Do you have a question about the Siemens SIMATIC CPU 410 and is the answer not in the manual?

Manual overview, changes from previous versions, and relevant components.

Industrial security concepts, product security functions, and recommendations for secure operation.

Overview of user documentation, listing manuals for setup, module data, and system components.

Purpose of redundant automation systems, fail-tolerant vs. fail-safe, and reasons for fault-tolerance.

Configuration information, S7-400 hardware components, and examples of S7-400H configurations.

Definition of stand-alone operation, hardware components, central controller, expansion units, and power supply.

Operation requirements, hardware, CPUs, racks, power supply, synchronization modules, and fiber-optic cables.

Rules for fault-tolerant station assembly, CPU insertion, module requirements, and system expansion cards.

Usage of SIMATIC S7 I/O modules, function modules, and communication modules with CPU 410.

Configuration variants for I/O modules: one-sided, single-channel switched, and dual-channel.

Configuring CPU 410-5H using STEP 7 HW Config and optional software.

License management, system expansion card usage, project expansion, and PO expansion by replacing SEC.

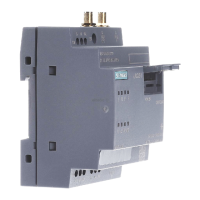

Arrangement of controls, LED displays for top/bottom bars, interfaces, and reset button.

Monitoring functions and error messages, overview of errors, causes, and responses with error LEDs.

RUN/STOP LEDs, MSTR/RACK/INTF/EXTF/BUS/IFM/LINK/RX/TX/REDF LEDs, and their states.

Connectable devices, connectors, and redundant operation for PROFIBUS DP interface.

IP address assignment, connectable devices, connectors, and properties of PROFINET IO interfaces.

Default parameter values, parameter blocks, assignment tool, and further settings for CPU 410.

Startup of DP master system, PROFIBUS address, and output/input data length.

Diagnostics using LEDs, meaning of BUS1F LED, and diagnostic addresses for DP master.

What is PROFINET IO, RT communication, and relevant documentation available online.

Functions of PROFINET IO, graphic overview of connection paths, and examples of connection paths.

Simple IO device replacement, requirements, and additional information.

Definition, reasons, observations, fault tolerance LEDs, configuration procedure, and expansion to fault-tolerant system.

Ensuring functional safety, SIMATIC Safety Integrated, fail-safe CPU functions, S7 F/FH Systems, and fail-safe I/O modules.

Objectives of redundant systems, why fault-tolerant, and redundant I/O.

I/O installation types for fault-tolerant systems (PROFINET IO, PROFIBUS DP).

Definition, addressing, configuration at PROFIBUS DP interface, and notes on reconfiguration in RUN mode.

System redundancy configurations for PROFINET IO, logical topology, and S2/R1 devices.

CPU reaction in RUN mode (program execution, I/O access), single mode, link-up, update, and redundant system mode.

S7-400H structure, active redundancy meaning, master/standby convention, and master-standby assignment.

Processing the self-test, response to errors during self-test, and causes of hardware faults.

Memory reset process, LED behavior during reset, and data retained after reset.

Effects of link-up/update on user program execution, communication functions, and REDF LED indication.

Possible PG commands for link-up/update based on firmware, hardware, and connection conditions.

Program execution interruption during updating, monitoring times, and factors influencing cycle time.

Time response during link-up/update, influencing factors, and determining monitoring times.

Calculation of monitoring times using STEP 7 or formulas, and monitoring time accuracy.

User program share of maximum inhibit time for priority classes > 15 and its calculation.

Factors influencing time response: data blocks, SFBs, system modifications, and DP/PROFINET expansion.

Input signal requirements during update, communication links, and memory reset on link-up cancelation.

Automation system protection: signed firmware, protection levels, SysLogEvents, Field Interface Security, and Block Privacy.

Defining protection levels, setting levels in HW Config, and additional aspects of CPU protection.

CPU 410 security event support, parameter description for saved files, and event overview.

Activating interface protection, features of disable, and configuring security events.

Using S7-Block Privacy to protect functions and blocks from unauthorized access.

Retentivity of user program, memory requirements, extended runtimes, and S7 block privacy information.

Overview of type update, caution when replacing CPU, and buffering with battery.

CPU factory settings, reset procedure, and LED patterns during CPU reset.

CPU operating state, reset procedure during operation, and reset in stand-alone operation with restart.

Response to fault detection, automatic reboot for one-sided defects in fault-tolerant systems.

Procedure for reading and saving service data for customer support, and note on security events.

Firmware update procedure in stand-alone mode: basic steps, requirements, and two-stage vs. one-stage updates.

Firmware update requirements and procedures for redundant mode, including two-stage and one-stage updates.

Process of S7 stations receiving local time from a central source and time-of-day synchronization requirements.

