32 Rockwell Automation Publication 750-TG101A-EN-P - June 2022

Chapter 3 Component Inspection and Tests

7. For frames 6 and 7, inspect the power interface, and AC precharge or DC

precharge circuit boards. If any components, particularly the resistors,

show evidence of burn marks or breakage, replace the circuit board

without further testing.

• For frame 6 power interface circuit board, see page 106

.

• For frame 6 AC precharge circuit board, see page 113

.

• For frame 6 DC precharge circuit board, see page 119

.

• For frame 7 power interface circuit board, see page 151

.

• For frame 7 AC precharge circuit board, see page 161

.

• For frame 7 DC precharge circuit board, see page 170

.

Forward and Reverse Biased

IGBT/Diode Tests

Follow these steps to perform forward and reverse biased IGBT/diode tests on

the power modules. A failed test indicates damage to the components in the

power modules and requires replacement of the drive.

1. Review the Product Advisories

on page 11.

2. Remove power from the system. See Remove Power from the System

on

page 12.

3. Select the “Diode Test” mode on the digital multi-meter and complete the

forward and reverse biased diode tests on the power module for your

product frame size. See Figure 1 on page 13

and Figure 2 on page 14 for

terminal locations and identification.

4. If the product fails the measurements that are identified in Table 1

or

Table 2

, replace the drive.

5. Complete the procedures in Appendix A on page 179

before placing the drive

back into service.

IMPORTANT The actual voltage readings can vary depending upon your equipment. If

your readings are not near the indicated values in Table 1

and Table 2 verify

that the actual voltage that is measured is consistent for each phase of the

power module.

