2-3

Level Controller Overview and Installation

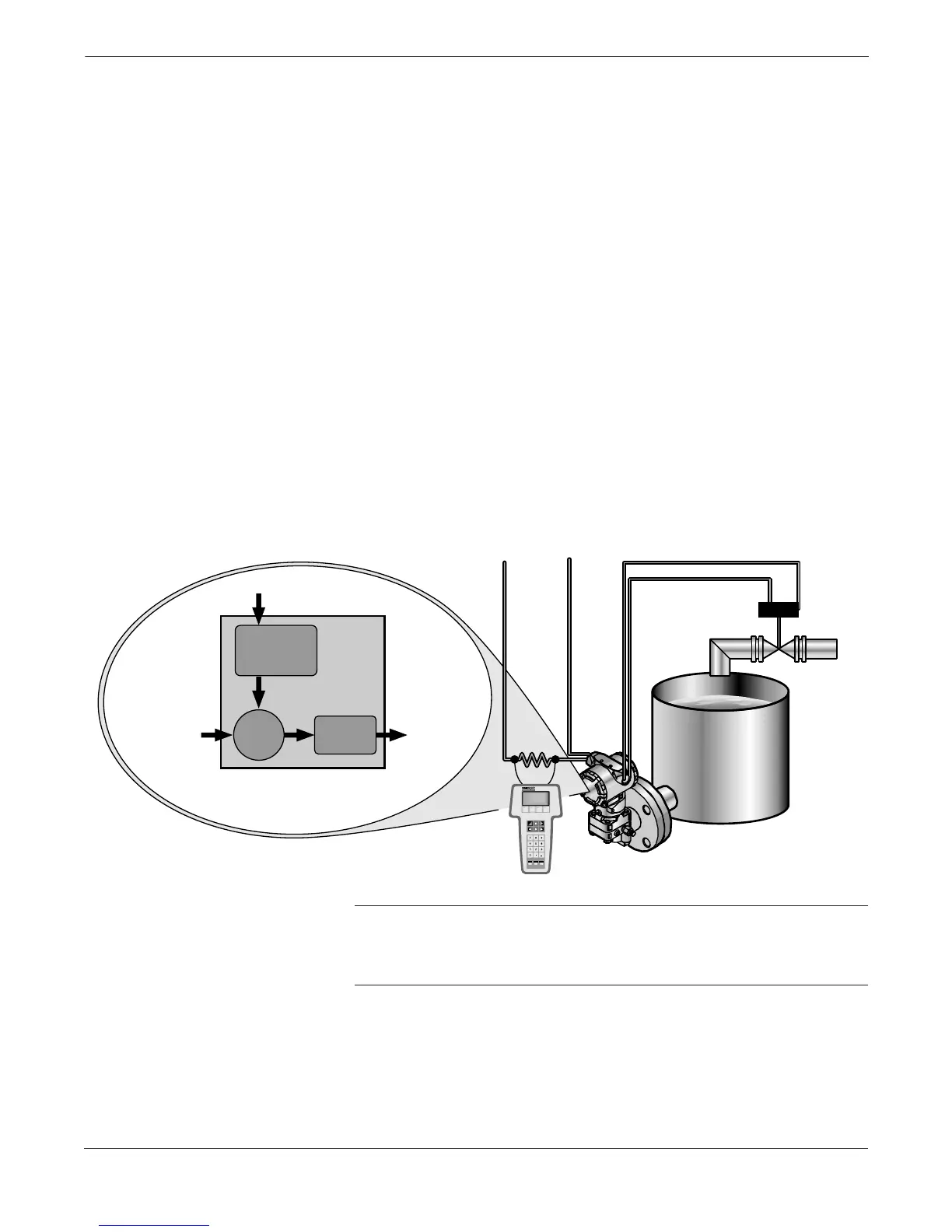

Figure 2-1 illustrates a single loop level control system. The single

control loop consists of:

• A level process.

• A Level Controller with a 4–20 mA control output signal.

• An electrical-to-pneumatic converting device such as a 3311 I/P.

• An optional positioner device to correct for valve displacement

before valve variations affect the process.

• An actuator device such as a valve.

