Rockwell Automation Publication 750-TG101A-EN-P - June 2022 73

Chapter 4 Frames 1…5 Renewal Kits Installation

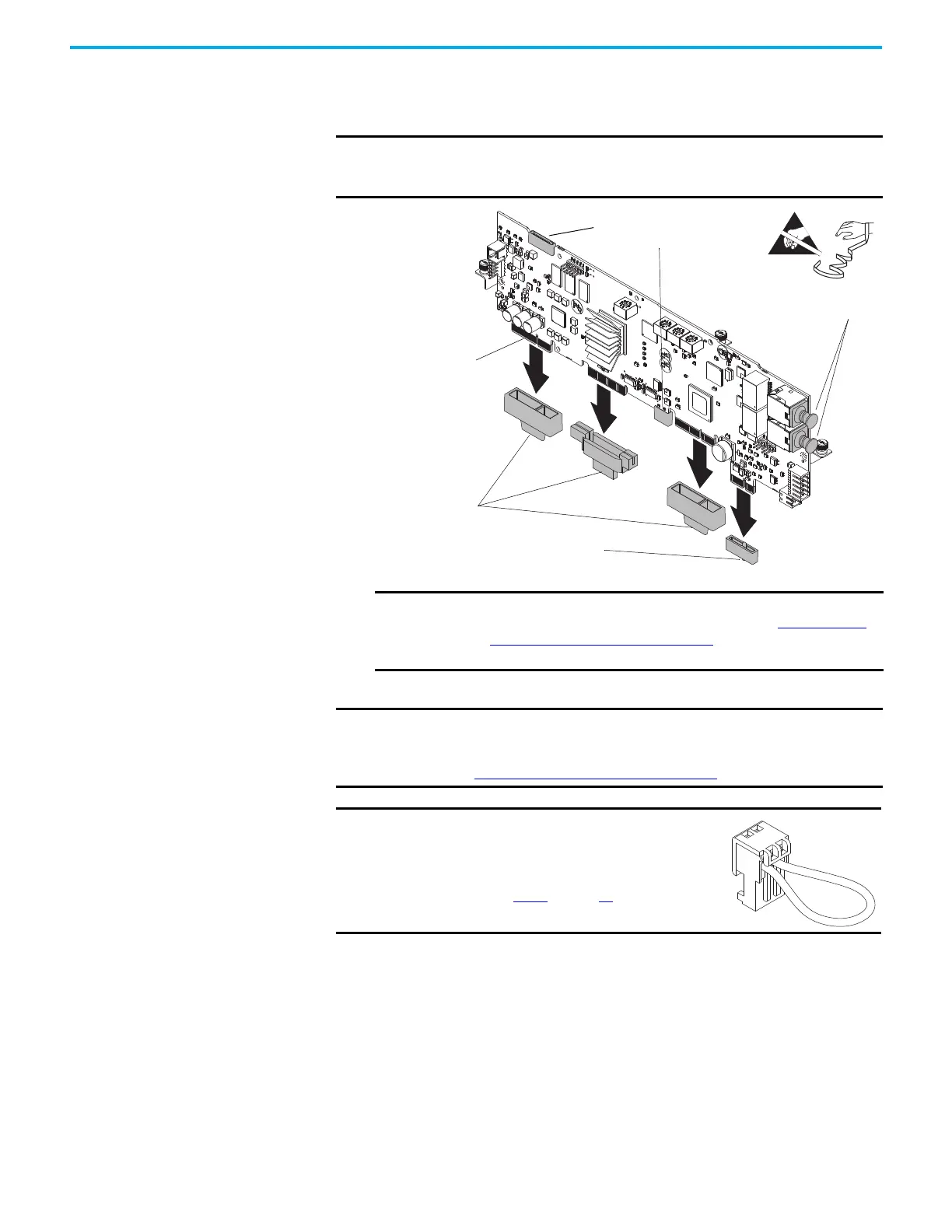

1. For kit catalog number SK-RT-MCB1-PF755-XT only, hold the tab on the

protective cover and carefully remove the cover from the edge connector

on the circuit board. Do not touch the edge connector.

2. Install the main control circuit board in the reverse order of removal.

3. Make any necessary changes to the settings on these main control board

selectors or jumpers:

• Control switch

• Embedded EtherNet/IP address switches

• Hardware enable jumper

• Safety enable jumper

IMPORTANT If a Torque Accuracy Module (TAM) is not installed, do not remove the

protective cover from the edge connector that is identified in the

illustration.

IMPORTANT If before installation, grease is removed from an edge connector or

is contaminated, do not install the circuit board. See Apply Dielectric

Grease to an Edge Connector on page 18 for instructions on how to

clean and grease an edge connector.

