5-3

Troubleshooting and Maintenance

Interpreting Level

Controller Alarms and

Error Conditions

If an alarm or error condition exists in the Level Controller, it will be

displayed when the next Model 275 next communicates with the device.

Table 5-2 explains critical alarms, Table 5-3 lists overrange conditions,

and Table 5-4 identifies sensor limits.

Critical Alarms Critical alarms are the highest priority Level Controller alarms, and

typically indicate an error that prevents accurate sensor or flow

measurements. Regardless of which of these alarms occur, the analog

output and the digital output respond as indicated in Table 5-2.

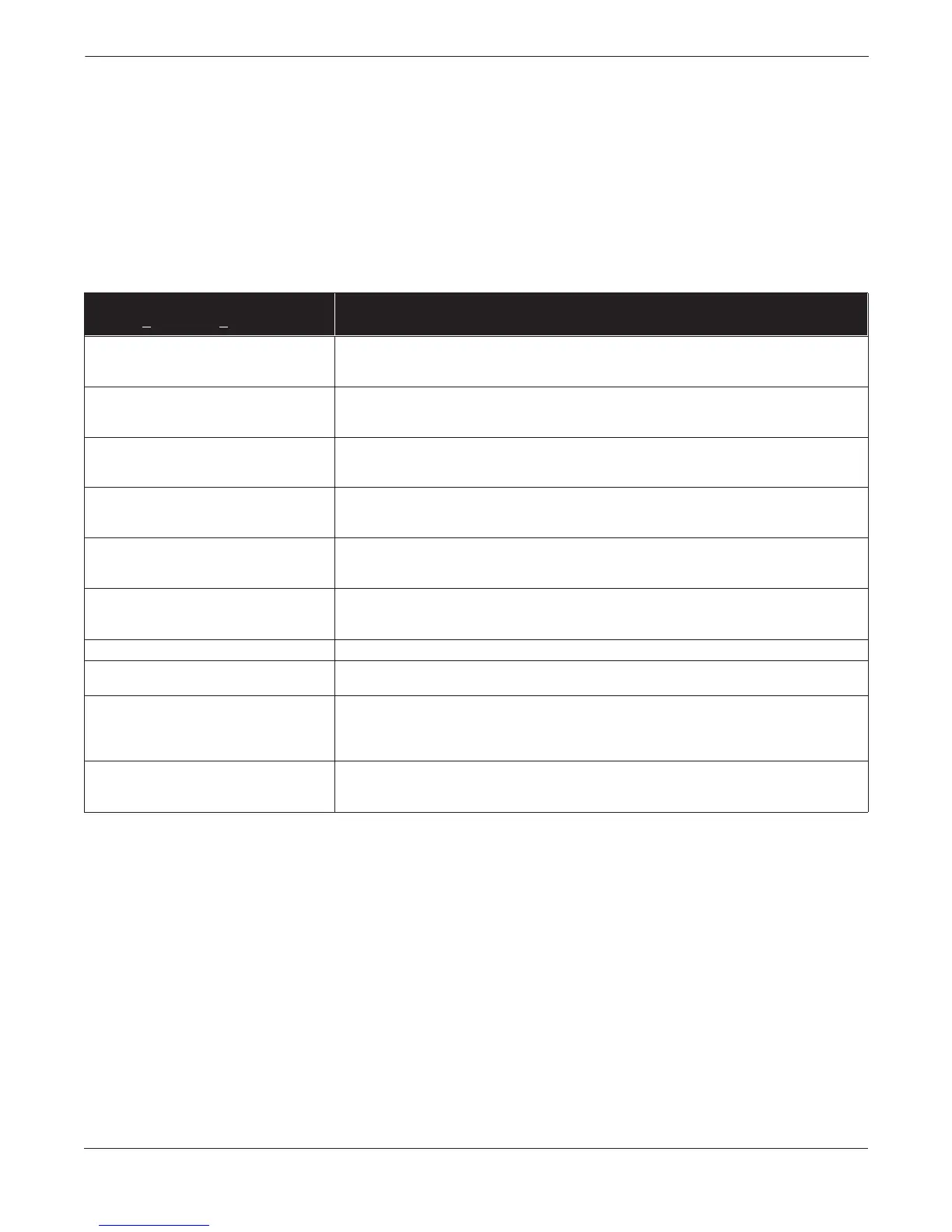

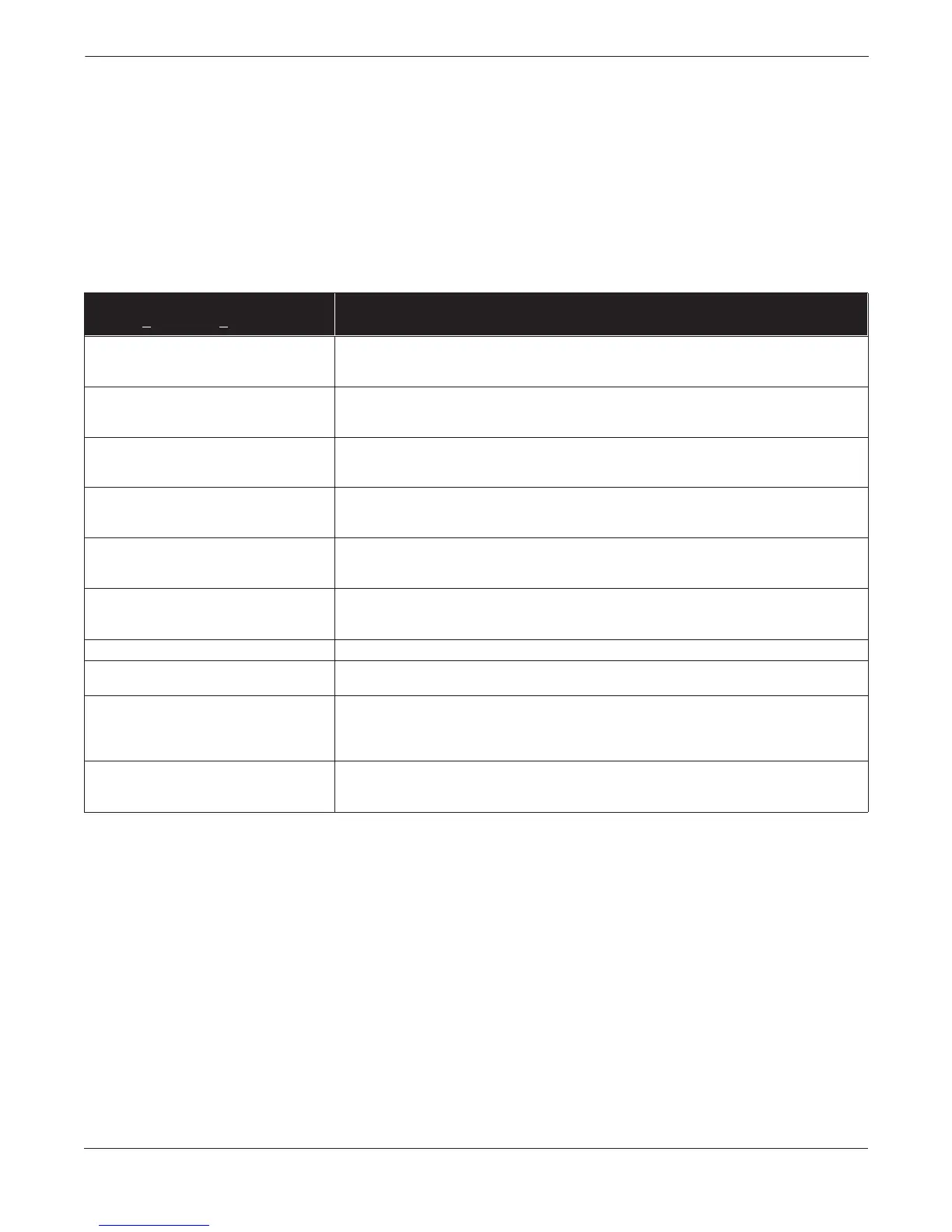

TABLE 5-2. Critical Alarms.

Alarm text as displayed in

D

iagnostics, Error Info

Corrective Action

Output Board EEPROM Not Initialized

Output Board EEPROM Burn Failure

The output electronics has not been properly initialized at the factory. Replace the output electronics

board as described on page 5-11.

Contact your Field Service Center.

Sensor Hardware is Incompatible The sensor electronics has undergone a component or software failure. Replace the sensor module

as described on page 5-11.

Contact your Field Service Center.

Sensor Brd EEPROM Not Initialized The sensor electronics has undergone a component or software failure. Replace the sensor module

as described on page 5-11.

Contact your Field Service Center.

Sensor Module is Not Updating The 10-pin ribbon cable may be disconnected, or the device electronics may have undergone a

component or software failure.

Contact your Field Service Center.

Sensor Module is Not Responding The 10-pin ribbon cable may be disconnected, or the device electronics may have undergone a

component or software failure.

Contact your Field Service Center.

Static Pressure Sensor is Shorted The sensor module has undergone a component or software failure. Replace the sensor module as

described on page 5-11.

Contact your Field Service Center.

RAM Failure Issue a master reset to the device.

Device Self Test Failed The output electronics has undergone a component or software failure. Replace the output

electronics board as described on page 5-11.

Static Pressure Sensor is Open This display means that the device absolute pressure reading exceeds its sensor limits. There are two

possible causes. Either the device is overpressured, or it has a sensor malfunction. Check the

pressure input to the device. If an overpressure condition exists, correct it. If not, replace the sensor

module as described on page 5-11.

Process Temp Sensor is Disconnected Check the device RTD connector and RTD screw terminals to ensure the RTD cable is properly

connected. For controller installations not using the RTD option, make certain the RTD option is set

to “Not Installed.”

Loading...

Loading...