2-17

Level Controller Overview and Installation

Process Considerations

Level Controller process connections on the controller flange are ¼–18

NPT. Flange adapter unions with ½–14 NPT connections are available as

options. These are Class 2 threads; use your plant-approved lubricant or

sealant when making the process connections. The process connections

on the controller flange are on 2

1

/8-inch (54-mm) centers to allow direct

mounting to a three- or five-valve manifold. By rotating one or both of

the flange adapters, connection centers of 2, 2

1

/8, or 2¼ inches (51, 54,

or 57 mm) may be obtained.

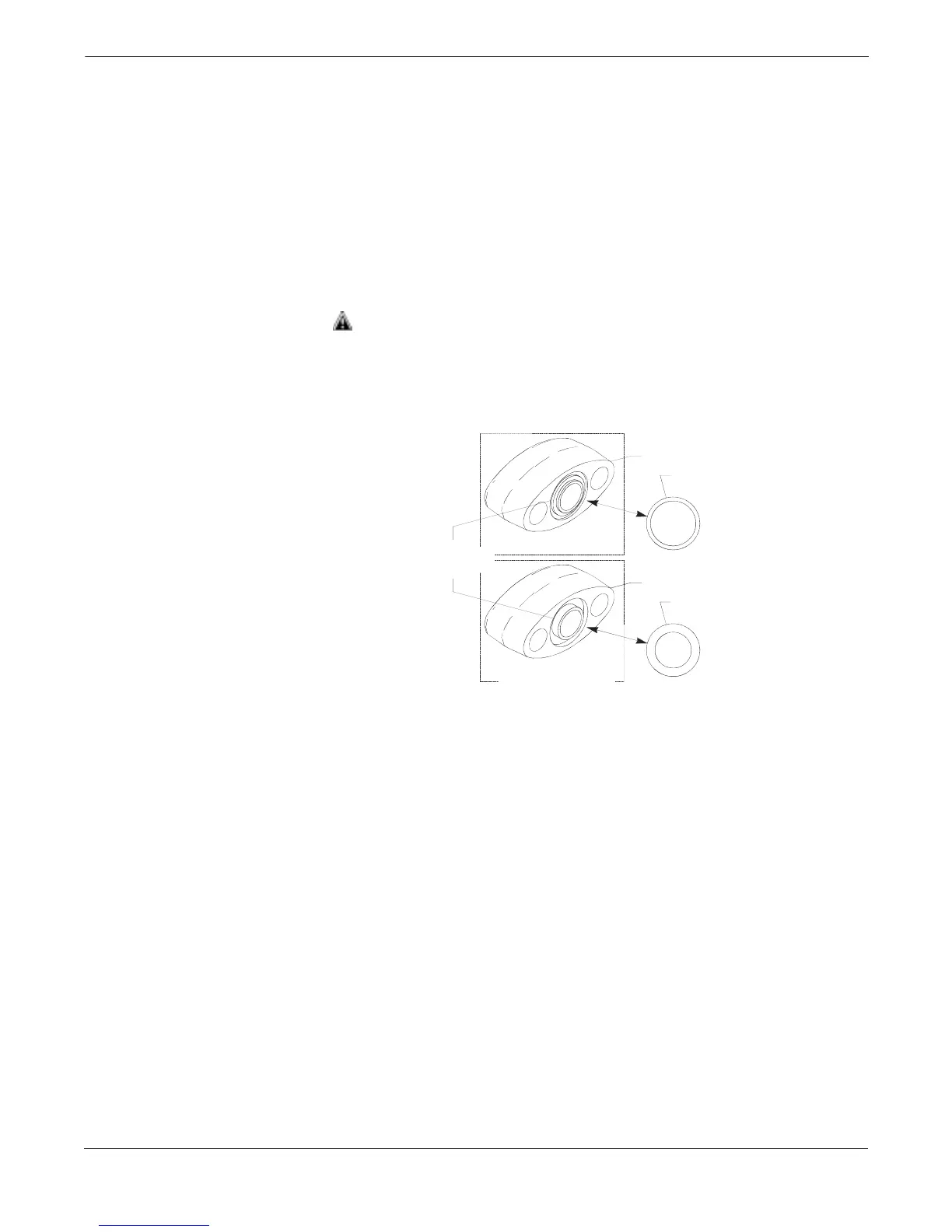

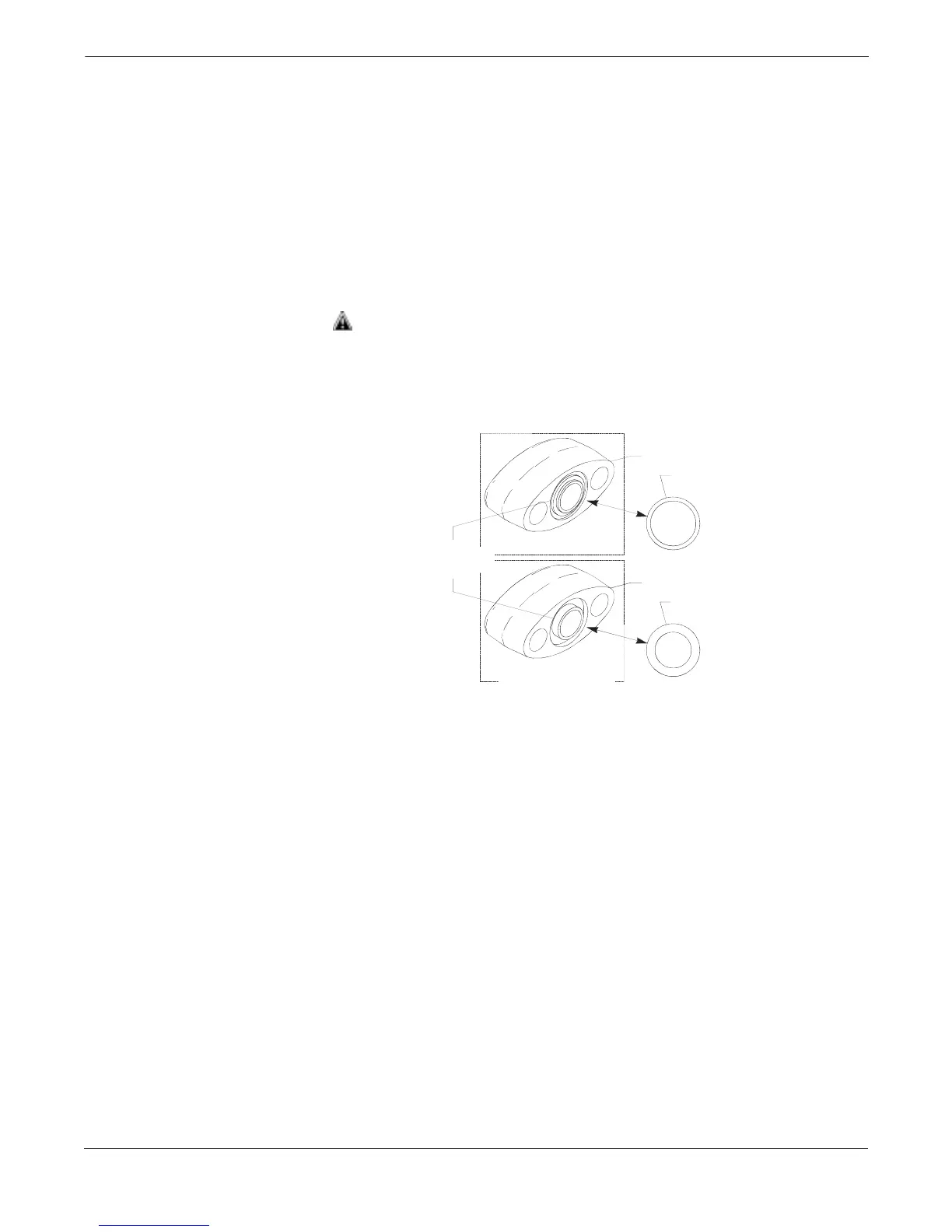

There are two styles of Rosemount flange adapters, each requiring a

unique O-ring, as shown below. Each flange adapter is distinguished

by its unique groove. Use only the O-ring designed to seal with the

corresponding flange adapter.

Use only the O-ring designed to seal with the corresponding flange

adapter. Failure to install proper flange adapter O-rings can cause

process leaks.

FIGURE 2-10. Flange Adapter O-rings.

When compressed, Teflon

®

O-rings tend to cold flow, which aids in their

sealing capabilities. Whenever flanges or adapters are removed, visually

inspect the Teflon O-rings. Replace them if there are any signs of

damage, such as nicks or cuts. If they are undamaged, they can be

reused. If the O-rings are replaced, the flange bolts may need to be

retorqued after installation to compensate for cold flow. Refer to the

process sensor body reassembly procedure on page 5-16.

Unique O-ring

Grooves

MODEL 3051/2024/3001/3095/Level Controller

MODEL 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

3051-0569A01A

Loading...

Loading...