Fault Finding

______________________________________________________________________________

MillipaK PUMP Controller Manual Page 43 07/11/05

Fault Clearance

Any fault indication will be cleared by re-initiating the start sequence after the cause of the fault

has been removed. Some faults may only be cleared by re-cycling the key-switch.

Using Status and Test Menus

The status and test menus which are available on the calibrator interface can be used to help

pinpoint wiring faults or device failures.

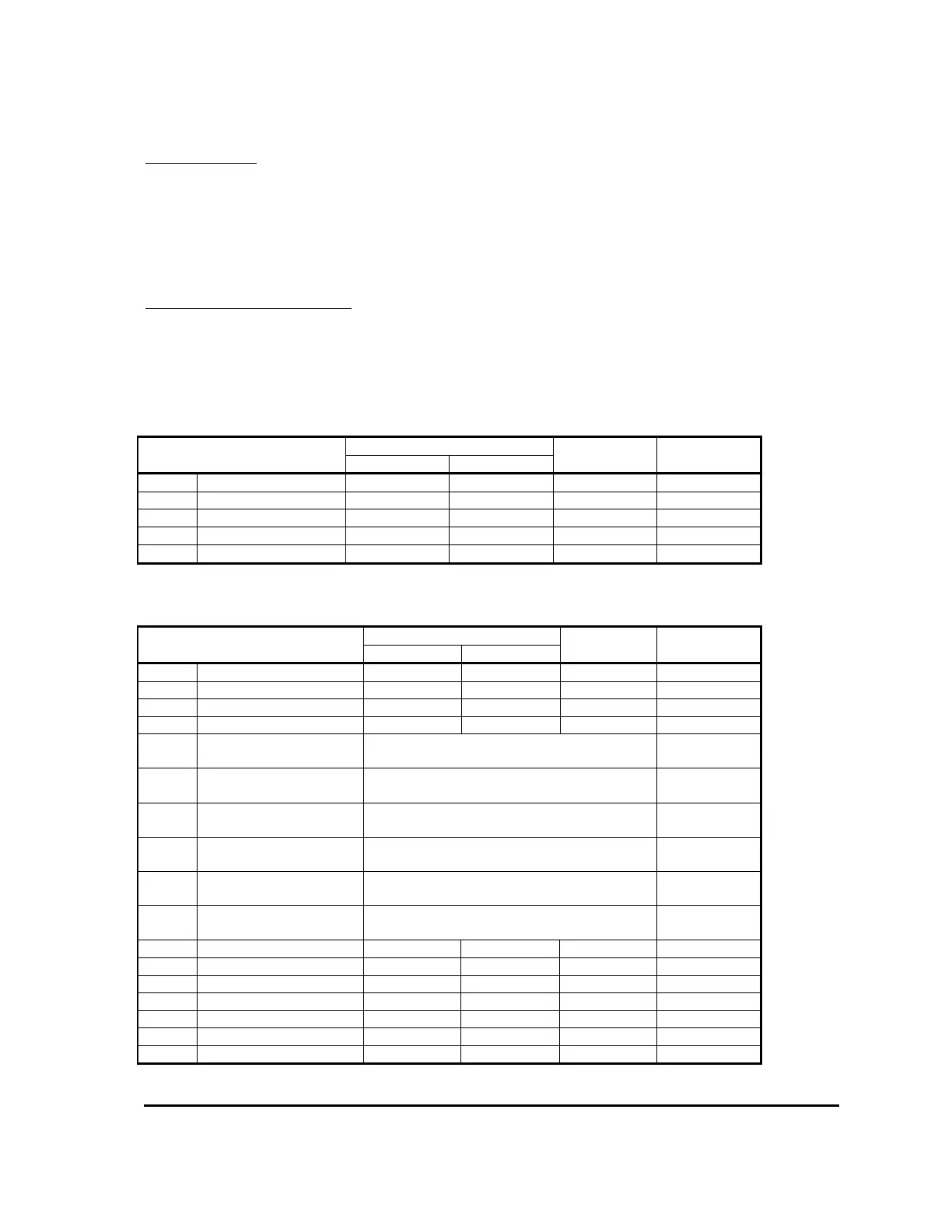

System voltages and currents are available on the following menu items:

