5

03.04 "Parameters" Operating Area

5.1 Tool data

5

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operator's Guide HMI Advanced (BAD) – 03.04 Edition 5-171

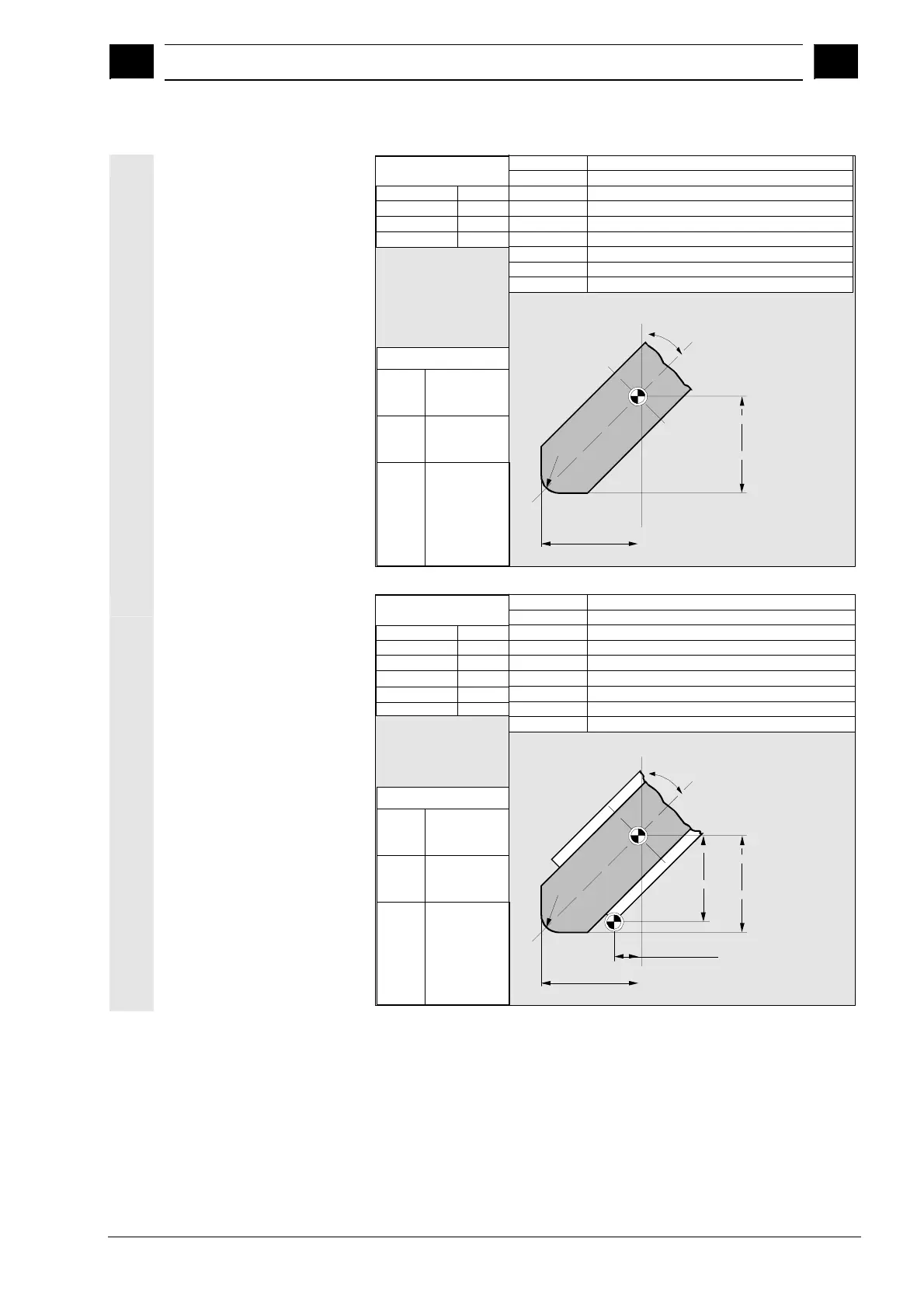

Required offset values

for inclined grinding

wheel with implicit

monitoring selection

F'

Entries in

tool parameters

STC_DP1

STC_DP3

STC_DP4

STC_DP6

403

Length 1

Length 2

Radius

STC_TPG1

STC_TPG2

STC_TPG4

STC_TPG5

STC_TPG6

STC_TPG7

STC_TPG8

STC_TPG3

STC_TPG9

Spindle number

Chaining rule

Minimum wheel radius

Minimum wheel width

Current wheel width

Maximum speed

Max. surface speed

Angle of the inclined wheel

Parameter no. for radius calculation

Wear values according

to requirement

Other values must

be set to zero

Effect

G17:

G18:

G19:

Length 1 in Y

Length 2 in X

Radius in X/Y

Length 1 in X

Length 2 in Z

Radius in Z/X

Length 1 in Z

Length 2 in Y

Radius in Y/Z

F: Toolholder reference point

Radius

Length 2 (Z)

