs a bitwise copy. Set the

length of the copy instruction to a value appropriate for the destination data type.

Example to write a floating point Datalink:

Parameter 125 [Torque Pos Limit] sets the positive torque limit for the motor.

[Torque Pos Limit] is a Real (floating point) parameter scaled in per unit (a value

of 1.000 is equivalent to 100% motor torque). This example will write [Torque

Pos Limit] with a Datalink.

1. Link parameter 125 [Torque Pos Limit] to parameter 651 [DPI Data In

A1].

2. Set parameter 650 [DPI In DataType] bit 0 “DPI A1 Real” = 1.

3. Verify that the Datalink is enabled in the 20-COMM module.

4. In RSLogix5000, create a tag “PF700S_P125_TorquePosLimit” of type

“REAL.”

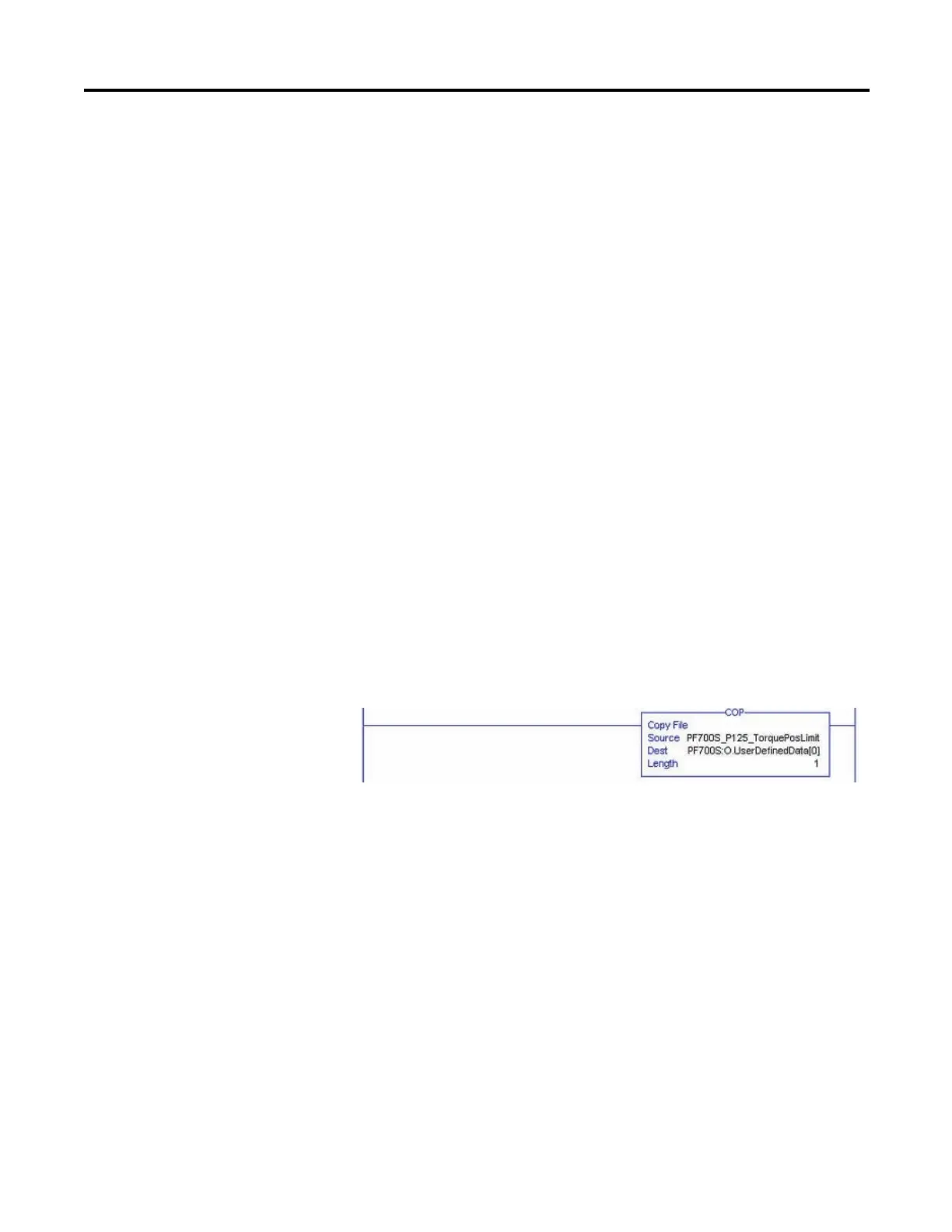

5. Use the COP instruction to copy the tag

“PF700S_P125_TorquePosLimit” to the DINT output tag for Datalink

A1 (PF700S:O.UserDefinedData(0) in this example).