Item Range Resolution Display

Minimum Maximum Format

15.01 Battery Voltage 0.0V 63.9V 0.1V

000.0

15.02 Capacitor Voltage 0.0V 63.9V 0.1V

000.0

16.01 Motor Voltage 0.0V 63.9V 0.1V

000.0

17.01 Motor Current 0A 1000A 5A

x000

18.01 Temperature

-30°C 225°C 1°C

x000

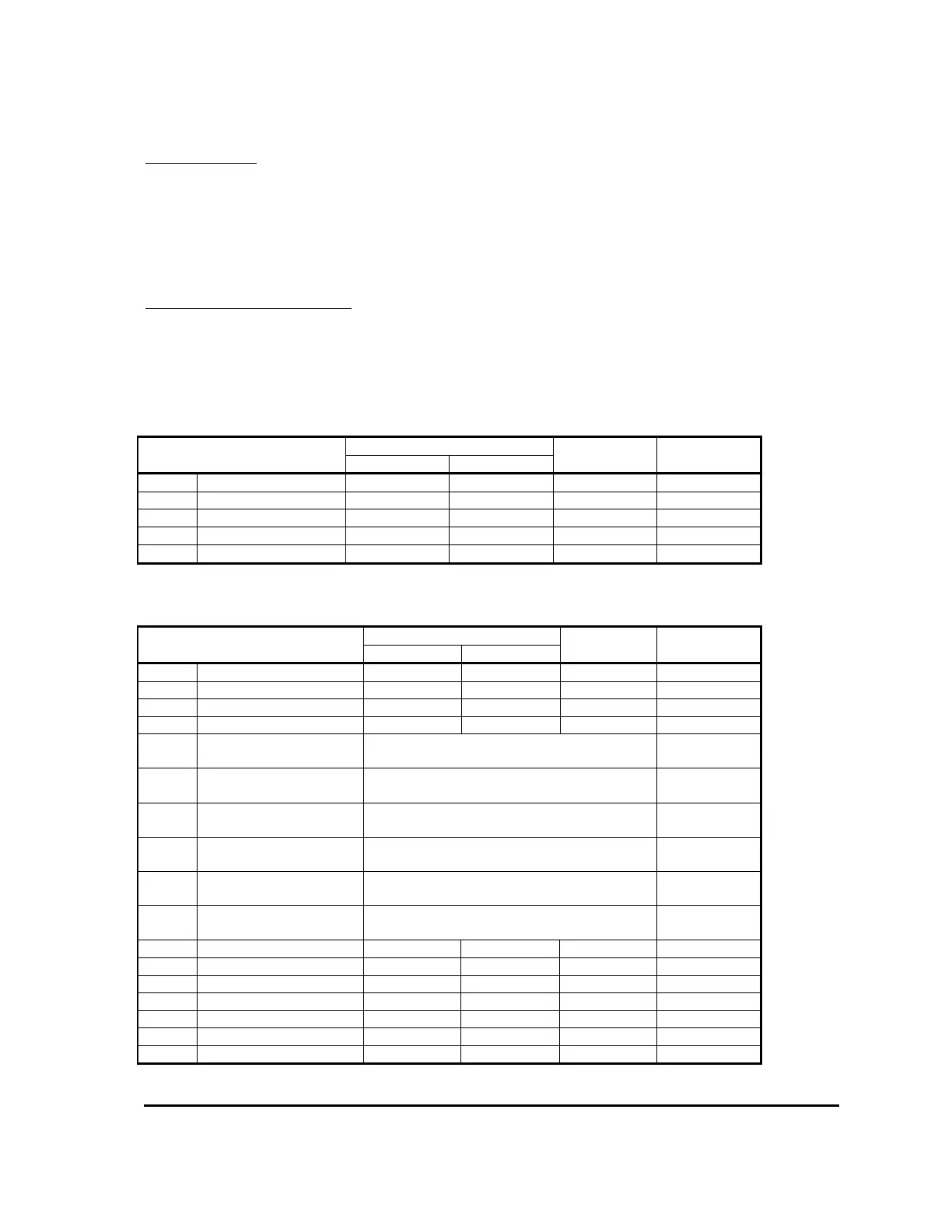

Controller analogue and digital input status can be read from the following menu items:

Item Range Resolution Display

Minimum Maximum Format

19.01 Accel 1 Demand 0% 100% 1%

x000

19.02 Accel 1 Voltage 0.00V 5.00V 0.02V

00.00

19.03 Accel 2 Demand 0% 100% 1%

x000

19.04 Accel 2 Voltage 0.00V 5.00V 0.02V

00.00

19.05 Digital 1 (Pin 2) Open

Closed

x1.OP

x1.CL

19.06 Digital 2 (Pin 3) Open

Closed

x2.OP

x2.CL

19.07 Digital 3 (Pin 4) Open

Closed

x3.OP

x3.CL

19.08 Digital 4 (Pin 5) Open

Closed

x4.OP

x4.CL

19.09 Digital 5 (Pin 6) Open

Closed

x5.OP

x5.CL

19.10 Digital 6 (Pin 7 (switch)

or Pin 11 (analogue))

4

Open

Closed

x6.OP

x6.CL

19.11 S/W Version 00.00 19.99 0.01

00.00

19.12 S/W Sub-Revision 00 99 1

xx00

19.13 SN Date Code 0100 1299 1

0000

19.14 SN ID 1 00 99 1

xx00

19.15 SN ID 2 00 99 1

xx00

19.16 Pers Checksum 0 255 1

000

19.17 System State 0 13 1

x00

Loading...

Loading...