5-7

Troubleshooting and Maintenance

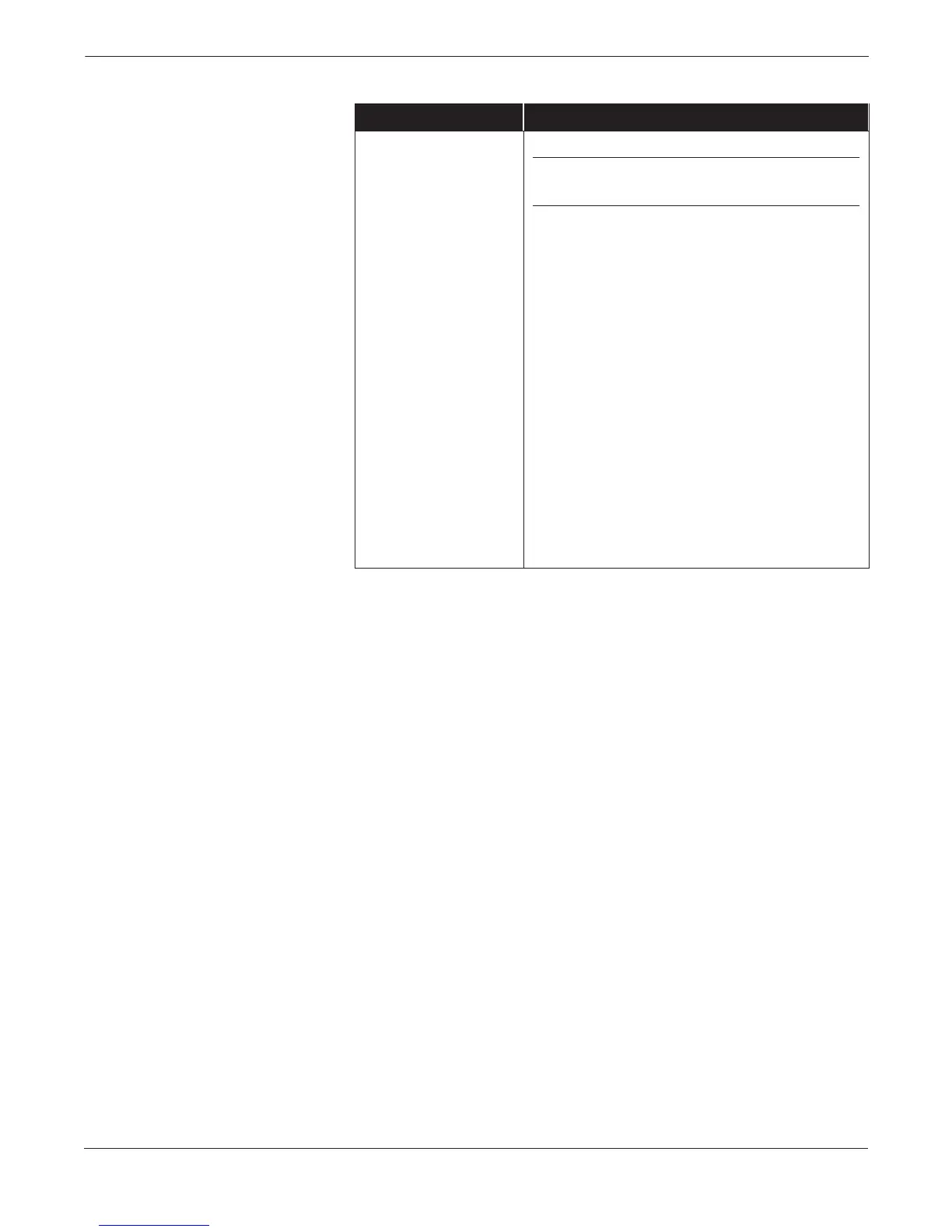

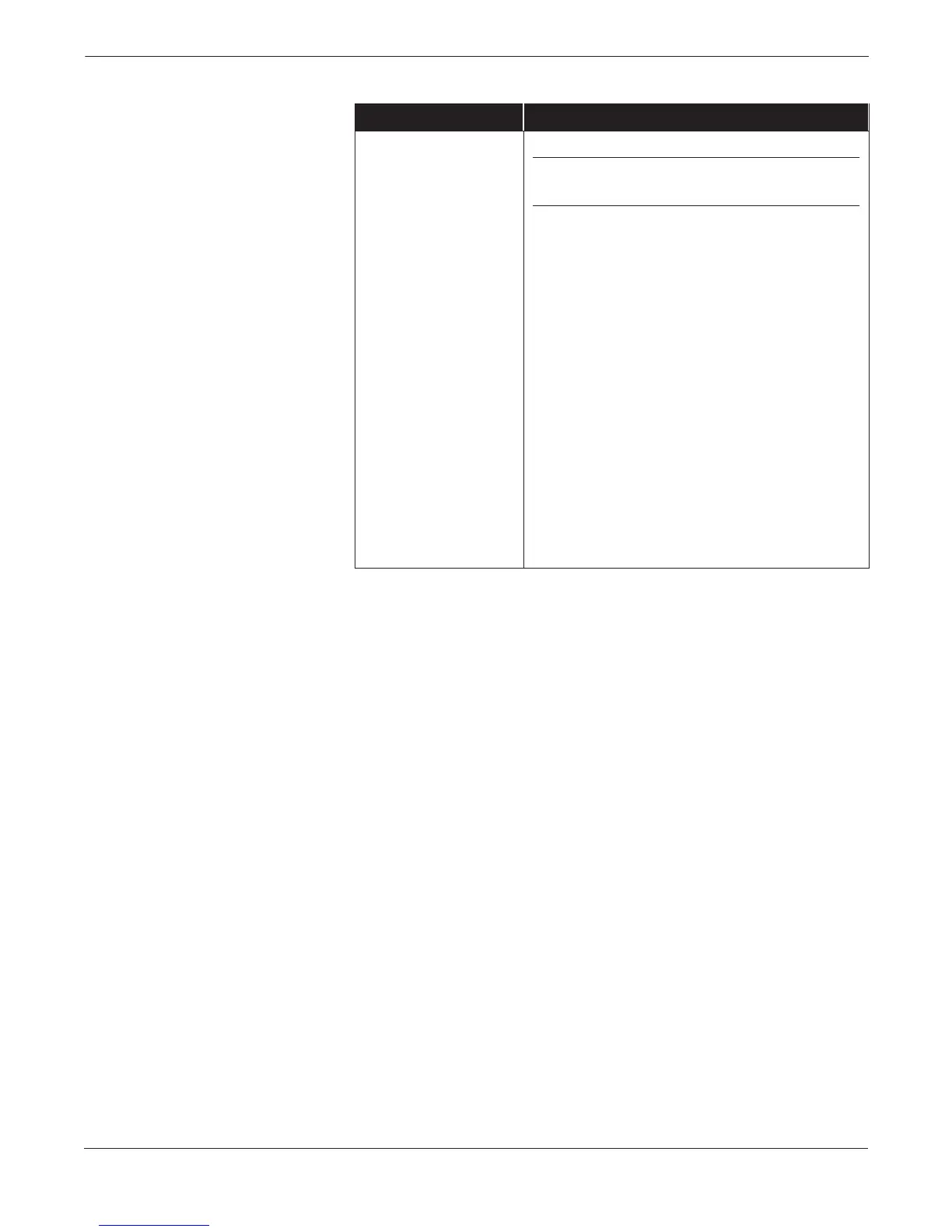

TABLE 5-5. (continued).

Symptom Corrective Action

Erratic PV Reading LOOP WIRING

CAUTION

Do not use higher than the specified voltage to check the loop

or damage to the device may result.

• Check for adequate voltage to the device. It should be

11 to 55 V dc at the device terminals.

• Check for intermittent shorts, open circuits, and

multiple grounds.

PROCESS PULSATION

• Adjust the electronic damping (see page 4-4).

DEVICE ELECTRONICS

• Connect a Model 275 to check the sensor limits to ensure

calibration adjustments are within the sensor range and that

calibration is correct.

• Make sure the post connectors are clean.

• Confirm that the electronics housing is properly sealed

against moisture.

• If the electronics are still suspect, substitute new electronics.

IMPULSE PIPING

• Check for entrapped gas in liquid lines and for liquid in

gas lines.

• Make sure that process fluid has not frozen within the

process flange.

SENSING ELEMENT

• The sensing element is not field repairable and must be

replaced if found to be defective. Check for obvious defects,

such as a punctured isolating diaphragm or fill fluid loss, and

contact your nearest Rosemount Service Center.

Loading...

Loading...