SAMWONTECH

1st Edition of TEMP880S IM : Sep. 21. 2005 Page 47 / 101

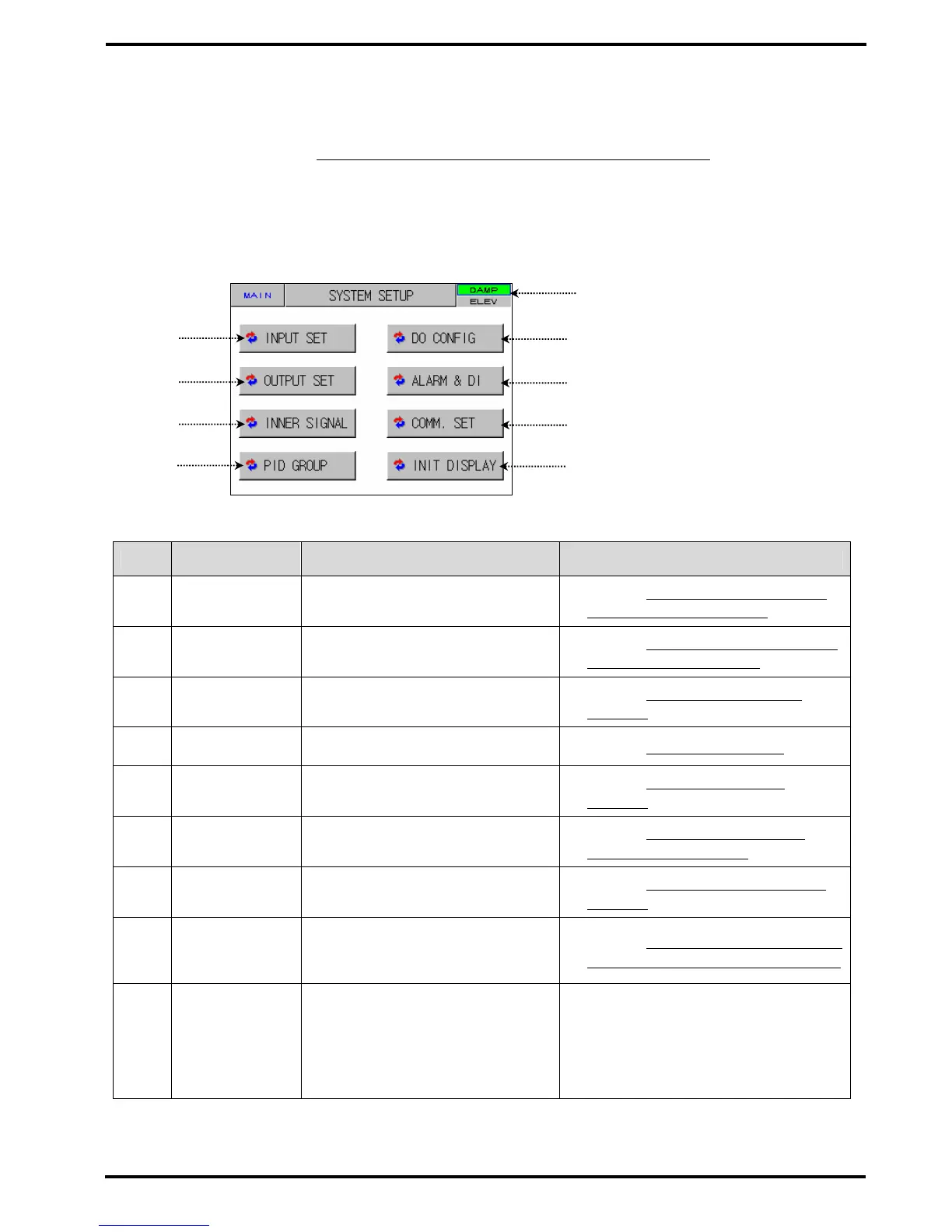

2.12 SYSTEM SETUP SCREEN

▶ Screen for initial setting for operation

▶ As it’s possible to approach without a password in case of forwarding from factory, make sure of

▶ setting a password at 2.12.8 initialization mark and condition mark lamp Setting

when it’s not

▶ necessary to block the general user.

☞ When it’s changed in a wrong way, the Setting Points within the System Setting Screen can cause a

☞ problem in operating an equipment.

