SERVICE MANUAL

\

I

i

i

80.22

Page 3

SOLID STATE STEPPER UNIT,

Type SSU4

The tabs oo

tbe release dog operatiog lioks

vhich eogage the dogs

and

couple

them to the

reset uragoet

reset

Eagoet should

not bind tigbtly

but should Dot

peroit

Eo(e thao 0.005 ioch free

travel betveeo

the dogs aod the lioks.

h. Reset Magnet

Tail

Spring

The

force applied to the end of

the teset

oagoet

araature

("2",

Figure 2) to

start

it ftom the

rest

positioo

should

be 100 to

140 gtaas

(3%

to

5

oz.).

i. Release

Dog Springs

An

upward

fcce of

15

to 25

grams

(%

rc

%

oz.)

applied at the diople

on the release dog operatiog

links

("Y",

Figure 2) should start

the dogs froo

seated

position. This

force

will

be apptoxioately

correct

if the sp,rings

are wound

Yt

to

%

trnt.

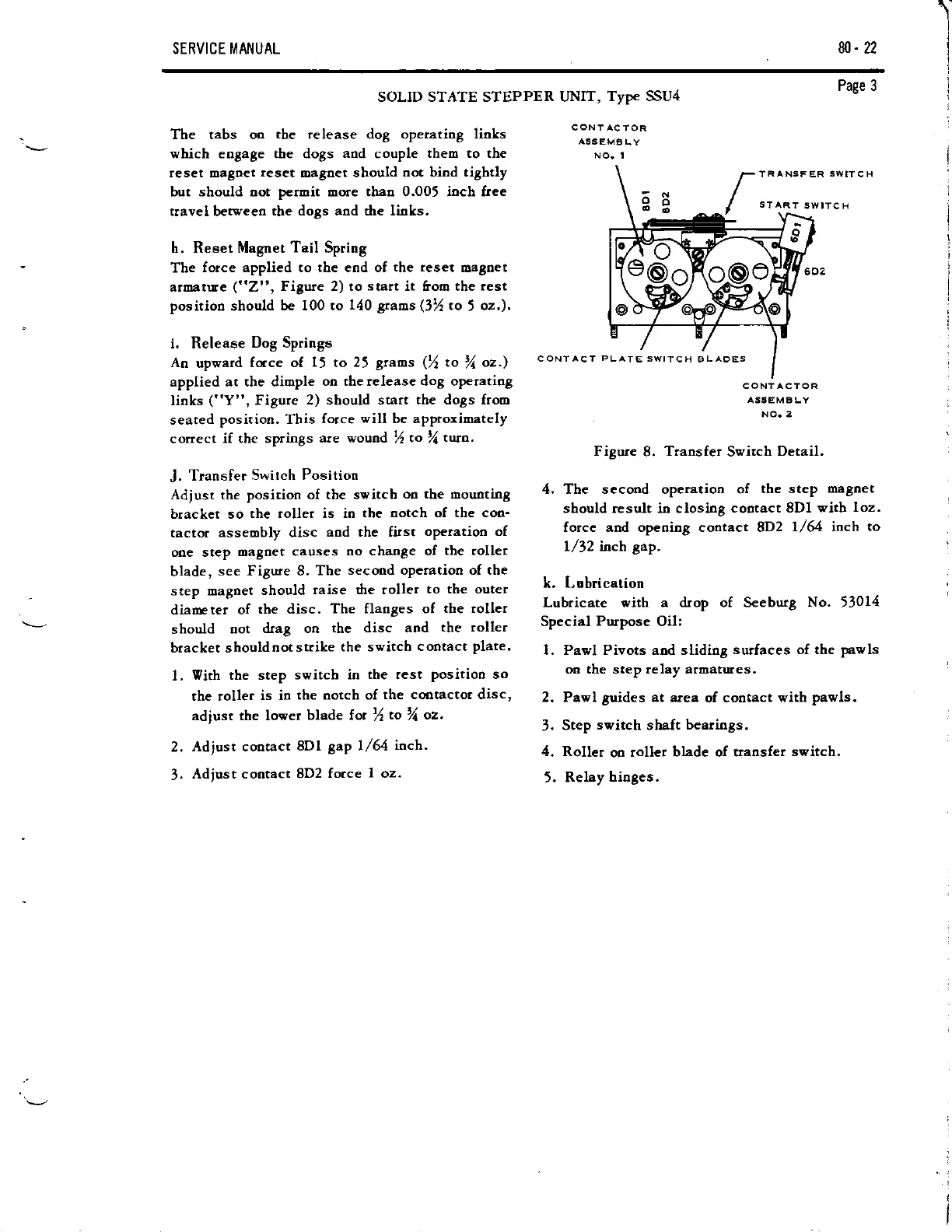

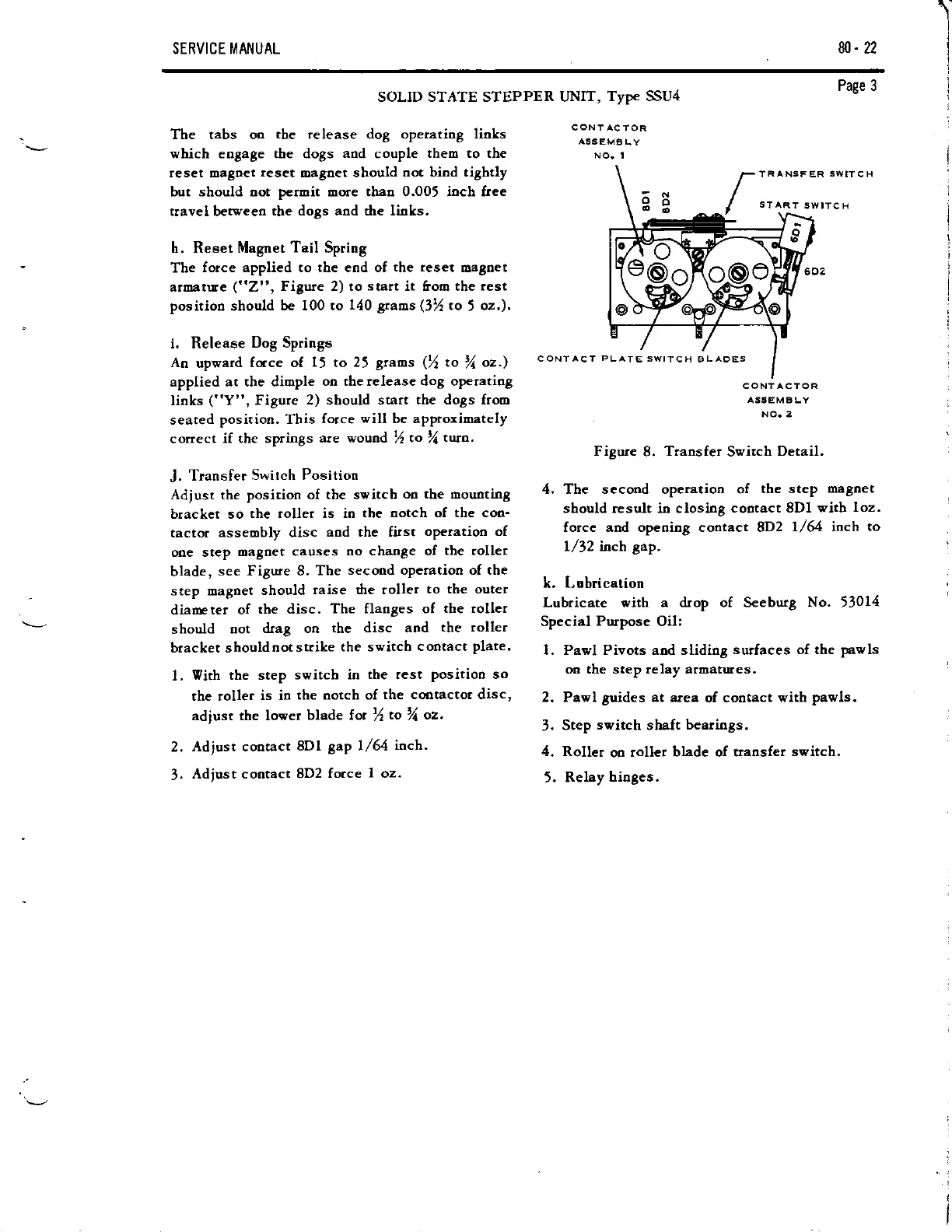

J.

Transfer

Switch Position

Adjust the

positioo

of the

svitch

oo the

mouoting

bracket so

the roller is io

tbe aotch of the coa'

tactor

asseobly disc

aod the first

oPeratioo of

one step

rlagoet causes

