Further information

Tool length offsets

Depending on the type of programming, programmed tool length offsets are assigned either to

the tool length components L1, L2 and L3 (TOFFL) stored in the compensation memory or to

the geometry axes (TOFF). The programmed offsets are treated accordingly for a plane

change (G17/G18/G19 ↔ G17/G18/G19):

● If the offset values are assigned to the tool length components, the directions in which the

programmed offsets apply are replaced accordingly.

● If the offset values are assigned to the geometry axes, a plane change does not affect the

assignment in relation to the coordinate axes.

The following setting data is evaluated when assigning the programmed offset values to the tool

length components:

SD42940 $SC_TOOL_LENGTH_CONST (change of tool length components on change of

planes).

SD42950 $SC_TOOL_LENGTH_TYPE (assignment of the tool length offset independent of

tool type).

If this setting data has valid values not equal to 0, then these have priority over the contents of

G group 6 (plane selection G17/G18/G19) or the tool type ($TC_DP1[<T no.>, <D no.>])

contained in the tool data. This means that this setting data affects the evaluation of the offsets

in the same way as the tool length components L1 to L3.

Tool radius offset

The TOFFR address has almost the same effect as the OFFN (Page 251) address. There is

only a difference with active peripheral curve transformation (TRACYL) and active slot side

compensation. In this case, the tool radius is affected by OFFN with a negative sign, but by

TOFFR with a positive sign.

OFFN and TOFFR can be effective simultaneously. They then generally have an additive effect

(except for slot side compensation).

Tool change

All offset values are retained during a tool change (cutting edge change). This means that they

are also effective for the new tool (new cutting edge).

System variables for reading the current offset values

The currently effective offsets can be read with the following system variables:

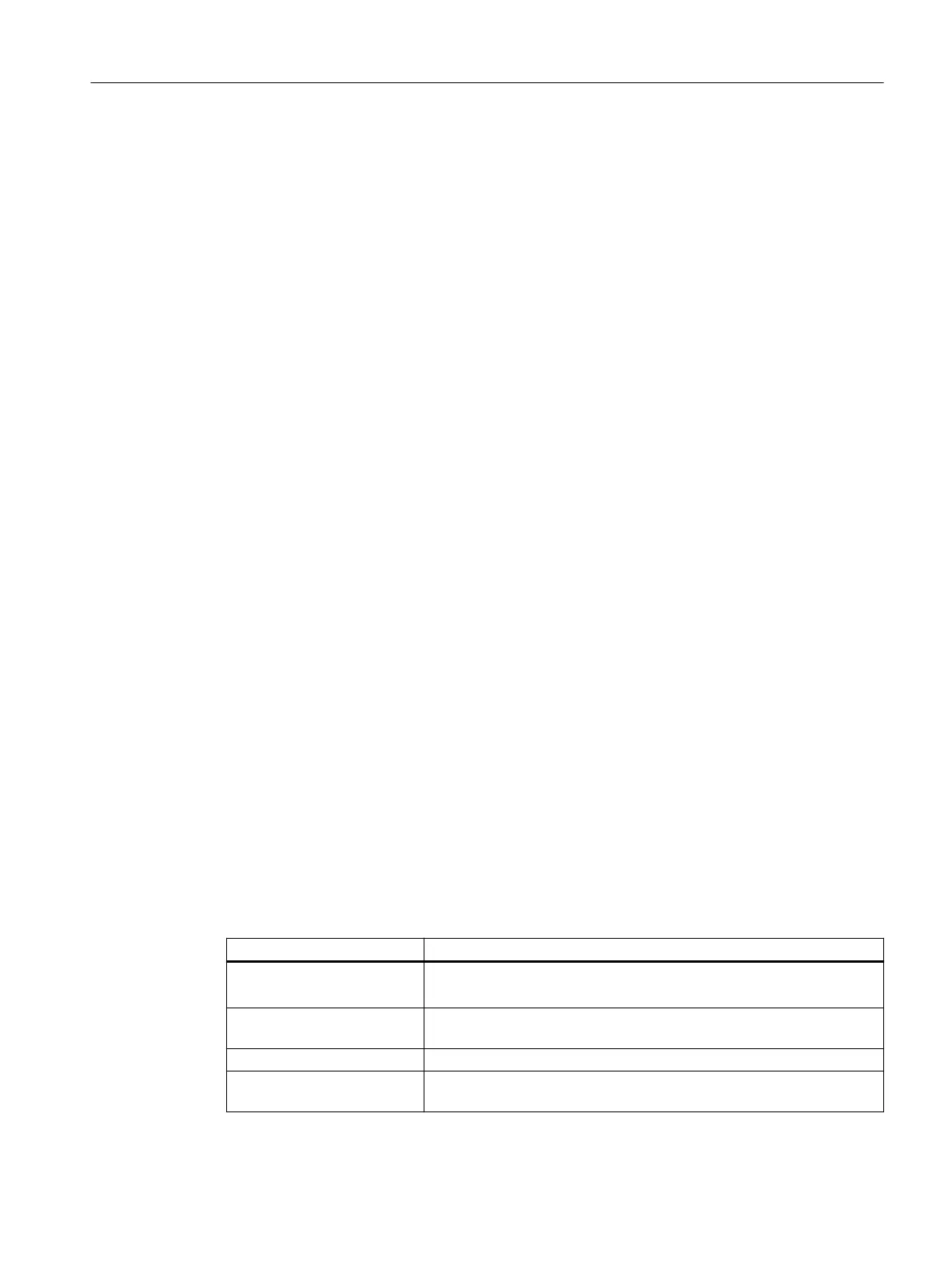

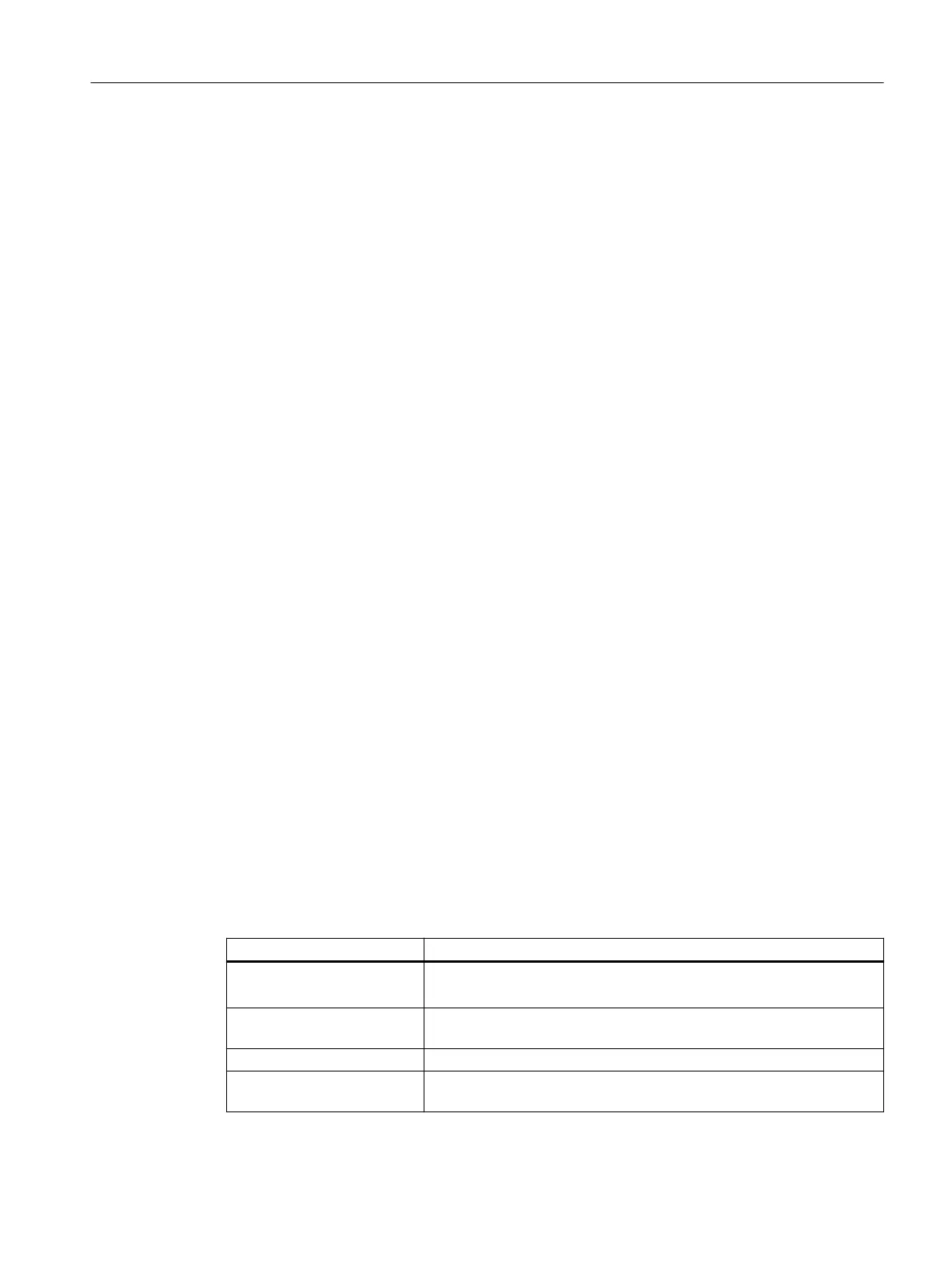

System variable Meaning

$P_TOFFL [<n>]

with 0 ≤ n ≤ 3

Reads the current offset value of TOFFL (for n = 0) or TOFFL[1...3] (for

n = 1, 2, 3) in the preprocessing context.

$P_TOFF [<GeoAx>] Reads the current offset value of TOFF[<GeoAx>] in the preprocessing

context.

$P_TOFFR Reads the current offset value of TOFFR in the preprocessing context.

$P_TOFFCR Reads the current offset value of the corner radius in the preprocessing

context.

Fundamentals

2.5 Tool offsets

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 87

Loading...

Loading...