(GLWLRQ$ &RPPXQLFDWLRQZLWK0,&520$67(5YLD352),%86'3

PROFIBUS Optional Board Operating instructions

6SE6400-5AK00-0BP0

25

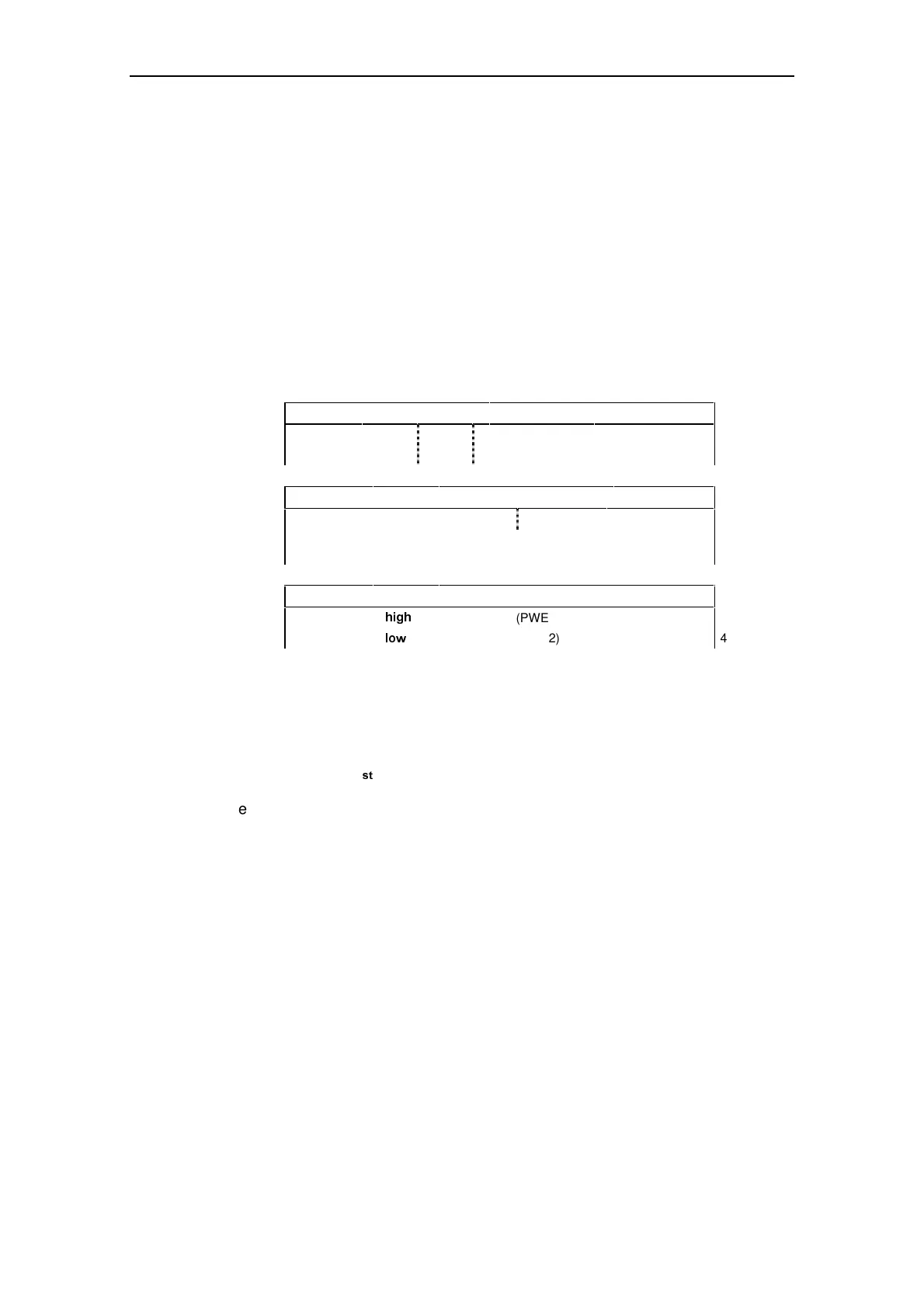

3.:PHFKDQLVPIRUSURFHVVLQJSDUDPHWHUV

3DUDPHWHUDUHD3.:

Using the PKW mechanism you can process and monitor parameters (write/read)

as described below:

3UHFRQGLWLRQ

PPO type 1 on MICROMASTER4 in accordance with PROFIDrive Profile version

2.0

or

use of acyclical channel in conjunction with data block 100

The parameter area includes at least 4 words.

Parameter identifier (PKE) 1

st

word

Bit no.:15 121110 0

AK 0 PNU

Parameter index (IND) 2

nd

word

Bit no.: 15 8 7 0

Structure and meaning are dependent on mode of data exchange used (see

following pages)

Parameter value (PWE)

Parameter value

KLJK

(PWE1) 3

rd

word

Parameter value

ORZ

(PWE2) 4

th

word

AK:

PNU:

Request or response identifier

Parameter number

Fig. 3-4 Structure of parameter area (PKW)

3DUDPHWHULGHQWLILHU3.(

VW

ZRUG

The parameter identifier (PKE) is always a 16-bit value.

Bits 0 to 10 (PNU) contain the number of the relevant parameter.

Bit 11 is reserved.

Bits 12 to 15 (AK) contain the request or the response identifier.

The meaning of the request identifier for request telegrams (master → converter) is

shown in Table 3-3. Request identifiers 11 to 14 are specific to MICROMASTER

and not defined in the PROFIDrive Profile.

The meaning of the response identifier for response telegrams (converter →

master) is shown in

Table 3-4. The request identifier will determine which response identifiers are

possible. If the response identifier is 7 (cannot process request), then one of the

fault numbers listed in Table 3-5 will be stored in parameter value 2 (PWE2).

Loading...

Loading...