Note

Inspection specications

• Carefully comply with the relubrication intervals for rolling bearings that deviate from the

inspection intervals.

• When servicing a three-phase machine, it is generally not necessary to dismantle it. The

machine only has to be dismantled if the bearings are to be replaced.

9.3.3 First inspection after installation or repair

Perform the following checks after approximately 500 operating hours or at the latest six

months after commissioning:

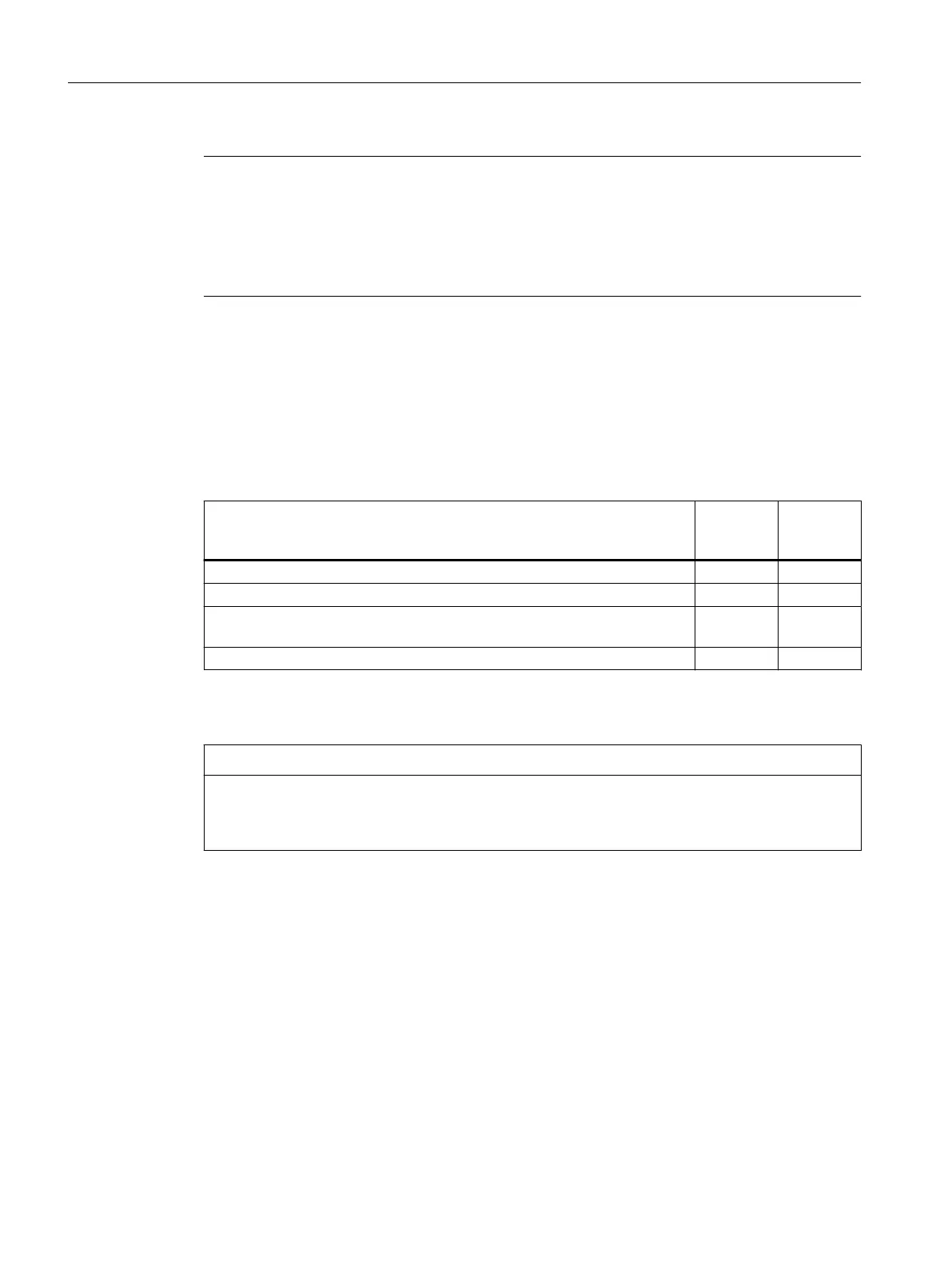

Table 9-1 Checks after assembly or repair

Checking When the

motor is

running

At stand‐

still

The electrical parameters are maintained. X

The permissible bearing and winding temperatures are not exceeded. X

The smooth running characteristics and machine running noise have not de‐

teriorated.

X

The foundation has no cracks or indentations. (*) X X

(*) You can perform these checks while the motor is running or at a standstill.

Additional tests may also be required according to the system-specic conditions.

NOTICE

Machine damage

When carrying out the inspection, if you detect any impermissible deviations from the normal

state, you must rectify them immediately. They may otherwise cause damage to the machine.

See also

Setpoint values for monitoring the bearing temperature (Page81)

Maintenance

9.3Inspection and maintenance

1LE1, 1FP1/3, 1PC1/3 shaft height 63 ... 315

98 Operating Instructions, 11/2023, A5E38483075A

Loading...

Loading...