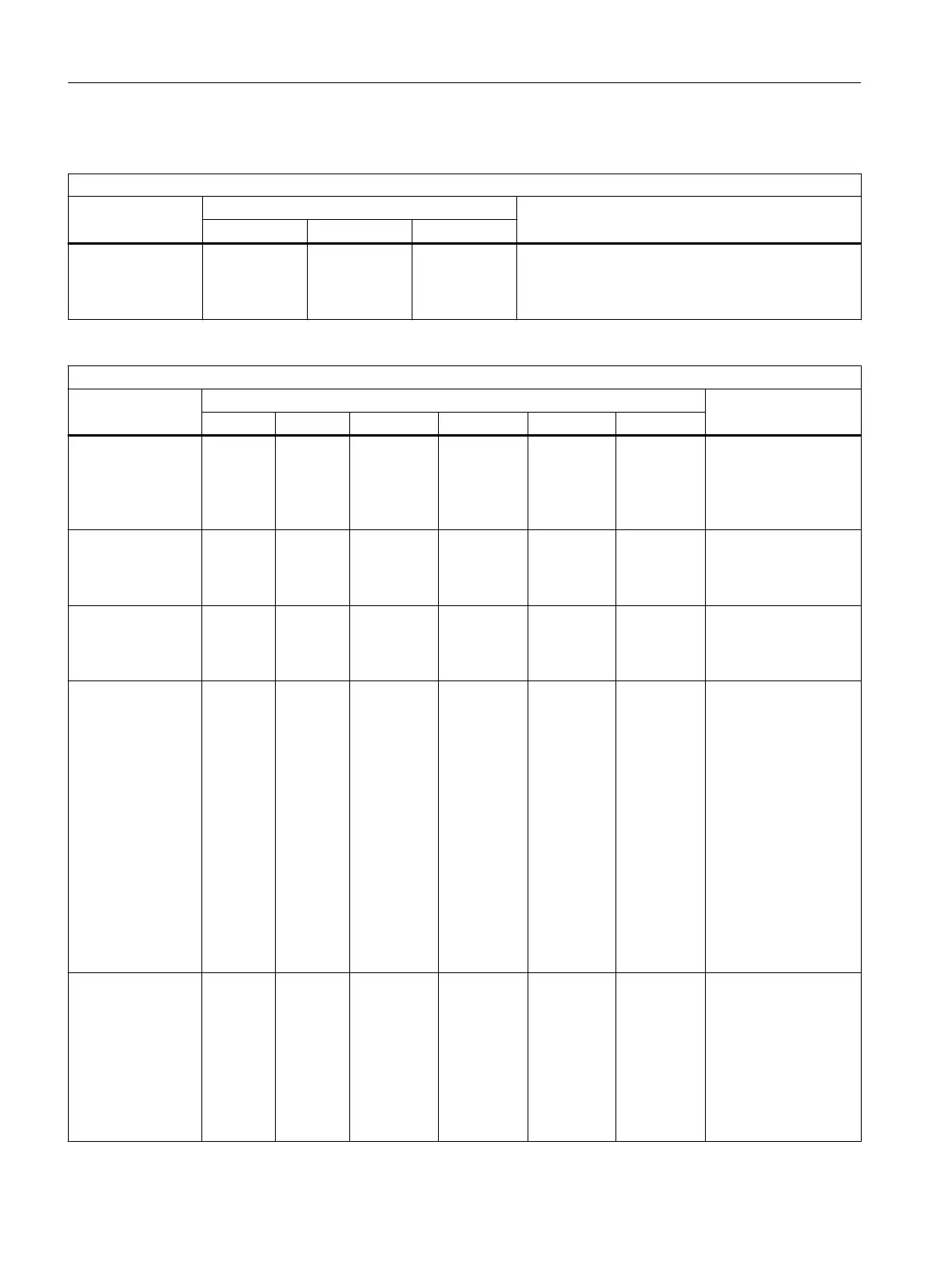

Tool orientation

Identifier Parameter Explanation

1. 2. 3.

ORIRESET REAL:

Initial setting,

1st geometry

axis

REAL:

Initial setting,

2nd geometry

axis

REAL:

Initial setting,

3rd geometry

axis

Initial setting of the tool orientation

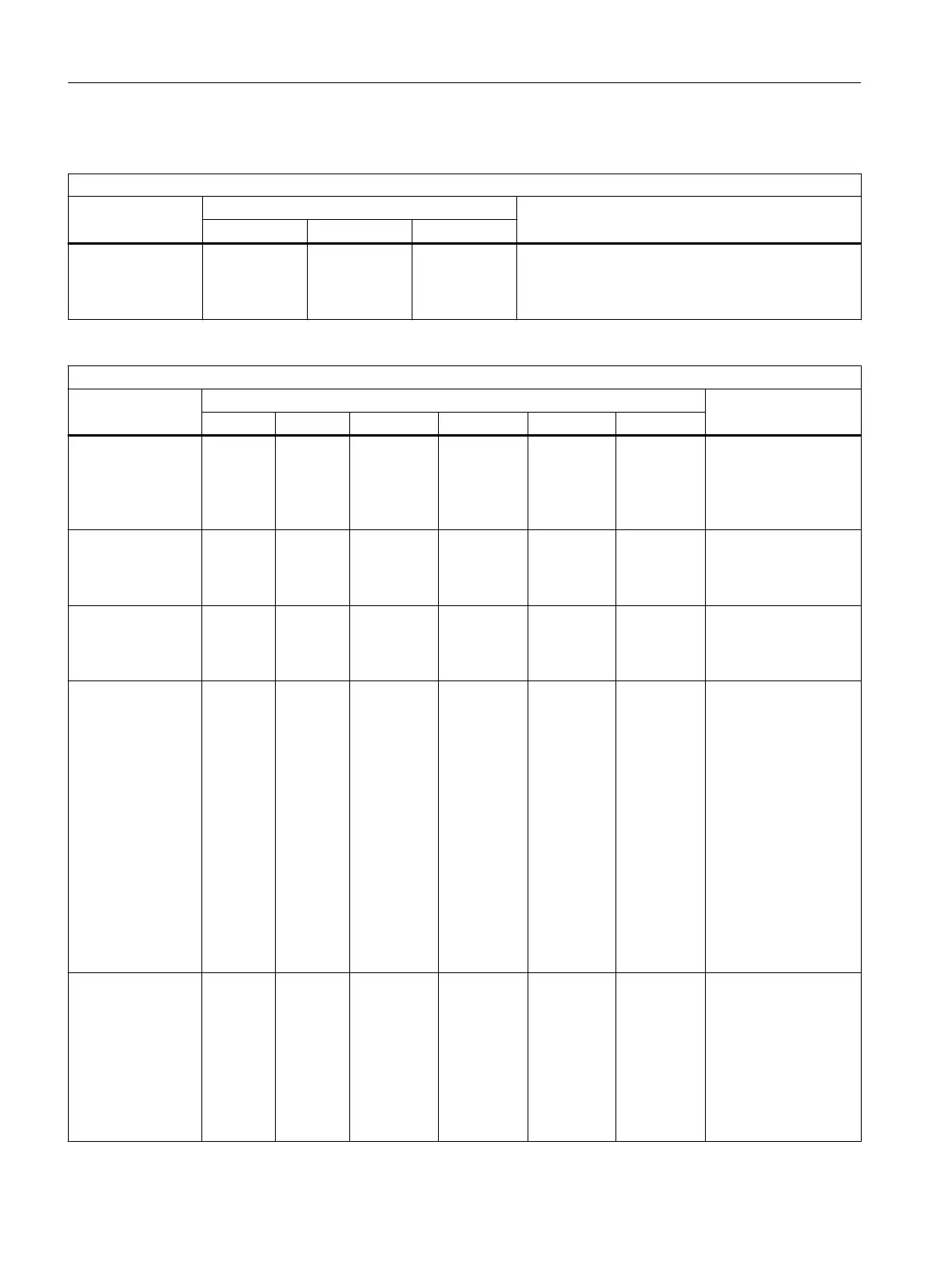

Synchronous spindle

Identifier Parameter Explanation

1. 2. 3. 4. 5. 6.

COUPDEF AXIS:

Follow‐

ing spin‐

dle

AXIS:

Leading

spindle

REAL:

Numerator

of transmis‐

sion ratio

REAL:

Denomina‐

tor of trans‐

mission ra‐

tio

STRING[8]:

Block

change be‐

havior

STRING[2]:

Coupling

type

Define synchronous

spindle grouping

COUPDEL AXIS:

Follow‐

ing spin‐

dle

AXIS:

Leading

spindle

Delete synchronous

spindle grouping

COUPRES AXIS:

Follow‐

ing spin‐

dle

AXIS:

Leading

spindle

Reset coupling param‐

eters to configured MD

and SD values

COUPON AXIS:

Follow‐

ing spin‐

dle

AXIS:

Leading

spindle

REAL:

Switch-on

position of

the follow‐

ing spindle

Switch-on synchro‐

nous spindle coupling

If a switch-on position

is specified for the fol‐

lowing spindle (angu‐

lar offset between FS

and LS that refers --

absolutely or incre‐

mentally -- to the zero

degree position of the

LS in the positive direc‐

tion of rotation), the

coupling is only switch‐

ed on when the speci‐

fied position is

crossed.

COUPONC AXIS:

Follow‐

ing spin‐

dle

AXIS:

Leading

spindle

Switch-on synchro‐

nous spindle coupling

With COUPONC, the

currently active speed

of the following spindle

is taken over when

switching on the cou‐

pling

(M3/M4 S...).

Tables

4.4 Predefined procedures

NC programming

1282 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...