6. A value of 1.000 in the tag “PF700S_P125_TorquePosLimit” will write a

value of 1.000 to parameter 125 in the drive.

Example to read a floating point Datalink:

Parameter 303 [Motor Torque Ref ] displays the torque output to the motor.

Parameter 303 is a Real (floating point) parameter scaled in per unit (a value of

1.000 is equivalent to 100% motor torque).

1. Link parameter 660 [DPI Data Out A1] to parameter 303 [Motor Torque

Ref].

2. Set parameter 659 [DPI Out DataType] bit 0 “DPI A1 Real” = 1.

3. Verify that the Datalink is enabled in the 20-COMM module.

4. In RSLogix5000, create a tag “PF700S_P303_MotorTorqueRef ” of type

“REAL.”

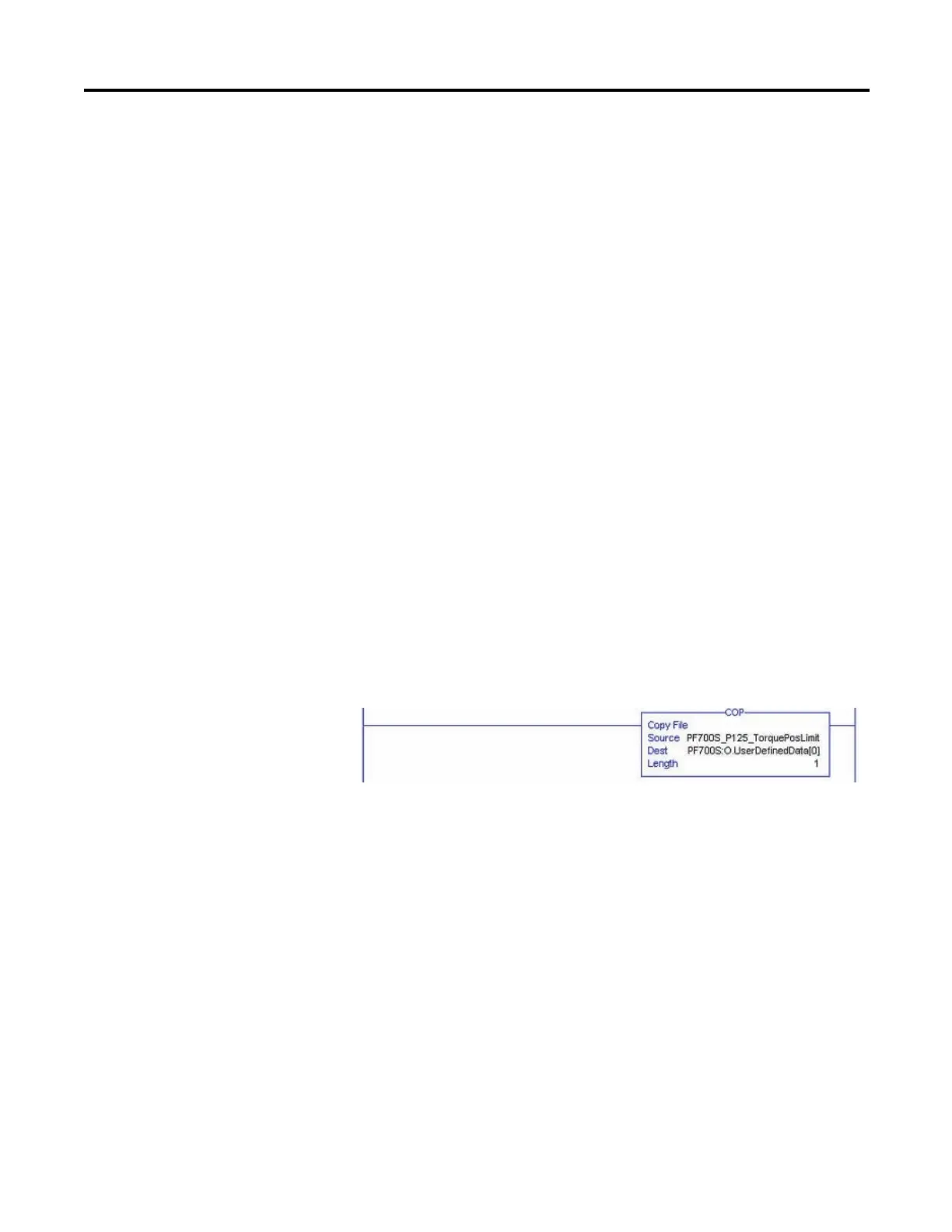

5. Use the COP instruction to copy the DINT input tag for Datalink A1

(PF700S:I.UserDefinedData(0) in this example) to the tag

“PF700S_P303_MotorTorqueRef.”

Loading...

Loading...