Time-of-day synchronization options via PROFINET IO, backplane bus, and PROFIBUS DP interfaces.

Time-of-day synchronization using NTP or SIMATIC methods via PROFINET IO.

CPU 410 as time slave on S7-400 backplane bus, synchronization via CP with LAN clock.

Configuring CPU 410 as time master, specifying synchronization interval, and setting time as slave.

Assignment of an event to its acquisition time, IO controller sending time to IO subsystem, and high-precision time stamping.

Examining chronological relationships between time-stamped events from different S7 stations.

Time stamping precision as the maximum difference of time stamps from simultaneous signal recordings.

Resolution of time stamping as the smallest possible time difference between two time stamps.

Systems requiring shutdown-free operation, using CiR for configuration changes in RUN, and hardware requirements.

Permitted changes: adding/removing IO devices, modules, parameters, ports, update time, and process image partition.

Basic operating steps in RUN mode: adding/removing IO devices/modules, rebuilding hardware, changing process image partition.

Requirements for reconfiguration: using channels, not changing addresses, CiR capability of devices.

Motivation for CiR via PROFINET DP, hardware requirements for PROFIBUS DP, and software requirements.

Permitted changes for PROFIBUS DP: adding modules, reassigning parameters, replacing modules, adding slaves, changing process image partition.

Available CiR elements: DP master system, PA master system, and modular DP slave.

Basic steps in STOP state: defining, deleting, editing CiR elements, downloading configuration.

Requirements for reconfiguration: using channels, not changing addresses, CiR capability.

Rules for system modification during runtime for ET 200SP HA modules.

Effects on OS functions during CiR sync: process image update and user program processing.

H-CiR wizard for plant changes in redundant operation, minimizing risks and avoiding bumps.

Modifying central components: CPU parameters, module reconfiguration, and upgrading CPU version.

Procedure for adding interface modules, de-energized requirements, and wizard steps.

Enabling high plant availability via H-CiR in process mode/RUN during redundant operation.

Permitted changes for PROFINET IO in redundant operation: adding/removing IO systems, controllers, devices, modules, parameters.

Making plant changes with CPU 410 in redundant mode without interruption, and requirements for switched I/O.

Modifying hardware live, downloading configurations, synchronization link, and replacing distributed I/O components.

Procedure for modifying hardware components, initial situation, and exceptions.

Procedure for offline hardware modifications related to component removal.

Editing CPU parameters in operation, editable parameters, and notes on protected parameters.

Determining reconfigurable modules, PDEV submodule reconfiguration, and notes on protected parameters.

CPU replacement situation, system reaction to failure, and requirements for CPU replacement.

IO device replacement situation, system reaction, and procedure for changing an IO device.

DP master failure situation, system reaction, and replacement procedure.

Function of synchronization modules, distance between CPUs, types, and usage notes.

Fiber-optic cable installation, bending radii, quality assurance, storage, and open installation.

Cable pull-in, pressure, heat influence, and selection criteria for fiber-optic cables.

Use of SEC, scaling/licensing, and variants for CPU 410-5H and CPU 410E.

General info, product function, engineering, CiR, input current, power loss, memory, backup, CPU processing, blocks, clock sync, interfaces, protocols.

General info, product function, engineering, CiR, input current, power loss, memory, backup, CPU processing, blocks, clock sync, interfaces, functionality, PROFINET IO controller services, address area, hardware config.

PCS7 System Expansion Cards PO 0, 100, 500, 1600, 200M: general info, memory, address area, digital/analog channels, standards, hazardous areas, ambient conditions, dimensions, weights.

PO configuration limits, DP master interface, PN/IO controller, and fail-safe operation for CPU 410 SMART.

General info, product function, engineering, CiR, input current, power loss, memory, backup, CPU processing, blocks, counters/timers, clock sync, interfaces, functionality, PROFINET IO controller services, address area, hardware config, multicomputing, interface modules, DP masters, IO controllers, media redundancy.

Monitor/Modify via PROFIBUS, bus topology determination, and adding modules to ET 200M/ET200iSP.

Reading diagnostics data with STEP 7, event detection, and evaluating diagnostics data in user program.

System status list description, compatibility, and comparison of lists for PROFINET IO and PROFIBUS DP.

Rules for fault-tolerant station arrangement: CPU insertion, DP master interfaces, module identity, layout rules.

User program rules for S7-400H, synchronization, and specific blocks for redundancy functions.

Display in SIMATIC Manager, communication functions, and their behavior in redundant/single modes.

Table of communication services: PG, OP, S7, routing, PROFIBUS DP, PROFINET IO, SNMP, Open IE.

Fundamentals and concepts of fault-tolerant communications, including redundant systems and fault-tolerant communication.