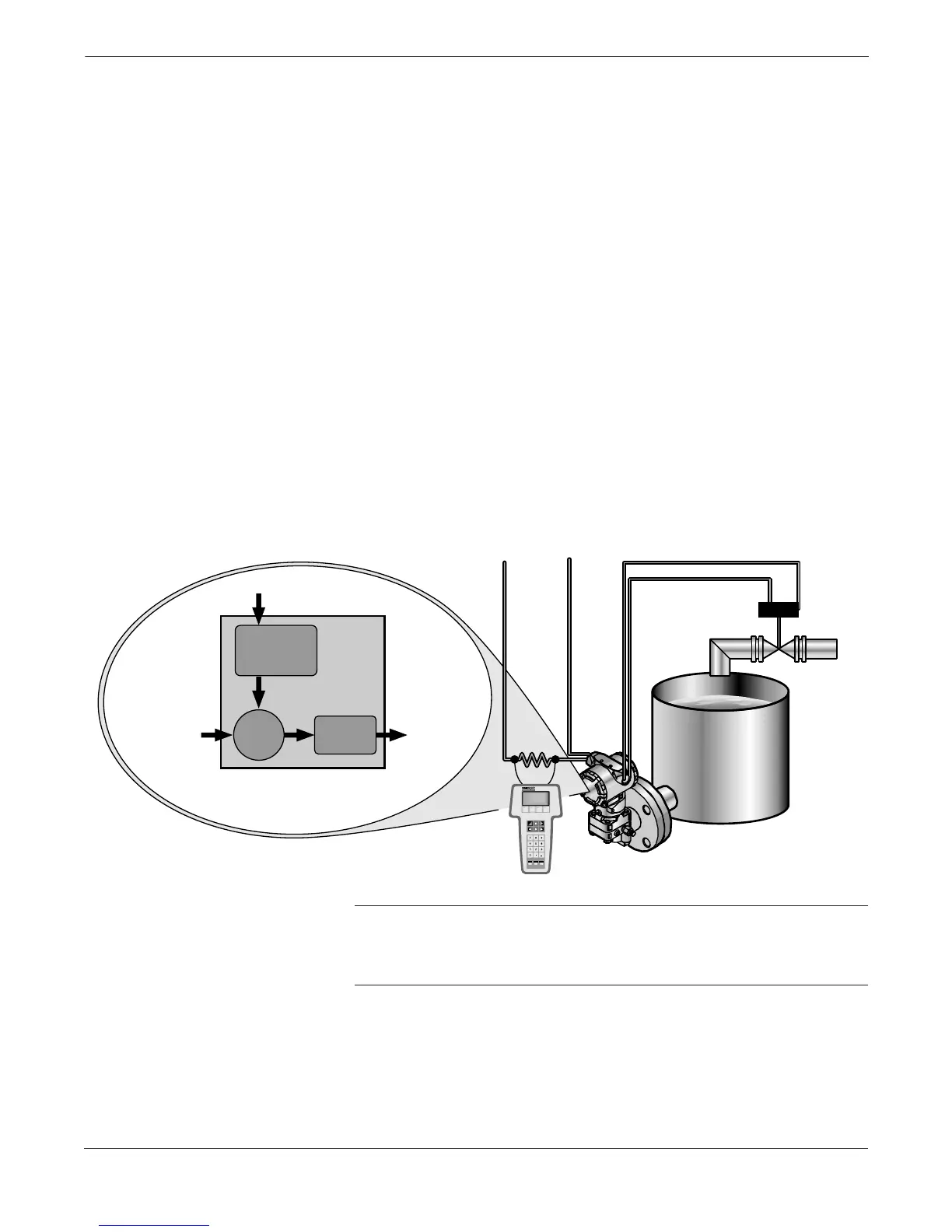

Figure 2-2 is a more detailed diagram of the level process depicted in

Figure 2-1. The setpoint is the desired process value at which the user

wishes to maintain (control) the process. The error between the setpoint

and the actual process variable (as measured by the sensor) is used by

the controller to determine the value of its output.

The controller output is an electrical current (in mA) which is used by

an electrical-to-pneumatic device, such as an I/P, to control the position

of a valve. A positioner, which is mechanically connected to the moving

part of the valve, automatically adjusts its output pressure in order to

maintain a desired position that bears a predetermined relationship to

the input signal.

FIGURE 2-2. Level Controller

Process Diagram

NOTE

The Level Controller differs from a standard transmitter in

that the 4–20 mA output is a control output, not a differential

pressure (DP) output.

3095\3095_10A

SETPOINT

Level Target

Tank

Level

PID

4–20 mA

Valve

Position

Loading...

Loading...