Diagram 2-45. System Setup Screen

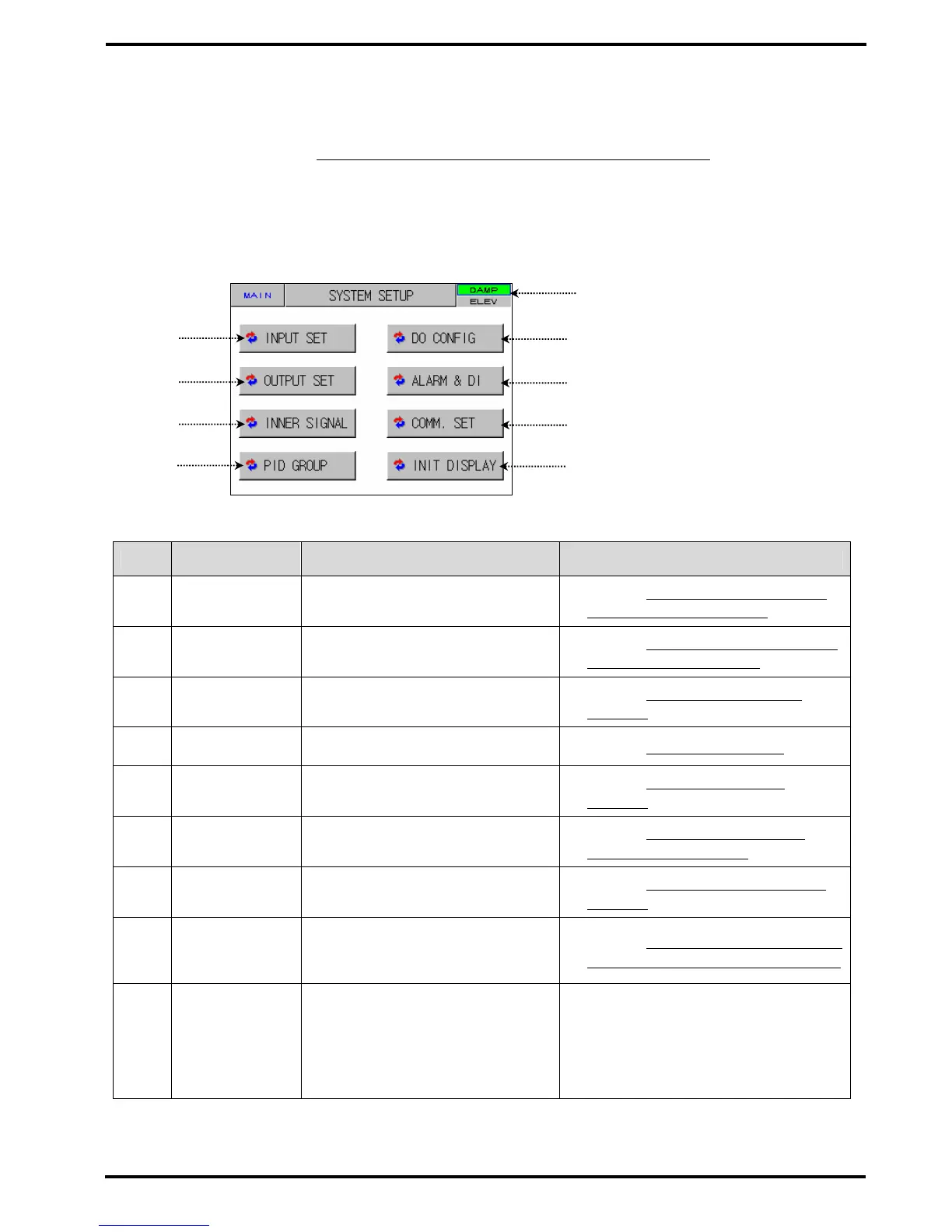

No. Instruction Contents Additional Explanation

○

1

INPUT SET

Shifts to input and input

compensation setting screen.

▶ Refer to 2.12.1 INPUT AND INPUT

▶ COMPENSATION SETTING

○

2

OUTPUT SET

Shifts to control output and

transmission setting screen.

▶ Refer to 2.12.2 Control Output AND

▶ TRANSMISSION SETTING

○

3

INNER SIGNAL

Shifts to inner signal setting

screen.

▶ Refer to 2.12.3 INNER SIGNAL

▶ SETTING

○

4

PID GROUP

Shifts to PID related setting

screen.

▶ Refer to 2.12.4 PID SETTING

○

5

DO CONFIG

Shifts to additional output setting

screen.

▶ Refer to 2.12.5 DO CONFIG

▶ SETTING

○

6

ALARM & DI Shifts to alarm DI setting screen.

▶ Refer to 2.12.6 ALARM AND DI

▶ ERROR NAME SETTING

○

7

COMM. SET

Shifts to communication related

setting screen.

▶ Refer to 2.12.7 COMMUNICATION

▶ SETTING

○

8

INIT DISPLAY

Shifts to initial screen related and

condition display lamp setting

screen.

▶ Refer to 2.12.8 INITIAL DISPLAY AND

▶ CONDITION DISPLAY LAMP SETTING

○

9

CHAMBER TYPE

Sets whether a thermal shock

tester is DAMPER TYPE or

ELEVATOR TYPE.

▶ Control zone in the first SEG during

▶ program operation when it is set to

▶ be ELEVATOR TYPE with TSP

▶ concerned.

☞ Preheating SP and precooling SP

▶ will proceed in other zone.

○

1

○

5

○

2

○

3

○

6

○

7

○

4

○

8

○

9

Loading...

Loading...