Control functions

7.3 Pulse train input position control (PTI)

SINAMICS V90, SIMOTICS S-1FL6

226 Operating Instructions, 04/2019, A5E36037884-007

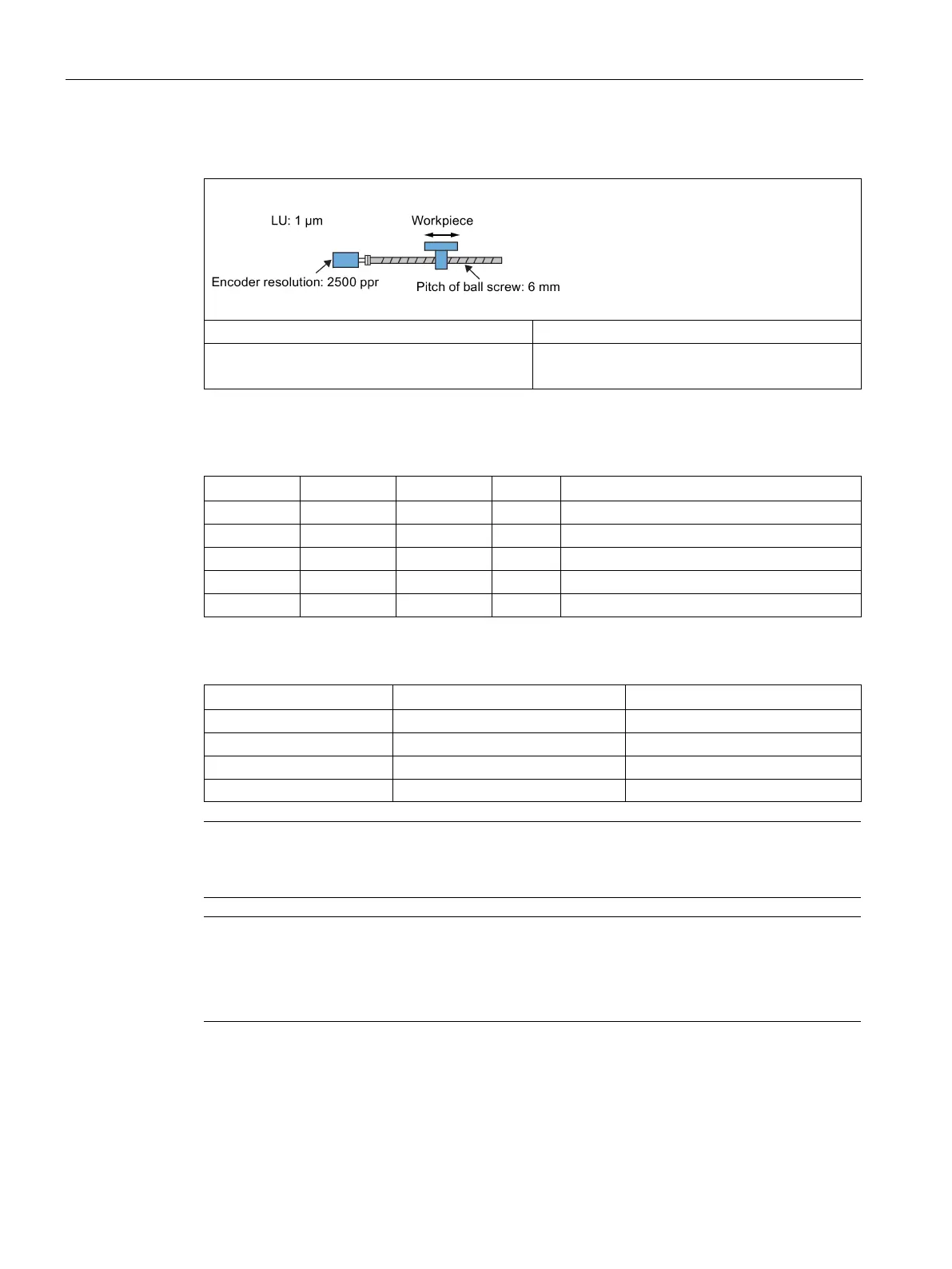

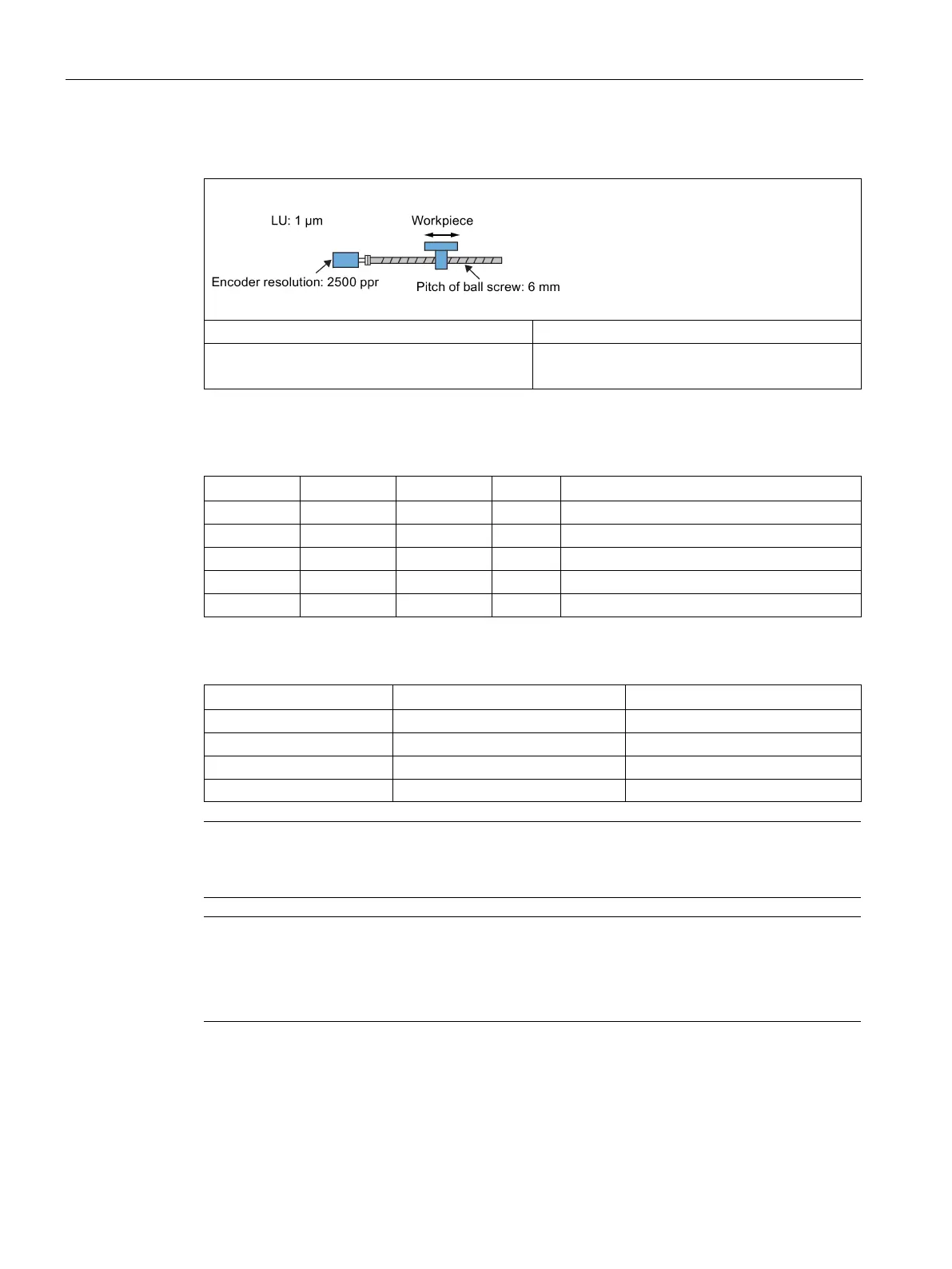

Benefits of electronic gear (example)

Move the workpiece for 10 mm

Required number of setpoint pulses:

2500 ppr × 4 × (10 mm/6 mm) = 16666

Required number of setpoint pulses:

(10 mm × 1000)/1 LU = 10000

The electronic gear ratio is a multiplier factor to pulse train setpoint. It is realized with a

numerator and a denominator. Four numerators (p29012[0], p29012[1], p29012[2].

p29012[3]) and one denominator (p29013) are used for the four electronic gear ratios.

The first numerator of electronic gear

The second numerator of electronic gear

The third numerator of electronic gear

The forth numerator of electronic gear

The denominator of electronic gear

These four electronic gear ratios can be selected with the combination of the digital input

signals EGEAR1 and EGEAR2 (refer to Section "DIs (Page 123)").

Note

After a gear ratio is switched to another one via digital inputs, you need to wait 10 seconds

and then perform SERVO ON

.

Note

The range of electronic gear ratio is from 0.02 to 200.

The electronic gear ratio can be set only at SERVO OFF

state. After the setting, you need to

reference the drive again.

Loading...

Loading...