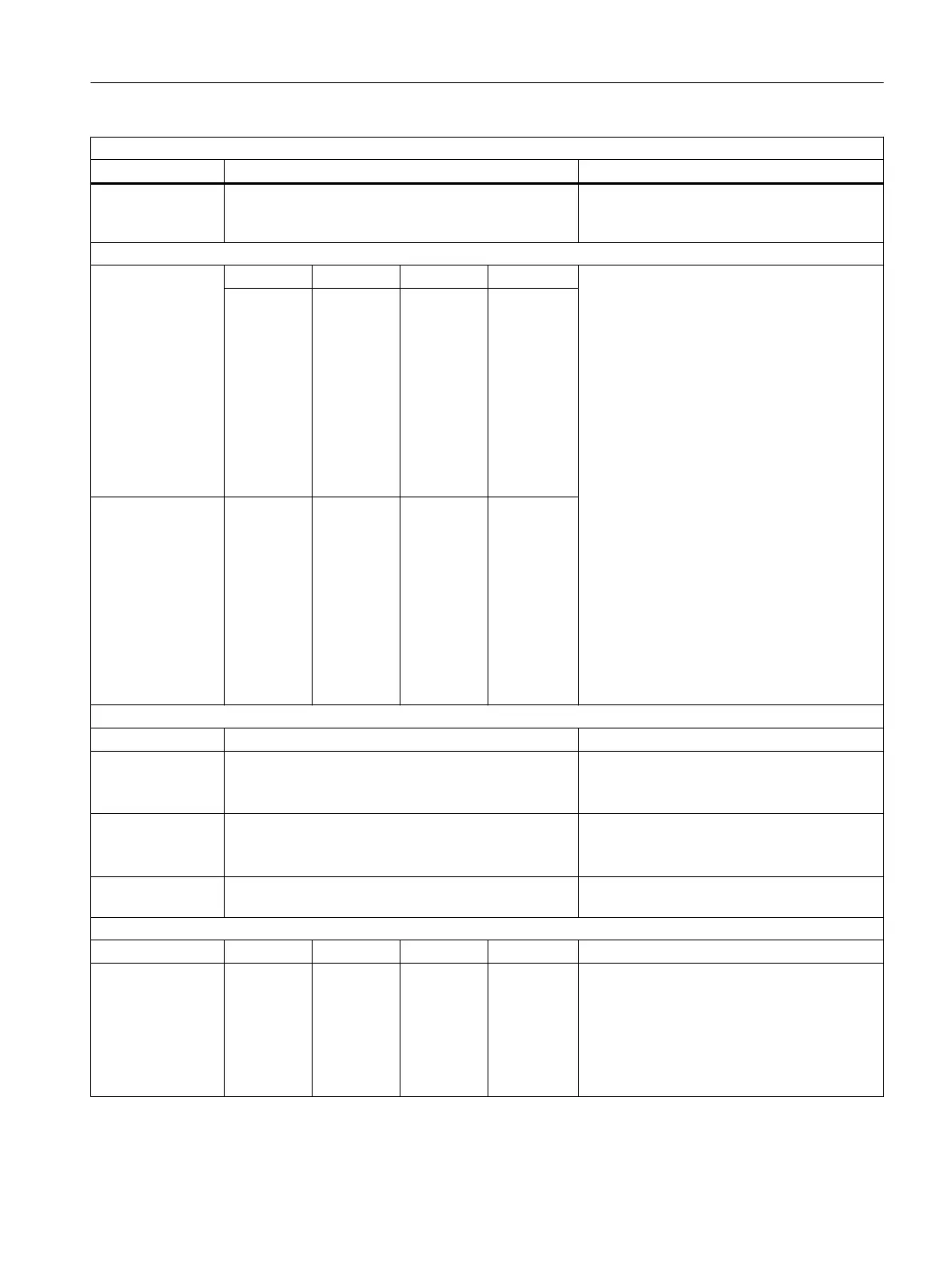

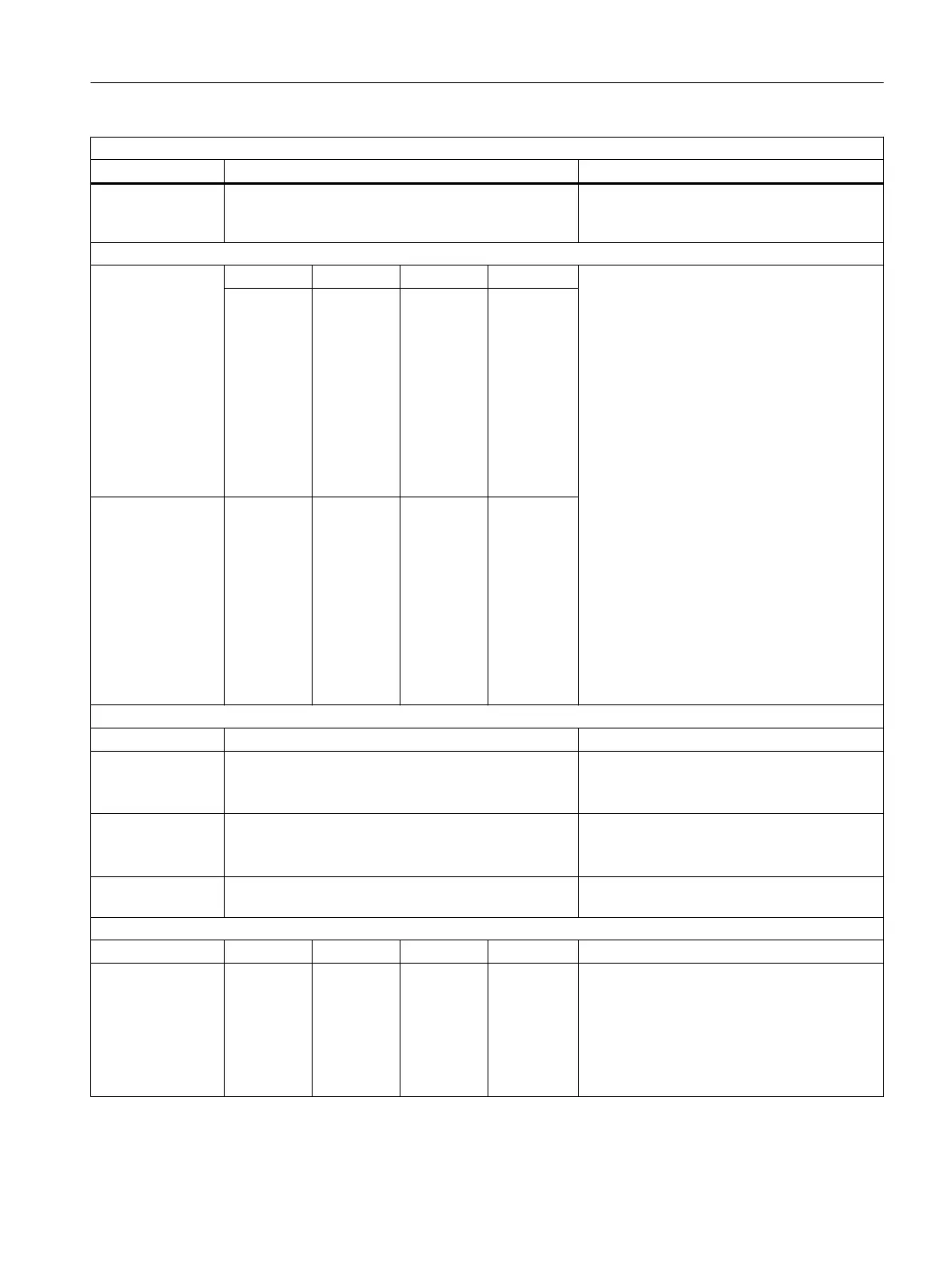

Program coordination

Identifier Parameter Explanation

WAITS INT:

Spindle number

Wait until the specified spindles that were pre‐

viously programmed with SPOSA, reach their

programmed end point

RET 1. 2. 3. 4. End of subprogram with no function output to

the PLC

If the 1st parameter (jump destination) is speci‐

fied, the return jump is first made to the block

after the calling block. The target is then sought

depending on the programming (RET or

RETB) according to the following strategy:

● RET:

Search in the direction of the end of the

program. A search is made toward the start

of the program if the search was not suc‐

cessful.

● RETB:

Search in the direction of the start of the

program. A search is made toward the end

of the program if the search was not suc‐

cessful.

INT (or

STRING):

Jump tar‐

get (block

no./ mark‐

er) for re‐

turn

INT:

0:

Return

jump to

jump desti‐

nation from

1st par.

> 0:

Return to

the follow‐

ing block

INT:

Number of

subpro‐

gram levels

to be skip‐

ped

BOOL:

Return to

first block in

the main

program

RETB INT (or

STRING):

Jump tar‐

get (block

no./ mark‐

er) for re‐

turn

INT:

0:

Return

jump to

jump desti‐

nation from

1st par.

> 0:

Return to

the follow‐

ing block

INT:

Number of

subpro‐

gram levels

to be skip‐

ped

BOOL:

Return to

first block in

the main

program

1. - n.

GET AXIS:

Axis identifier ***

)

Assign machine axis(axes)

The specified axes must be released in the

other channel with RELEASE

GETD AXIS:

Axis identifier ***

)

Assign machine axis(axes) directly

The specified axes must not be released with

RELEASE

RELEASE AXIS:

Axis identifier ***

)

Release machine axis(axes)

1. 2. 3. 4.

PUTFTOC REAL:

Offset value

INT:

Parameter

number

INT:

Channel

number

or

channel

name from

MD20000*

)

INT: Spin‐

dle number

Change of fine tool compensation

Tables

4.4 Predefined procedures

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1277

Loading...

Loading...