Choice of physical transmission medium based on expansion, fault tolerance, and transfer rate.

Availability for communication between fault-tolerant and standard systems using redundant plant bus.

Increasing availability using redundant plant bus (duplex fiber-optic ring, dual electrical bus).

Processing communication jobs in time slices, data formats, and coordination of shared data access.

Objective of link-up: master/standby changeover or achieving redundant system state.

User program rules for S7-400H, synchronization, and specific blocks for redundancy functions.

Redundant I/O at user level, configurations (one-sided, switched), and notes on monitoring times.

Decisive factors in cycle time, calculation, time slice model, and process image.

Quantitative assessment of redundant systems based on reliability and availability parameters.

Comparison of systems with centralized I/Os, framework conditions for calculation, and configurations with redundant CPU 410.

List of function modules (FM) and communication processors (CP) usable centrally with CPU 410-5H.

List of function modules (FM) and communication processors (CP) usable for distributed switched use.

MTA terminal modules for connecting field devices to I/O modules of ET 200M stations.

Interconnection of digital output modules with and without external diodes.

Connection of encoder to SM 331; AI 8 x 0/4...20mA HART via MTA.

Connection of encoder to SM 322; AI 8 x 0/4...20mA HART via MTA.

Connection of two redundant encoders to SM 321; DI 16 x DC 24 V.

Connection of two redundant encoder pairs to SM 321; DI 32 x DC 24 V.

Connection of two redundant encoders to SM 321; DI 16 x AC 120/230 V.

Connection of two redundant encoders to SM 321; DI 8 x AC 120/230 V.

Connection of two redundant encoder pairs to SM 321; DI 16 x DC 24V.

Connection of two redundant encoder pairs to SM 321; DI 16 x DC 24V.

Connection of an actuator to two SM 326; DO 10 x DC 24V/2A.

Connection of two redundant encoders to SM 326; DI 8 x NAMUR.

Connection of one encoder to two SM 326; DI 24 x DC 24 V.

Connection of a redundant encoder to SM 421; DI 32 x UC 120 V.

Connection of two redundant encoder pairs to SM 421; DI 16 x DC 24 V.

Connection of two redundant encoders to SM 421; DI 32 x DC 24 V.

Connection of two redundant encoders to SM 421; DI 32 x DC 24 V.

Connection of an actuator to two SM 322; DO 8 x DC 24 V/2 A.

Connection of an actuator to two SM 322; DO 32 x DC 24 V/0.5 A.

Connection of an actuator to two SM 322; DO 8 x AC 230 V/2 A.

Connection of an actuator to two SM 322; DO 16 x DC 24 V/10 mA [EEx ib].

Connection of an actuator to two SM 322; DO 16 x DC 15 V/20 mA [EEx ib].

Connection of an actuator to two SM 322; DO 8 x DC 24 V/0.5 A.

Connection of an actuator to two SM 322; DO 16 x DC 24 V/0.5 A.

Connection of two actuators to SM 332; AO 8 x 12 Bit.

Connection of an actuator to SM 332; AO 4 x 0/4...20 mA [EEx ib].

Connection of an actuator to SM 422; DO 16 x AC 120/230 V/2 A.

Connection of an actuator to SM 422; DO 32 x DC 24 V/0.5 A.

Connection of a 2-wire transmitter to SM 331; AI 4 x 15 Bit [EEx ib].

Connection of a transmitter to SM 331; AI 8 x 12 Bit.

Connection of a transmitter to SM 331; AI 8 x 16 Bit.

Connection of a transmitter to SM 331; AI 8 x 16 Bit.

Connection of a thermocouple to SM 331 AI 6xTC 16Bit iso.

Connection of a 4-wire transmitter to SM 331; AI 8 x 0/4...20mA HART.

Connection of a 2-wire transmitter to SM 331; AI 8 x 0/4...20mA HART.

Connection of an actuator to SM 332; AO 4 x 12 Bit.

Connection of an actuator to SM 332; AO 8 x 0/4...20mA HART.

| Type | CPU |

|---|---|

| Communication Interfaces | PROFIBUS DP, PROFINET |

| Power Supply | 24 V DC |

| Number of DP masters | 1 |

| Number of PROFIBUS DP slaves | Up to 125 |

| Number of S7 connections | 32 |

| Operating Temperature | 0 to 60 °C |

| I/O Ports | Configurable |

| Product type designation | CPU 410 |

| Digital Inputs | Configurable |

| Digital Outputs | Configurable |

| Analog Inputs | Depends on the I/O modules used with the CPU |

| Analog Outputs | Depends on the I/O modules used with the CPU |

| Number of function blocks (FB) | 256 |

| Number of functions (FC) | 256 |

| Number of data blocks (DB) | 256 |

Loading...

Loading...