Issue 01/05 Information for the CANopen master

CANopen Option Module Operating Instructions

6SE6400-5BC00-0BP0

107

6.3 Parameter settings for the modes

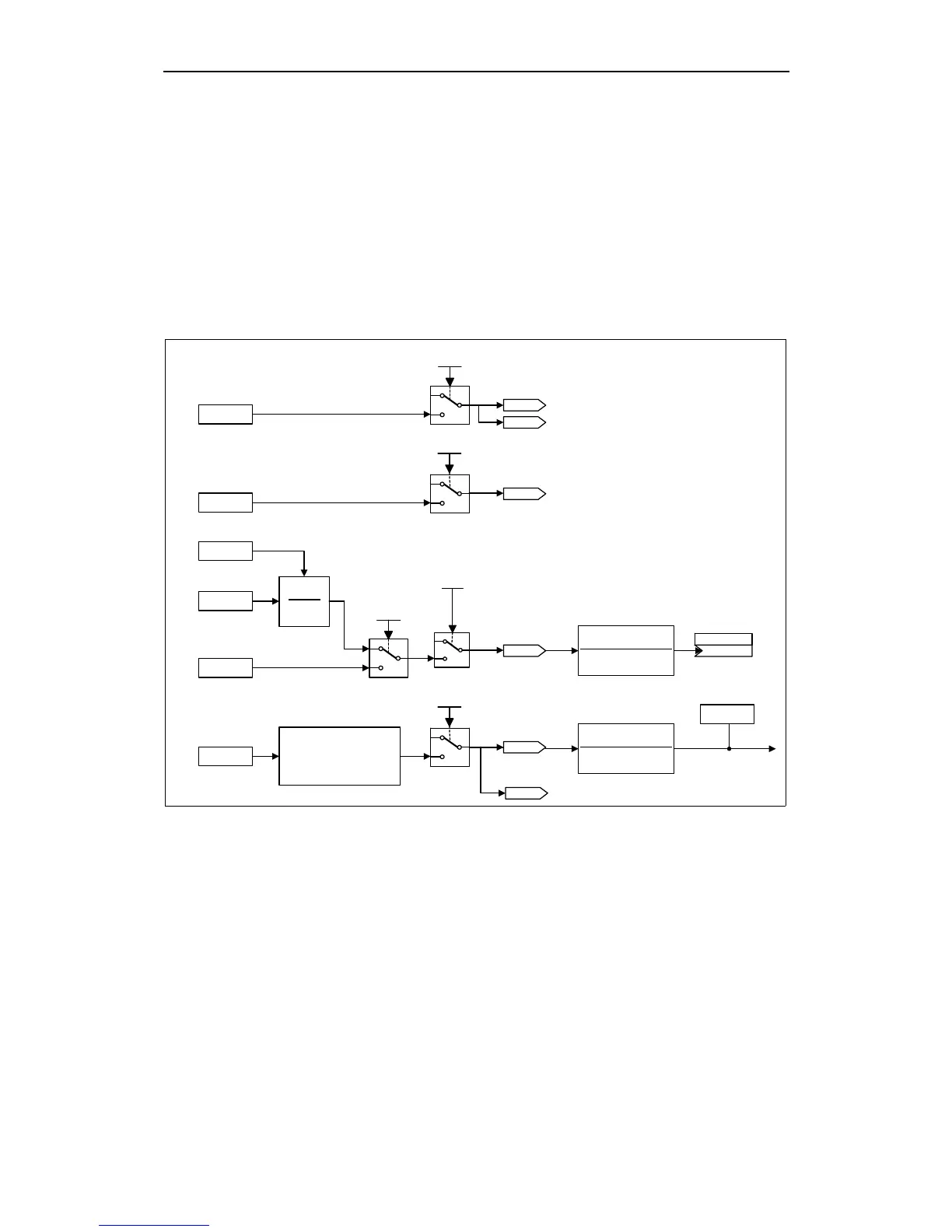

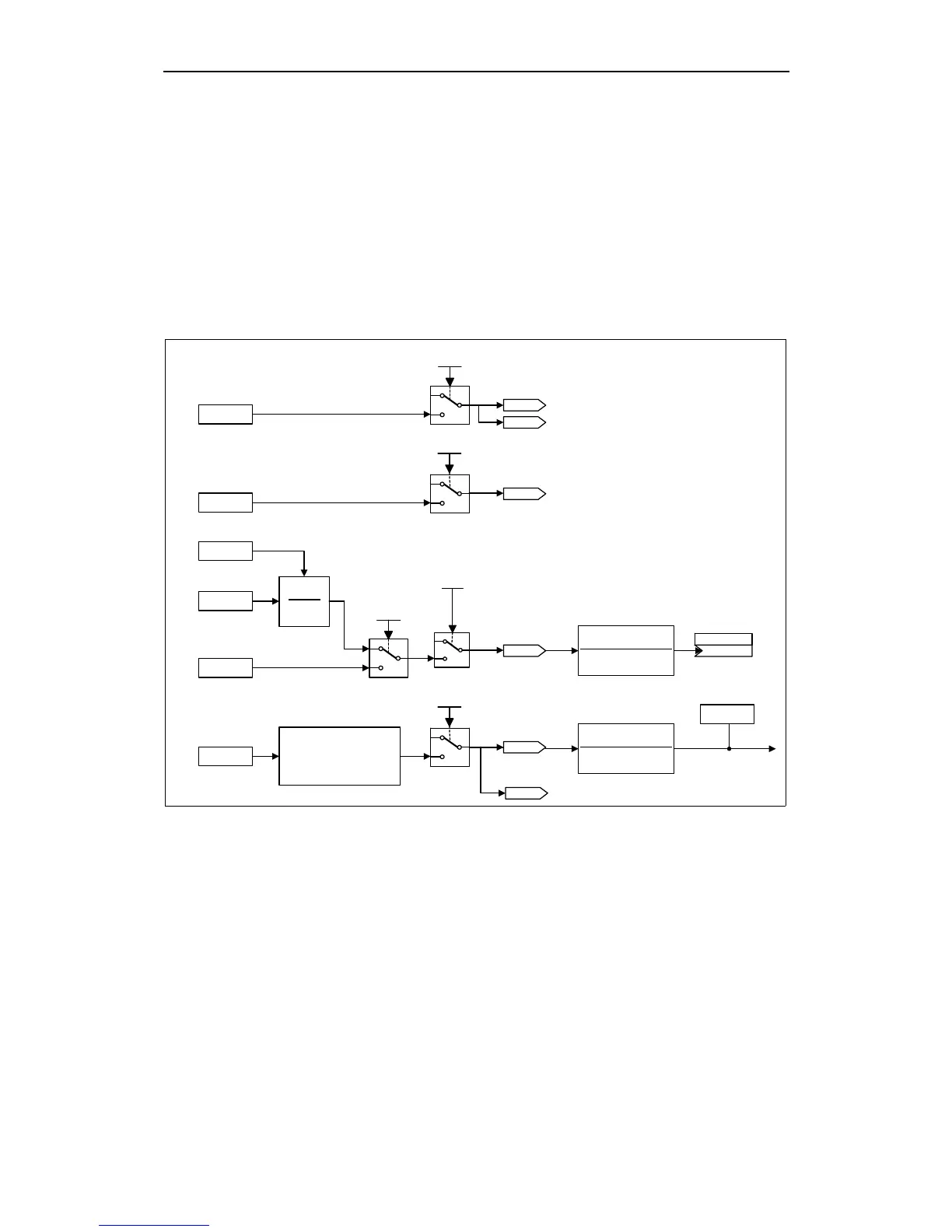

Fig. 6-1 to Fig. 6-4 give an overview to the process data connections and show

appropriate BICO connections for velocity mode and torque profile mode.

6.3.1 Velocity Mode

2802.4H

free object to

MICROMASTER

0

1

RPDO5 P2041.2 bit 03

RPDO6 P2041.3 bit 03

P2050.3

Free connection

2802.3H

free object to

MICROMASTER

0

1

RPDO5 P2041.2 bit 02

RPDO6 P2041.3 bit 02

P2050.2

Free connection

4000H

604EH

604EH

V1_velocity_reference

6052H

V1_nominal_percentage

6042H

V1_target_velocity

P1070 (755.0)

KK

Main Setpoint

0

1

RPDO5 P2041.2 bit 07

RPDO6 P2041.3 bit 07

0

1

RPDO5 P2041.2 bit 01

RPDO6 P2041.3 bit 01

P2050.1

Drive

Frequency Setpoint

BICO connection:

P0700 = 6

Conversion from

CANopen control word

to MICROMASTER

control word

6040H

CANopen

control word

P2050.0

Drive

Control Word

0

1

RPDO5 P2041.2 bit 00

RPDO6 P2041.3 bit 00

r0054

Drive Control Word

r2090

Drive

Control Word

BICO connection:

P0700 = 6

r2091

Fig. 6-1 Process Data transfer from CAN object dictionary to MICROMASTER 420/430/440 using

RPDO5 or RPDO6

Loading...

Loading...