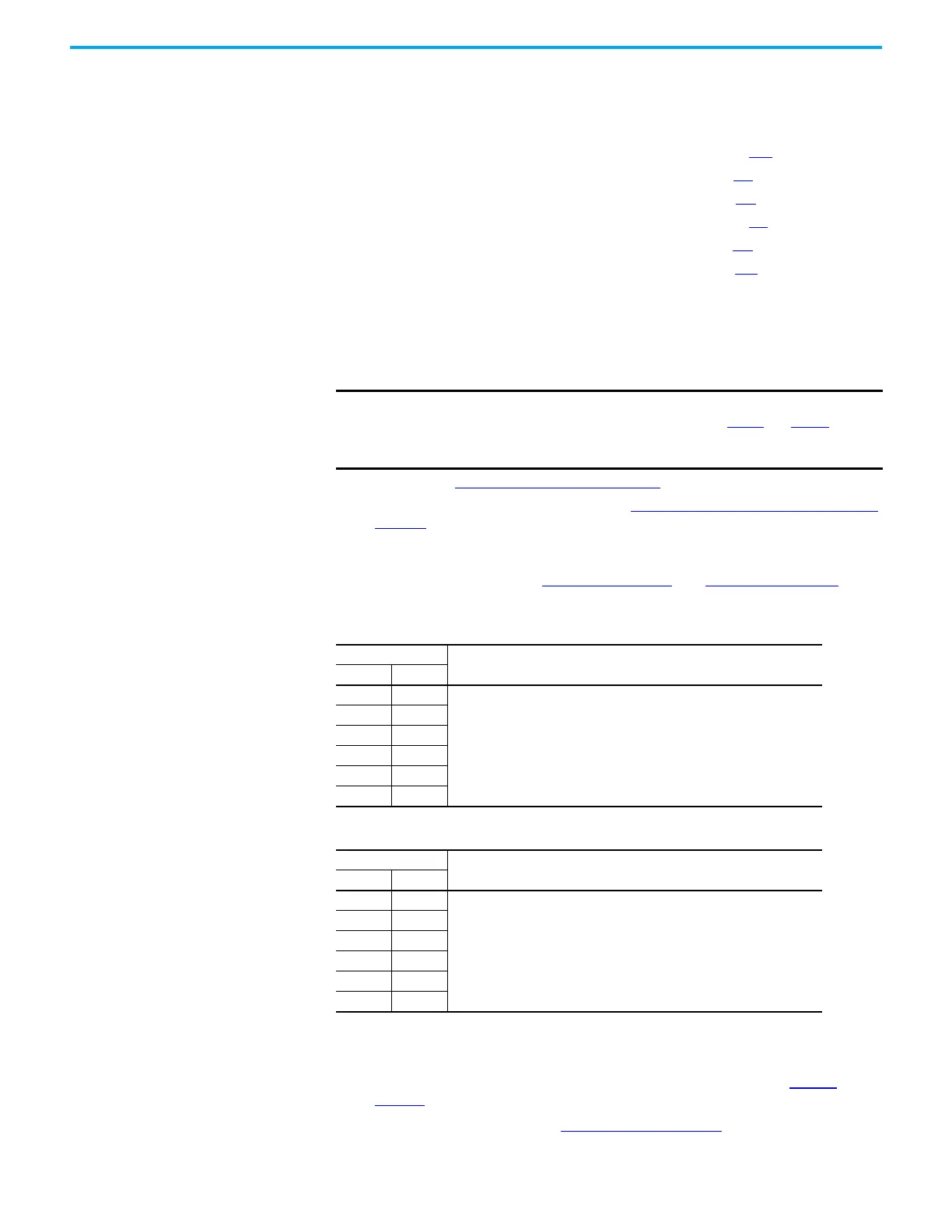

Table 1 - Forward Biased Diode Tests on the Converter IGBT Assembly

Meter Leads

Nominal Meter Reading

+-

–DC U/T1

0.36V

–DC V/T2

–DC W/T3

U/T1 +DC

V/T2 +DC

W/T3 +DC

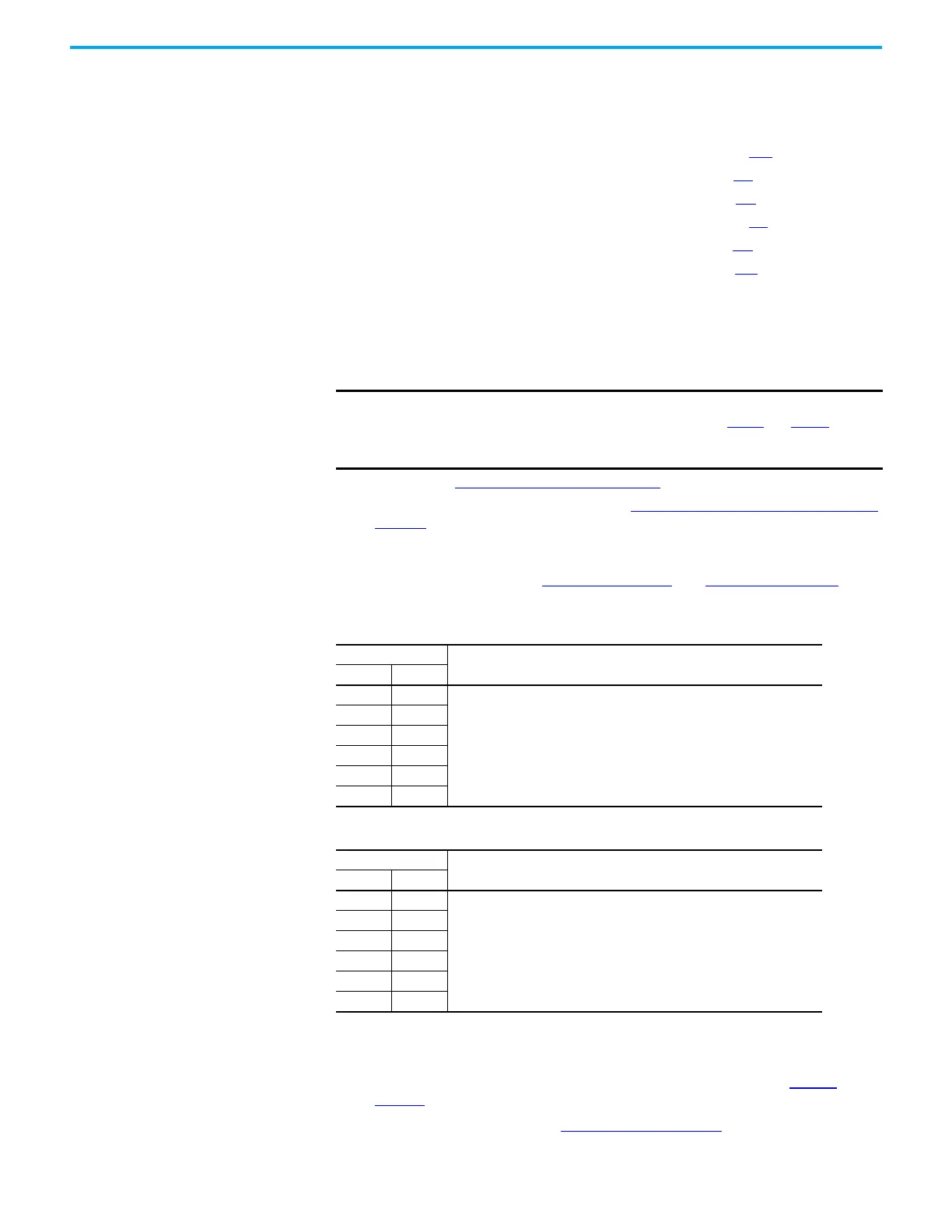

Table 2 - Reverse Biased Diode Tests on the Converter IGBT Assembly

Meter Leads

Nominal Meter Reading

+–

U/T1 –DC

“.0L” (open circuit)

(1)

(1) Residual voltage on the DC bus capacitors can affect this reading. If the capacitors are discharged (less than 1 volt),

the meter initially shows a low voltage. This voltage reading is the residual bus voltage plus the drop through the low

side diodes. The meter gradually charges the bus, and the voltage slowly increases, until eventually the meter

switches to “.OL”. This increase can take several minutes to occur.

V/T2 –DC

W/T3 –DC

+DC U/T1

+DC V/T2

+DC W/T3

Loading...

Loading...