no chaage of

the roller

blade,

see Figure 8.

The

second oPeratioo of the

srep magnet

should

raise dre roller

to the oute!

diareter of

the disc.

The flanges of

the roller

should

oot

&ag on

the disc aud

the roller

bracket shouldnotsrike

the switch

cootact

plate.

L

Vith the step

switch in

the rest

positioo

so

the roller

is in

the notch of

the cootactor disc,

adjust the lover

blade fq

Yz

to

%

oz.

2.

Adiust contact

8Dl

gap

L/64

itch.

3.

Adjust cootact

8D2 force

I

oz.

NO. I

CONIACir

PLAT

E SWITCH BLAOES

TRANSFER

SWII

C H

^":."::"

Figure

8.

Transfer

Switch

Detail.

4. Tbe second opeetion of

the step

magnet

should tesult in closing

co[tact 8D1 with

loz.

force aod opeoinS coatact 8D2

l/64 inch

to

L/32 nch

gap.

k. Lubrication

Lubricate with a &op of Seeburg

No.

,3014

Special

Putpose

Oil:

l. Pawl Pivots and slidiog

surfaces of the

Pawls

oq the step relay arEatules.

2. Pawl

guides

at area

of coltact

with

pawls.

3,

Step

switch

shaft

bearings.

4. Roller

oo

roller blade of traosfer

switch.

5.

Relay

hiages.

Loading...

Loading...