IMPORTANT Do not remove protective covers unless used at the time of installation. For

the product to meet the corrosive atmosphere rating, protective covers

must remain installed in unused connectors during storage and operation.

See Protective Covers on Kits with XT

on page 16 for details.

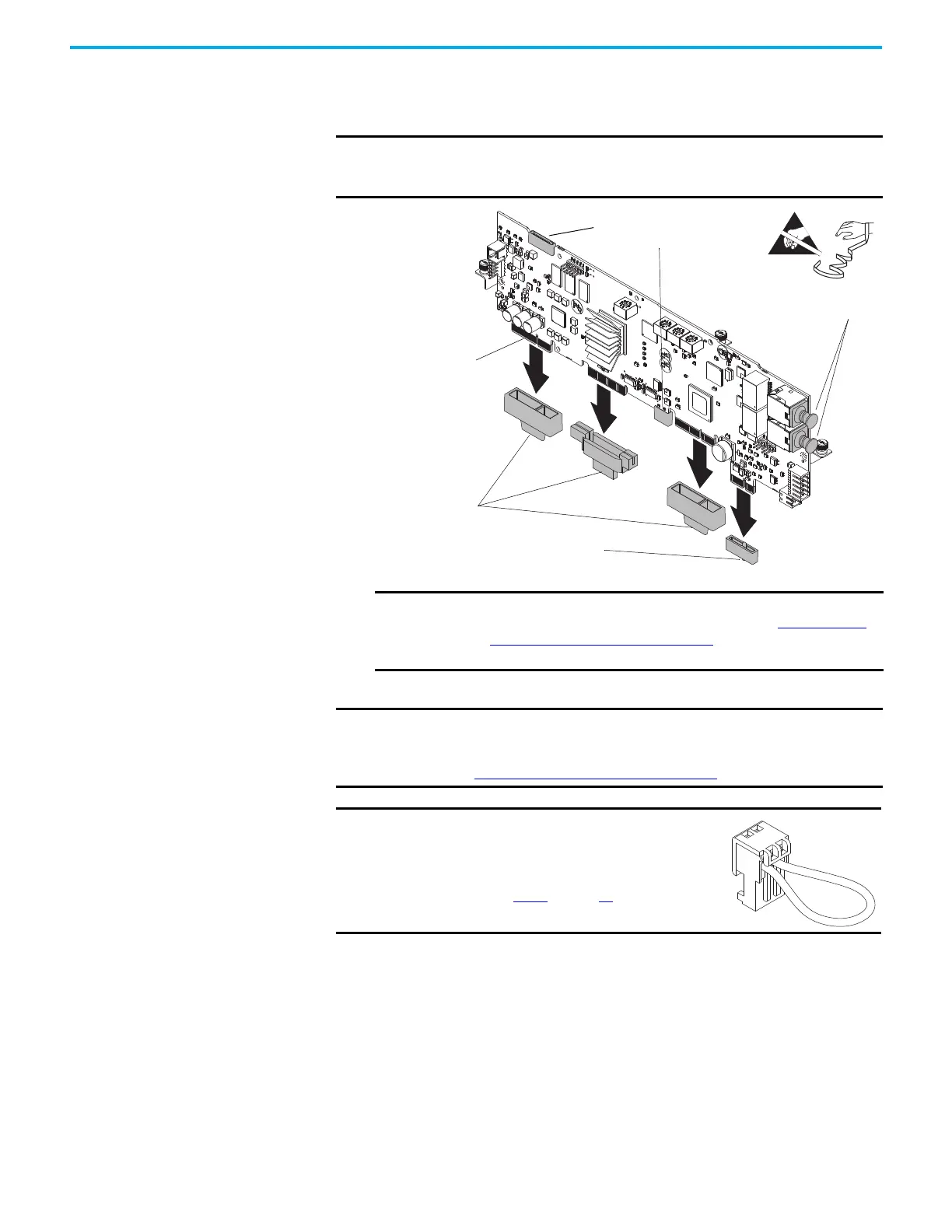

IMPORTANT

For frames 4 and 5, IP54, NEMA/UL Type 12

drives only, be sure to install jumper J16 into

connector P16 on the main control circuit

board. See step 8

on page 65 for details.

Hold Protective Cover by Tab.

Remove Only when Used

Dielectric Grease on Connectors

(Grease is Translucent - Shown

Shaded for Example Only)

Main Control Circuit Board Shown

Remove Only when a Torque

Accuracy Module is Installed.

Do Not Remove these Protective Covers

(for Factory User Only).

Remove Only when EtherNet/IP™

Cables are Installed.

Loading...

Loading...