∝

Length

1 (X)

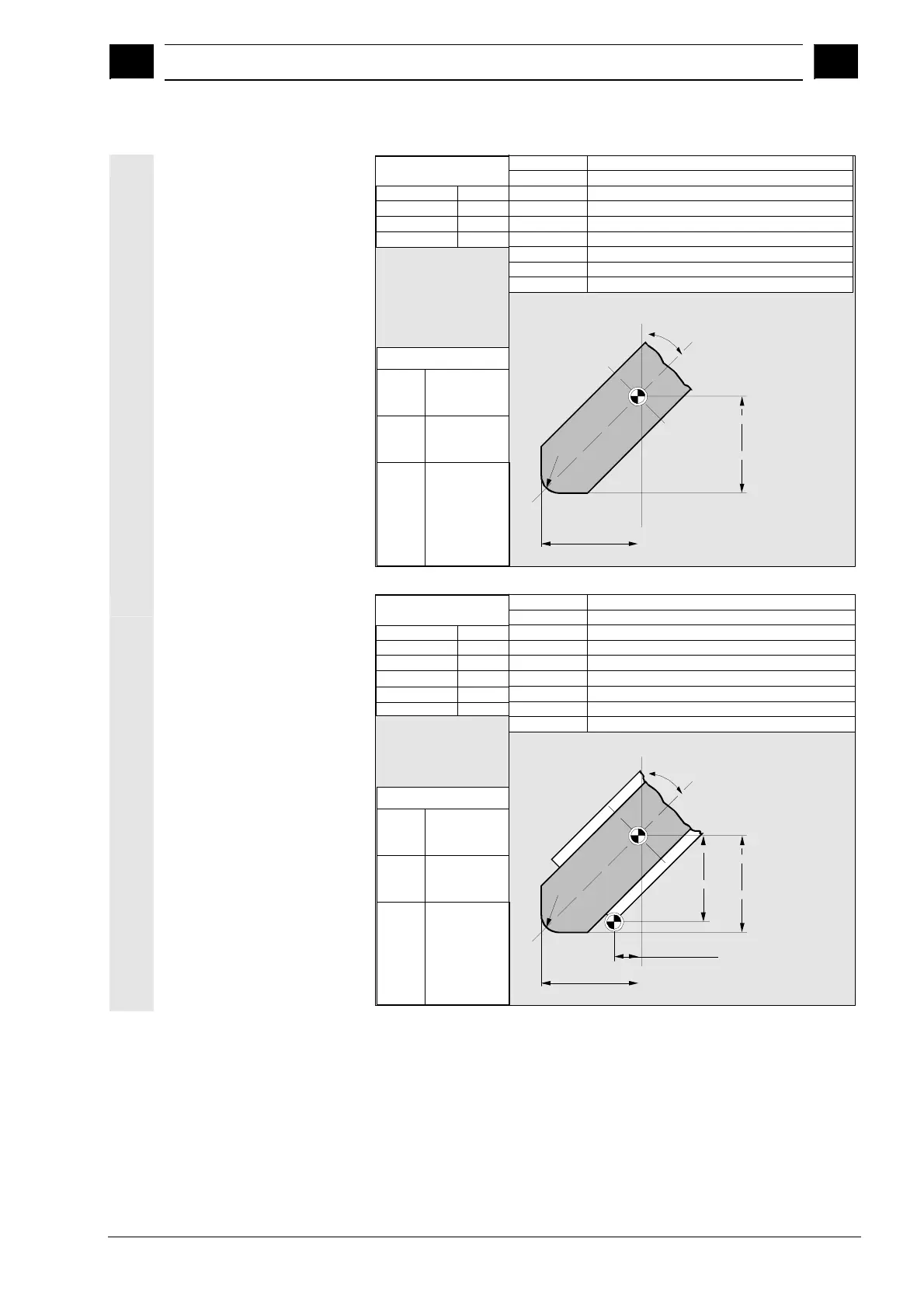

Required offset values

using the example of

inclined grinding wheel

with implicit monitoring

selection

F'

F

Entries in

tool parameters

STC_DP1

STC_DP3

STC_DP4

STC_DP6

403

Length 1

Length 2

Radius

STC_TPG1

STC_TPG2

STC_TPG4

STC_TPG5

STC_TPG6

STC_TPG7

STC_TPG8

STC_TPG3

STC_TPG9

Spindle number

Chaining rule

Minimum wheel radius

Minimum wheel width

Current wheel width

Maximum speed

Max. surface speed

Angle of the inclined wheel

Parameter no. for radius calculation

Wear values according

to requirement

Other values must

be set to zero

Effect

G17:

G18:

G19:

Length 1 in Y

Length 2 in X

Radius in X/Y

Length 1 in X

Length 2 in Z

Radius in Z/X

Length 1 in Z

Length 2 in Y

Radius in Y/Z

F: Toolholder reference point

Radius

Geometry

Length 2

Base Length 2

Base

Length

1

Geometry

Length

1

∝

Loading...

Loading...